Lifting board device of drying machine

A lifting plate and drying machine technology, which is applied in the direction of drying, drying solid materials, lighting and heating equipment, etc., can solve the problem of affecting the normal operation and use effect of the equipment, short continuous operation time of the equipment, and adhesion of the secondary lifting device and other problems, to achieve the effect of reducing thermal voids, reducing production costs and maintenance costs, and reducing equipment weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to clearly illustrate the technical characteristics of this solution, the following describes this solution through a specific implementation and in conjunction with the accompanying drawings.

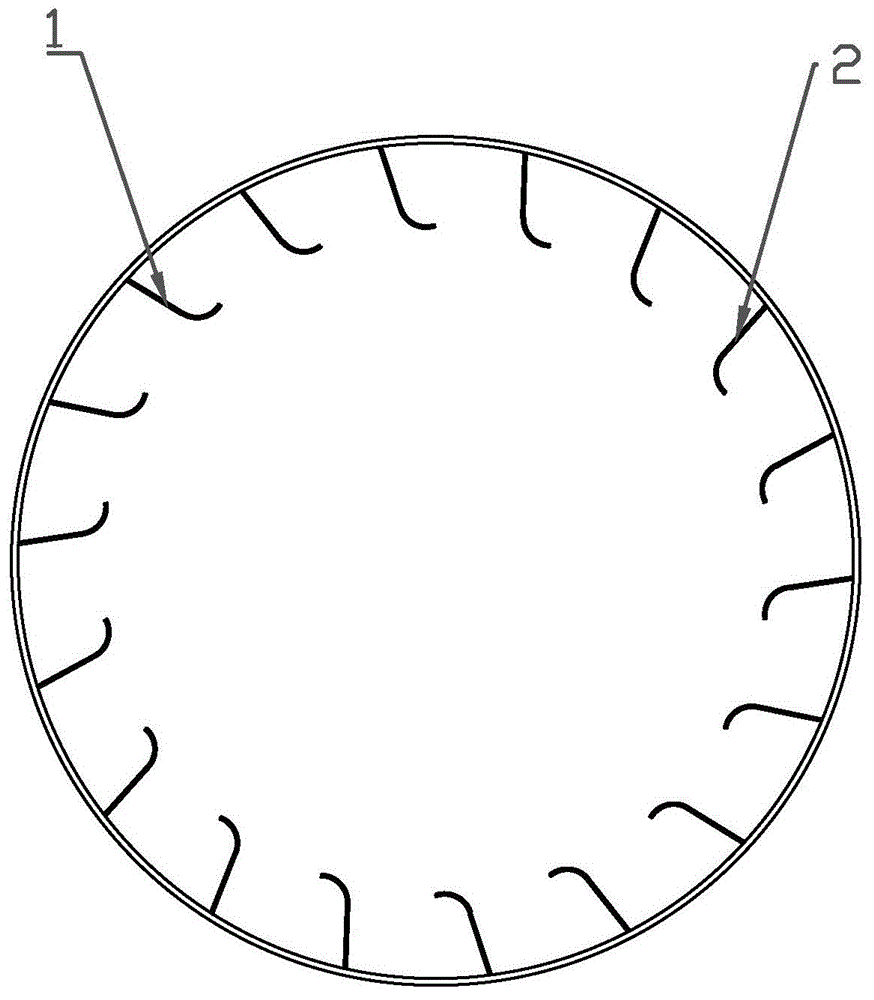

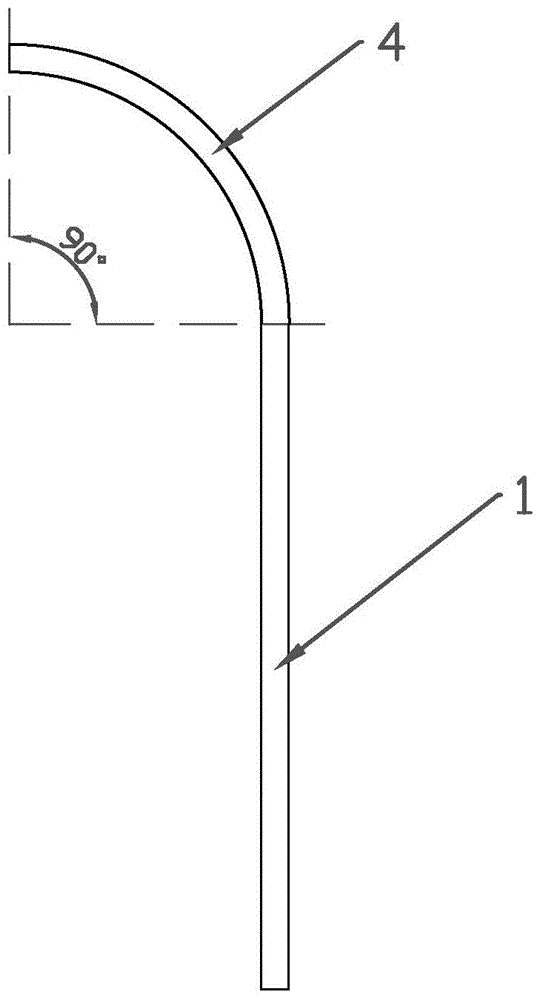

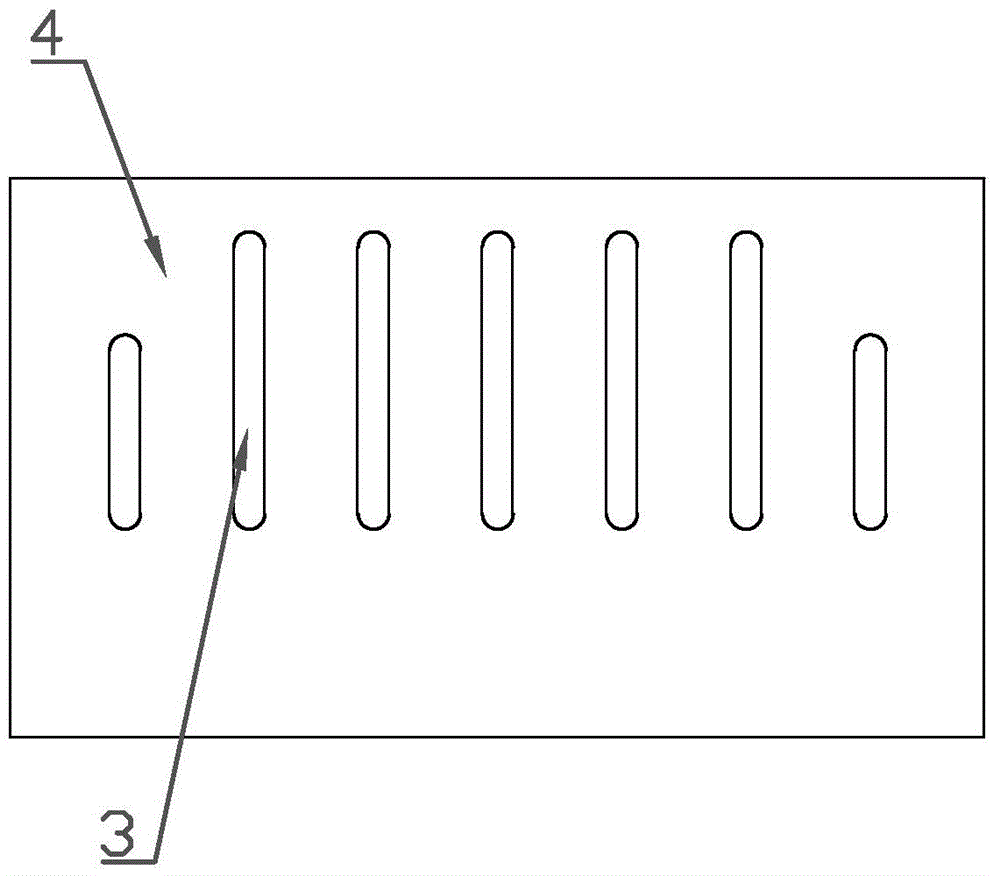

[0020] Such as Figure 1-4 As shown, a lifting plate device of a dryer of the present invention includes a lifting plate 1 and a drying cylinder 2 on which the lifting plate 1 is installed. The lifting plate 1 is arranged inside the drying cylinder 2 There are a plurality of said lifting plates 1 which are evenly distributed inside the drying cylinder 2. Said lifting plates 1 are steel lifting plates, and the upper end of the lifting plates 1 is curved in an arc shape. The bending angle of the bending part of the lifting plate 1 is 90°.

[0021] The connection between the lifting plate 1 and the drying cylinder 2 can be welded or screwed according to the actual situation. The lifting plate 1 can be installed on the drying cylinder 2. Ensure that the lifting plate 1 has the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com