Retaining grid and fuel assembly with such retaining grid

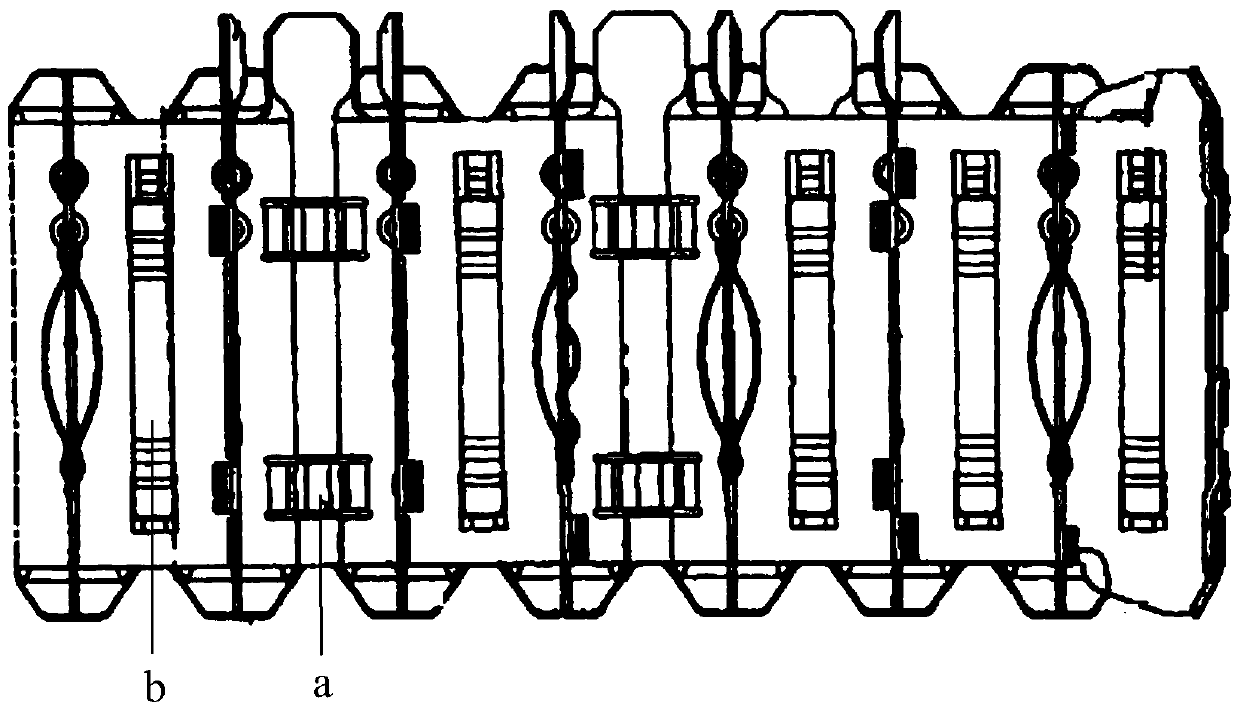

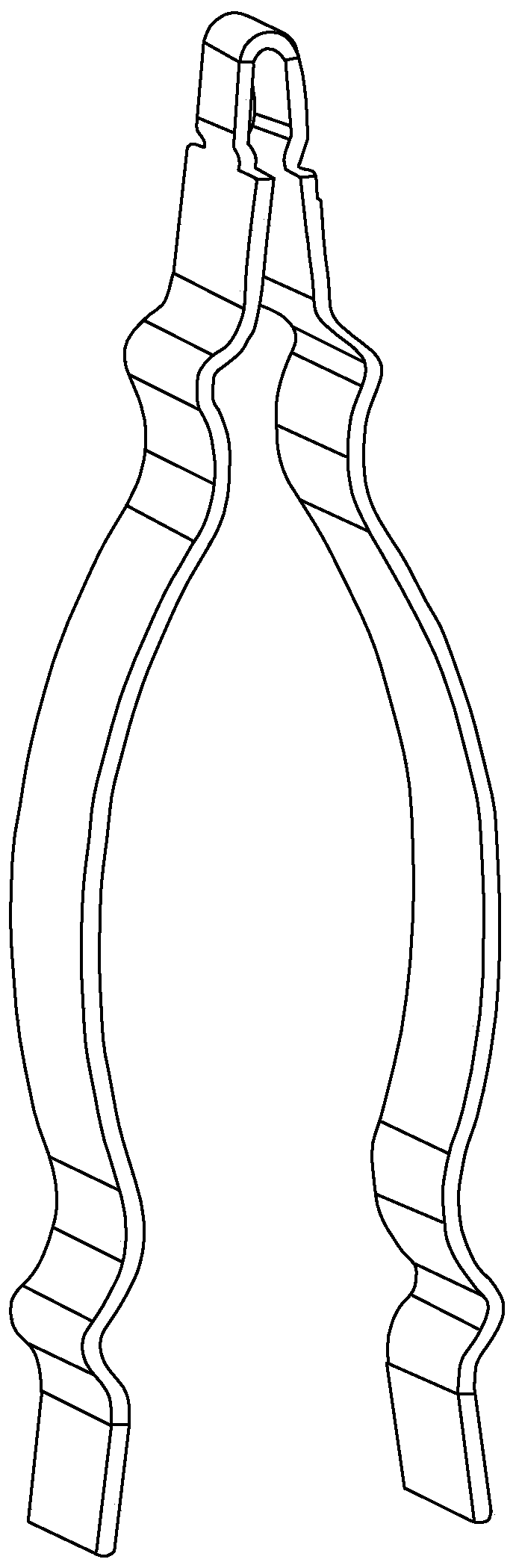

A technology for maintaining grids and grids, applied in the field of nuclear reactors, can solve the problems of high processing difficulty, increased pressure loss, uneven distribution of rigid convex a and spring b, etc., and achieves simple molding process, reduced pressure loss, and reduced pressure The effect of the upflow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

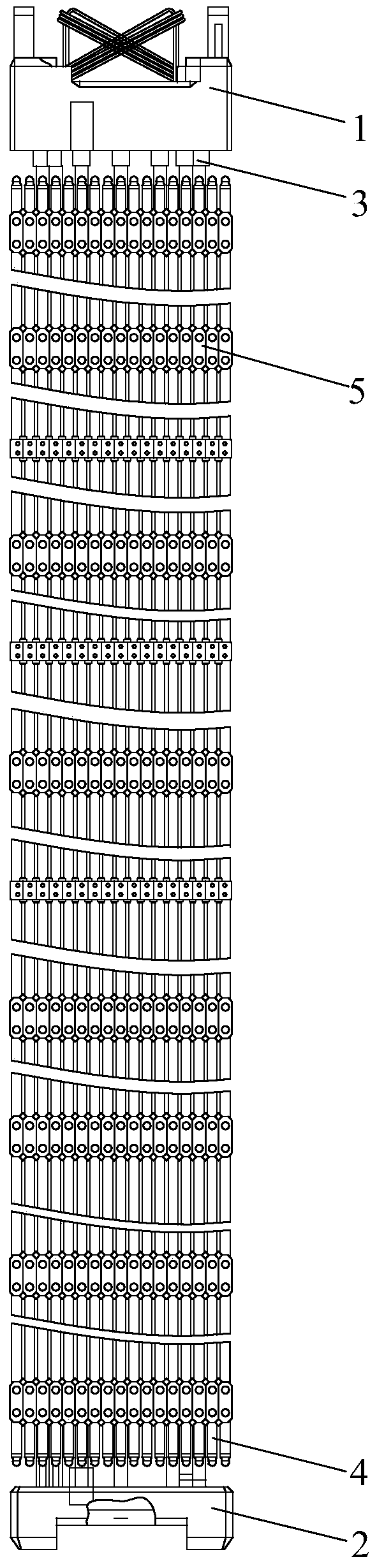

[0034] Such as image 3 As shown, the present invention discloses a light water reactor nuclear fuel assembly, comprising an upper tube base 1, a lower tube base 2, a plurality of control rod guide tubes 3, a plurality of fuel rods 4 and a plurality of holding grids 5, a plurality of The holding grids 5 are arranged in the vertical direction (the axial direction of the fuel rods 4), and a plurality of the control rod guide tubes 3 and the fuel rods 4 are respectively inserted in the holding grids 5, and the control rods guide The upper end of the tube 3 is fixed to the upper tube base 1 , and the lower end of the control rod guide tube 3 is fixed to the lower tube base 2 . In the reactor, the coolant flows into the fuel assembly from the lower tube base 2 along the axial direction of the fuel rod 4 from bottom to top, cools the fuel rod 4 and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com