Floor heating water division and water collection device

A water collector and floor heating technology, which is applied in the field of building floor heating equipment, can solve the problems of difficult temperature control, easy to affect flow, and inaccuracy, and achieve hydraulic balance, reliable sealing structure, and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

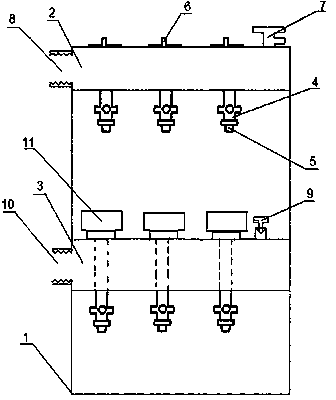

[0012] Such as figure 1 as shown,

[0013] The technical solution of the present invention is: a floor heating sub-collector, including a bracket 1, a water distribution pipe 2 installed on the bracket 1, and a water collection pipe 3. The water pipe 3, the water distribution pipe 2 and the water collection pipe 3 are on the same vertical plane, but the water distribution pipe 2 and the water collection pipe 3 are staggered in the vertical direction, so that the local heating pipelines connected to the bottom of the water distribution pipe 2 pass through, and the water distribution pipe 2 The bottoms of the water pipe 2 and the water collecting pipe 3 are provided with a plurality of branch pipes 4 with ball valves. One end of the branch pipes 4 with ball valves is fixed to the water distribution pipe 2 and the water collecting pipe 3 by welding, and the other end is an externally threaded inner conical surface, which is connected with a looper. One end of the ball head of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com