Reverse construction method waterproof grouting hole device and construction method

A construction method and technology of grouting holes, applied in infrastructure engineering, construction, etc., can solve problems such as hidden water leakage, achieve the effects of reducing waste, solving hidden dangers of water leakage, and avoiding construction inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

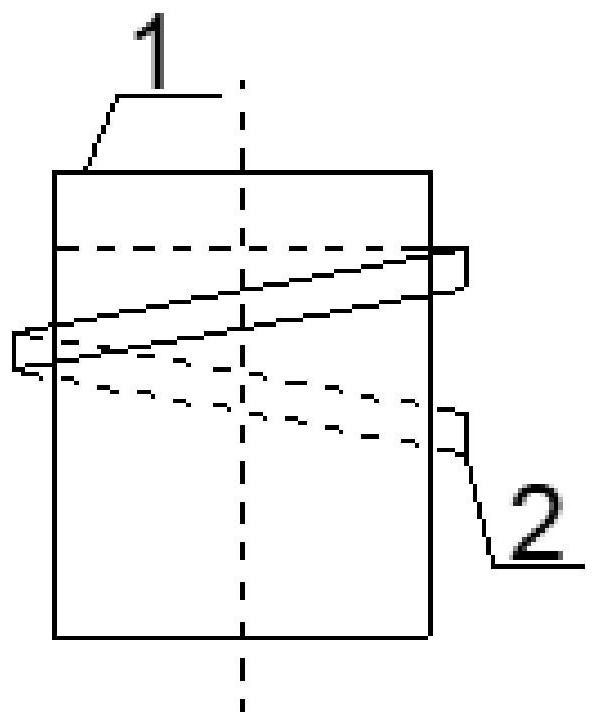

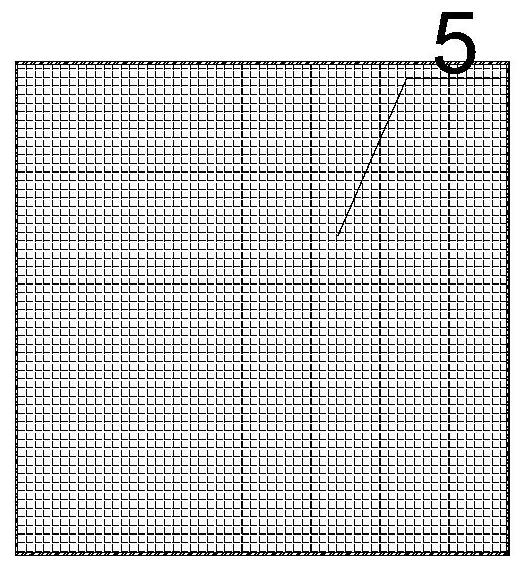

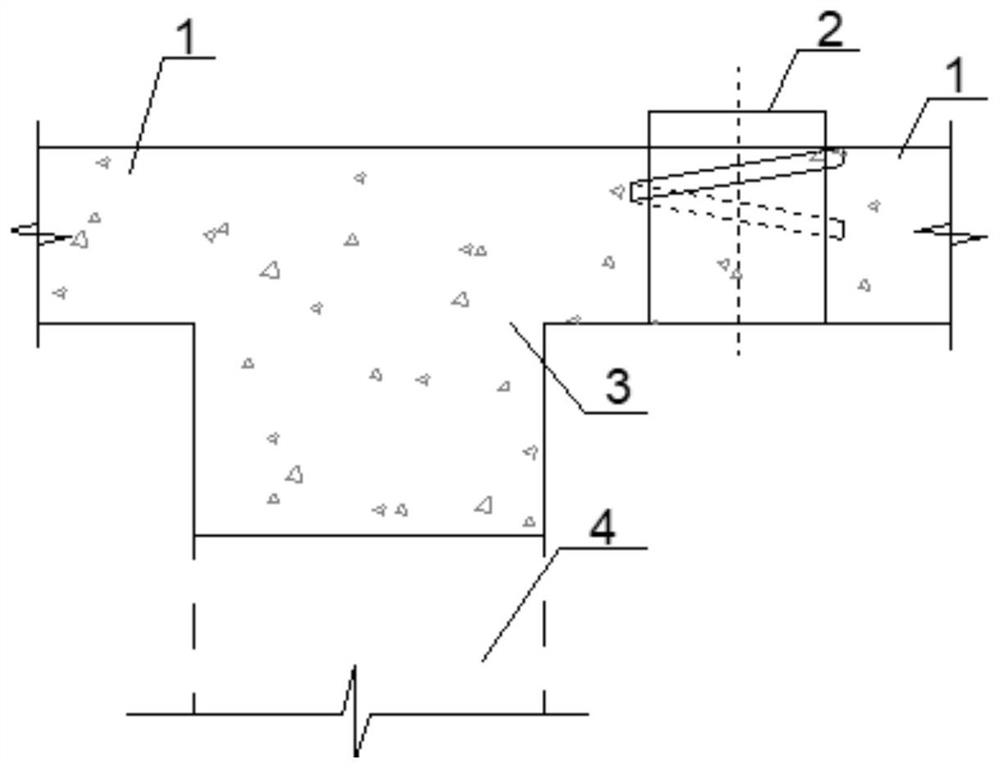

[0036] Combine below Figure 1 to Figure 4 , detailing the structural composition of the reverse method waterproof grouting hole device of the present invention.

[0037] Please refer to Figure 1 to Figure 4 , a waterproof grouting hole device of the reverse method, comprising a grouting pipe 2 matched with the grouting hole, a groove is provided on the outside of the grouting pipe 2, and the groove is arranged in a spiral shape; a grouting pipe cover plate 5 is provided on the top of the grouting pipe 2, The outer wall of the grouting pipe 2 is provided with an elevation control line.

[0038] Specifically, the reverse method waterproof grouting hole device provided in this embodiment mainly arranges spiral grooves on the outside of the grouting pipe 2, and adds water passages on the outer wall of the concrete through the spiral grooves to achieve the purpose of water-stopping. After the pouring is completed, the grouting pipe 2 is screwed out by rotation to achieve the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com