Cast-in-place concrete non-dismantling composite formwork heat insulation system and construction process thereof

A composite formwork and thermal insulation system technology, applied in the field of building thermal insulation, can solve problems such as water leakage at joints and hidden dangers of cold bridges, and achieve the effects of slowing down cold bridges, reducing the weight of buildings and improving thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

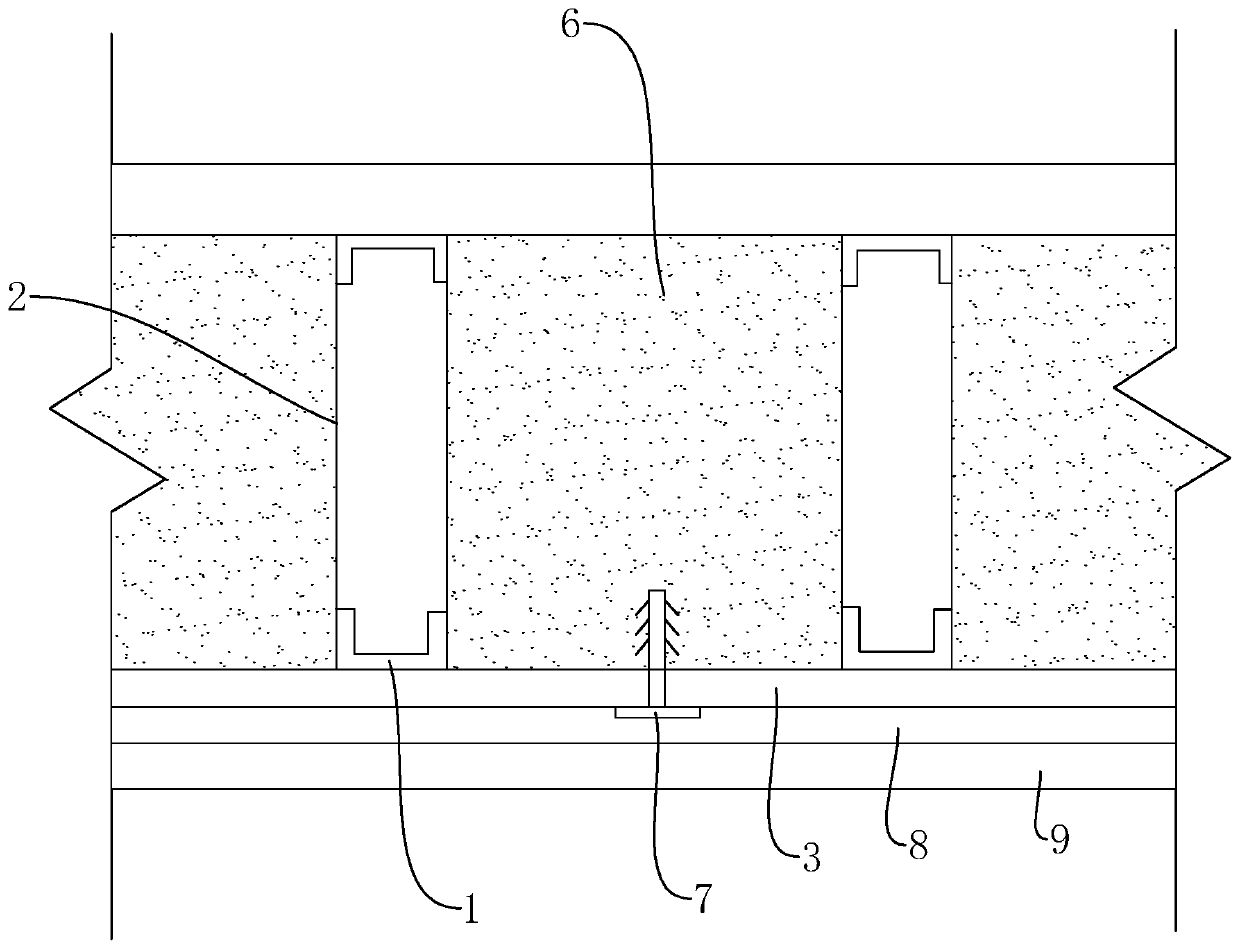

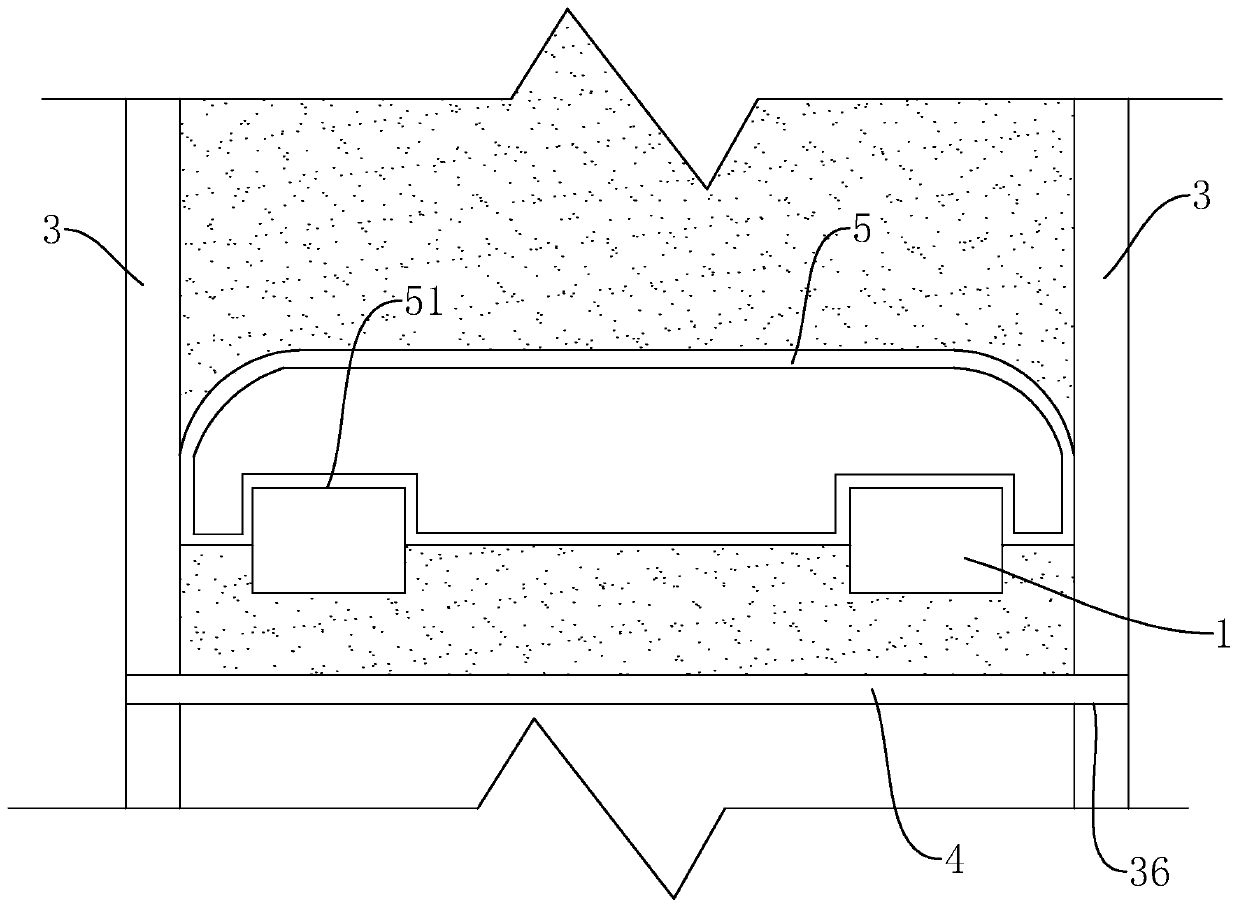

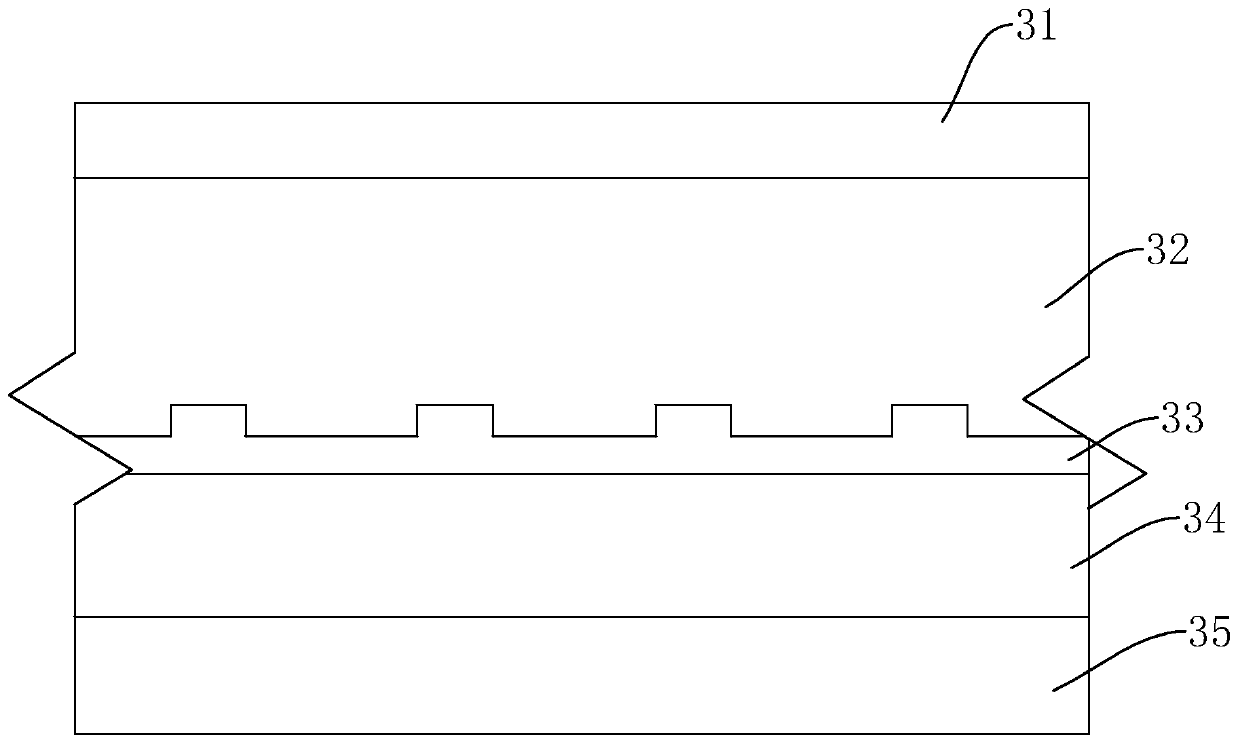

[0043] A kind of thermal insulation system of cast-in-place concrete without demolition compound formwork, refer to figure 1 and figure 2 , which includes double rows of light steel keels 1, double rows of light steel keels 1 are fixed on both sides of the steel beam as the wall skeleton, double rows of light steel keels 1 are connected by braces 2, two light steel keels 1 A supporting block 5 is arranged between them, and both ends of the bottom wall of the supporting block 5 are provided with limiting grooves 51, and the limiting grooves 51 are engaged with two corresponding light steel keels 1 on the same horizontal plane. There are multiple support blocks 5 distributed in a rectangular array. The thermal insulation formwork 3 is fixed on the outer side of the light steel keel 1 by the connecting member 4 to form the thermal insulation decorative surface of the outer wall, and the filler 6 is poured between the thermal insulation templates 3, and foamed polyurethane is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com