A fiber cement pipe brick, a wall and a method for making the fiber cement pipe brick

A technology of fiber cement and pipe bricks, which is applied to walls, manufacturing tools, building components, etc., can solve the problems of increasing construction strength, limiting popularization and application, and increasing costs, and achieves the effects of reducing building weight, convenient construction, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

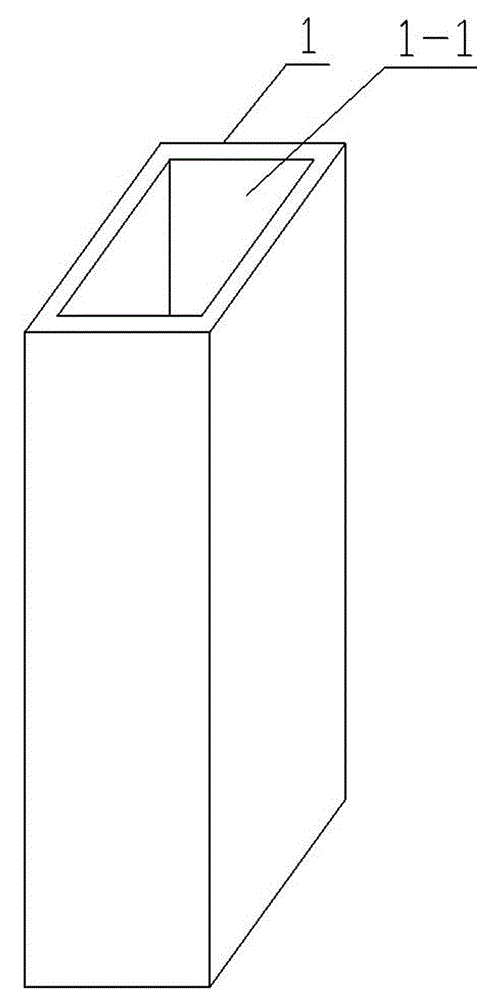

[0032] Such as figure 1 A fiber cement pipe brick is shown, which includes a tubular main body 1 with a rectangular parallelepiped shape. The pipe hole 1-1 of the tubular main body 1 is a through hole that runs through the top surface and the bottom surface of the tubular main body 1. The tubular main body 1 is made of fiber cement. Material.

[0033] figure 1 The production method of the fiber cement pipe brick shown includes the following steps: (1) mixing the raw materials to prepare the slurry; (2) taking the slurry from the mesh cage to make a sheet material, winding the sheet material in multiple layers and extruding it into a round Tubular wet billet, this step is the prior art; (3) Secondary forming the circular tubular wet billet into a tubular body 1 with a rectangular parallelepiped shape: (3-1) Figure 6 As shown, the circular tubular wet billet 4 is placed on the negative pressure bottom template 6, the central axis of the wet billet 4 is parallel to the negativ...

specific Embodiment 2

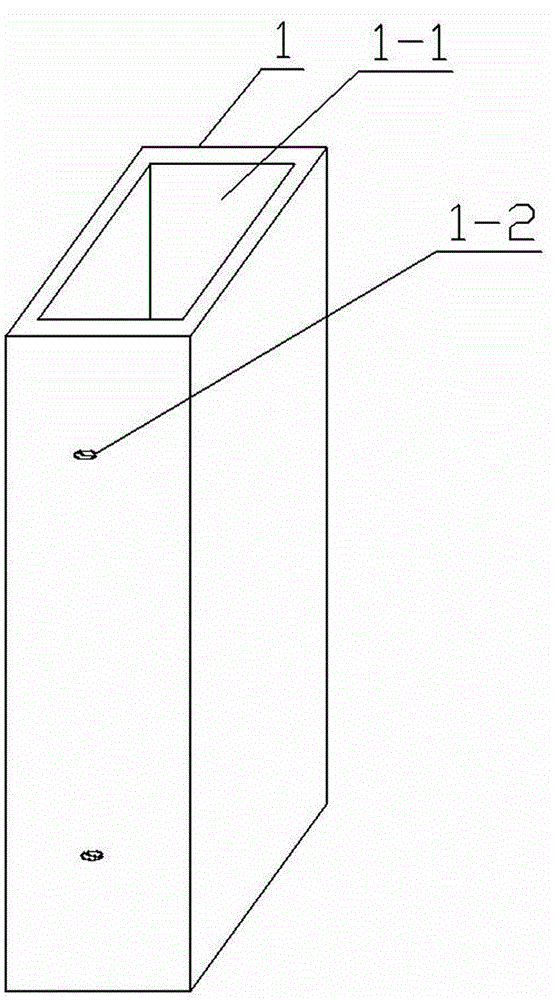

[0034] Such as figure 2 A fiber cement pipe brick is shown, which includes a tubular main body 1 with a rectangular parallelepiped shape. The pipe hole 1-1 of the tubular main body 1 is a through hole that runs through the top surface and the bottom surface of the tubular main body 1. The tubular main body 1 adopts fiber For cement material, the tubular body 1 has two adjacent side surfaces respectively provided with two upper and lower mounting holes 1-2 communicating with the tube holes 1-1 of the tubular body 1 . The tubular body 1 is made of fiber cement material.

[0035] Such as Figure 4 As shown, the wall includes a row of figure 2As shown in the fiber cement pipe bricks, the row of fiber cement pipe bricks includes a plurality of fiber cement pipe bricks closely arranged in the length direction of the wall, the pipe holes 1-1 of the tubular main body 1 of the fiber cement pipe bricks are vertically arranged, and the adjacent fiber cement pipe bricks The cement pi...

specific Embodiment 3

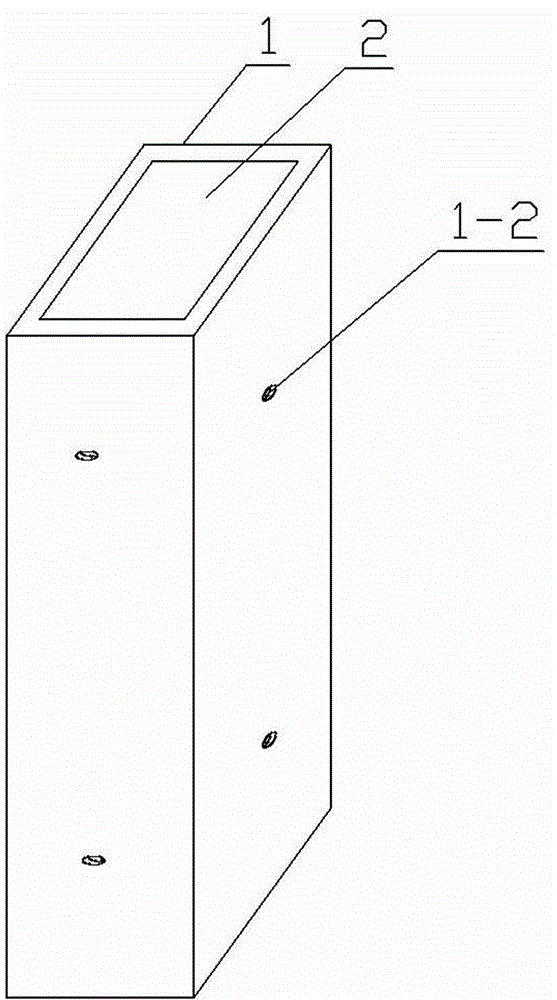

[0037] Such as image 3 A fiber cement pipe brick is shown, which includes a tubular main body 1 with a rectangular parallelepiped shape. The pipe hole 1-1 of the tubular main body 1 is a through hole that runs through the top surface and the bottom surface of the tubular main body 1. The tubular main body 1 adopts fiber Cement material, the tubular main body 1 has two upper and lower installation holes 1-2 communicating with the tube hole 1-1 of the tubular main body 1 on one side. The tubular body 1 is made of fiber cement material. The tube holes of the tubular main body 1 are filled with insulation strips 2 .

[0038] Such as Figure 5 As shown, the wall consists of two rows of fiber cement pipe bricks in the thickness direction, and the outer row is made of figure 2 The fiber cement pipe brick shown, but the insulation strip 2 is arranged in the pipe hole of the fiber cement pipe brick, and the inner row adopts image 3 As shown in the fiber cement pipe bricks, each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com