Joint device of underground diaphragm wall and construction method thereof

A technology of underground diaphragm wall and joint device, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve problems such as the hidden danger of water leakage at the joint of underground diaphragm wall, achieve convenient docking installation and positioning, solve the hidden danger of water leakage, and facilitate The effect of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

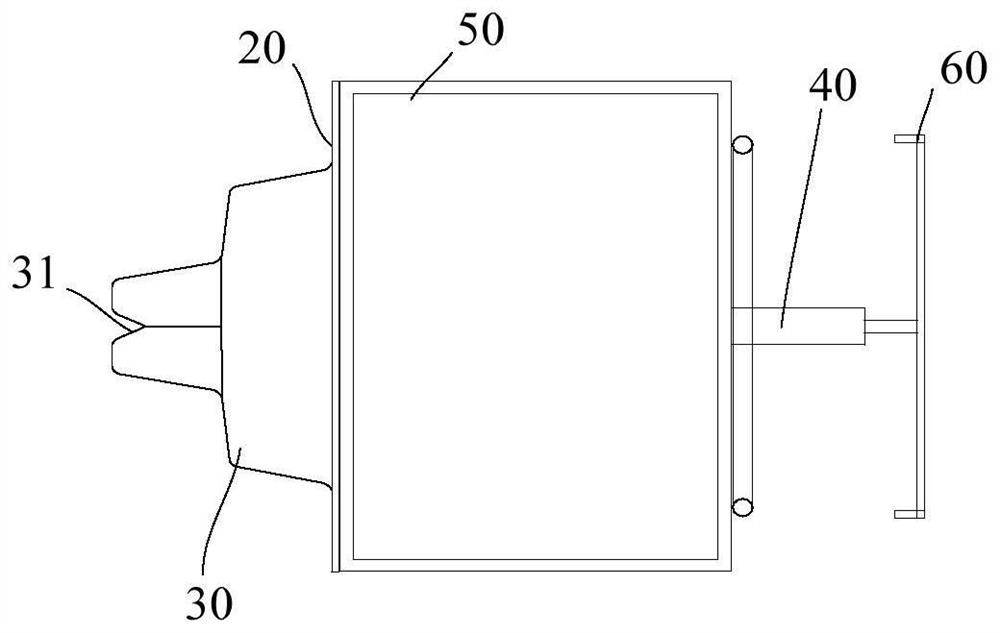

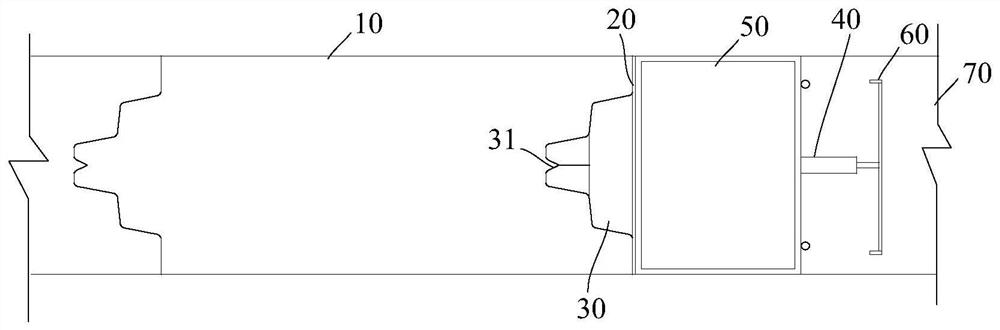

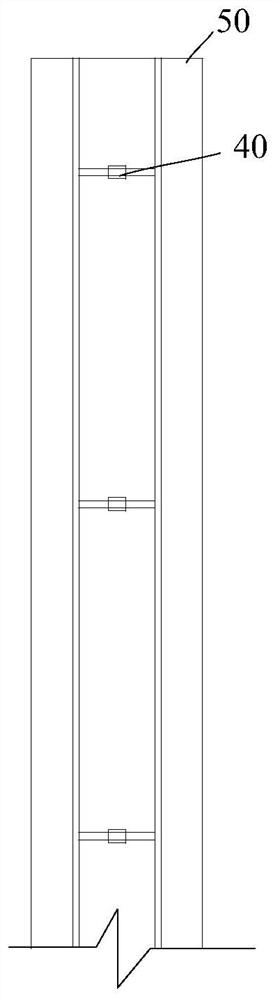

[0035] refer to figure 1 , shows a schematic structural view of the joint device of the underground continuous wall of the present invention. refer to figure 2 , shows a top view of the joint device of the underground continuous wall of the present invention installed in the groove section. combine figure 1 and figure 2 As shown, in general, the underground diaphragm wall is composed of many wall sections. In order to maintain the continuous construction between the wall sections, a trough section with a steel cage is formed first, and the device is fixed at the end of the trough section. , pour concrete into the groove section to form a wall section, take out the device after the initial setting, thereby forming a joint groove on the wall section, so that the adjacent wall section can be spliced through the joint groove and the wall se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com