Connecting method for pipeline joint

A technology for pipe joints and connection methods, which is applied to non-detachable pipe connections, pipes/pipe joints/fittings, elbows, etc., which can solve problems such as unresolved joints and inconvenient use, and achieve reduced raw material consumption, convenient installation, and overall good test performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

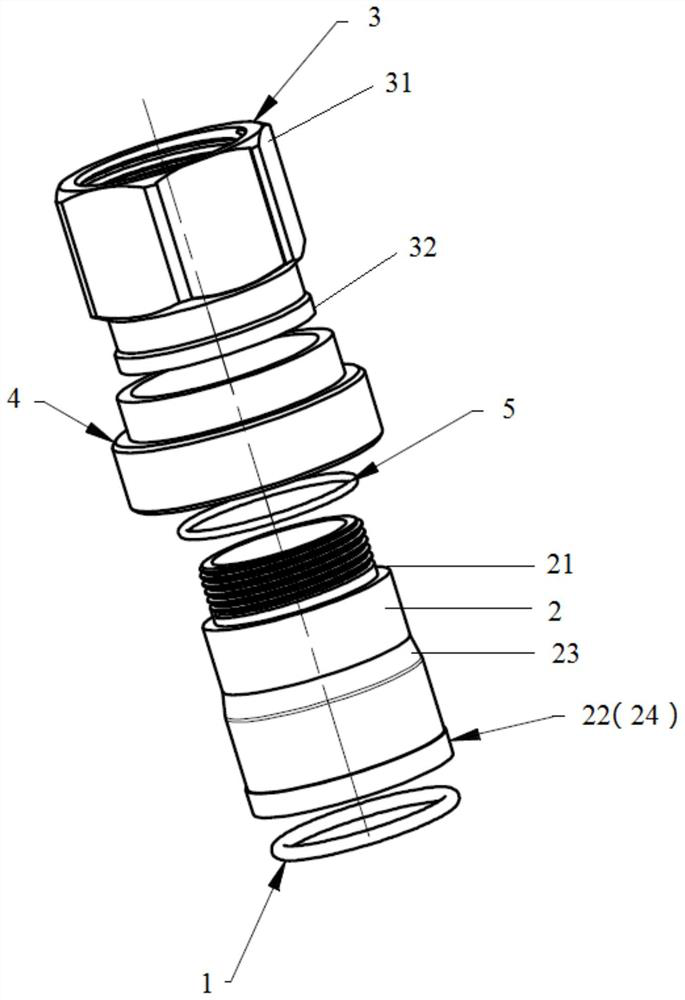

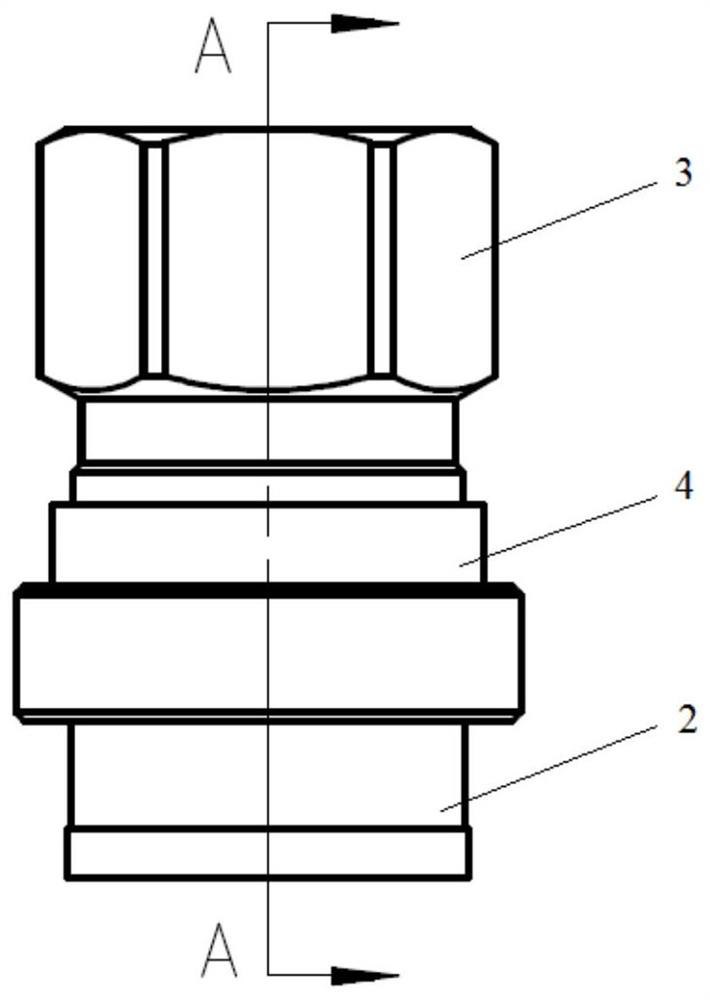

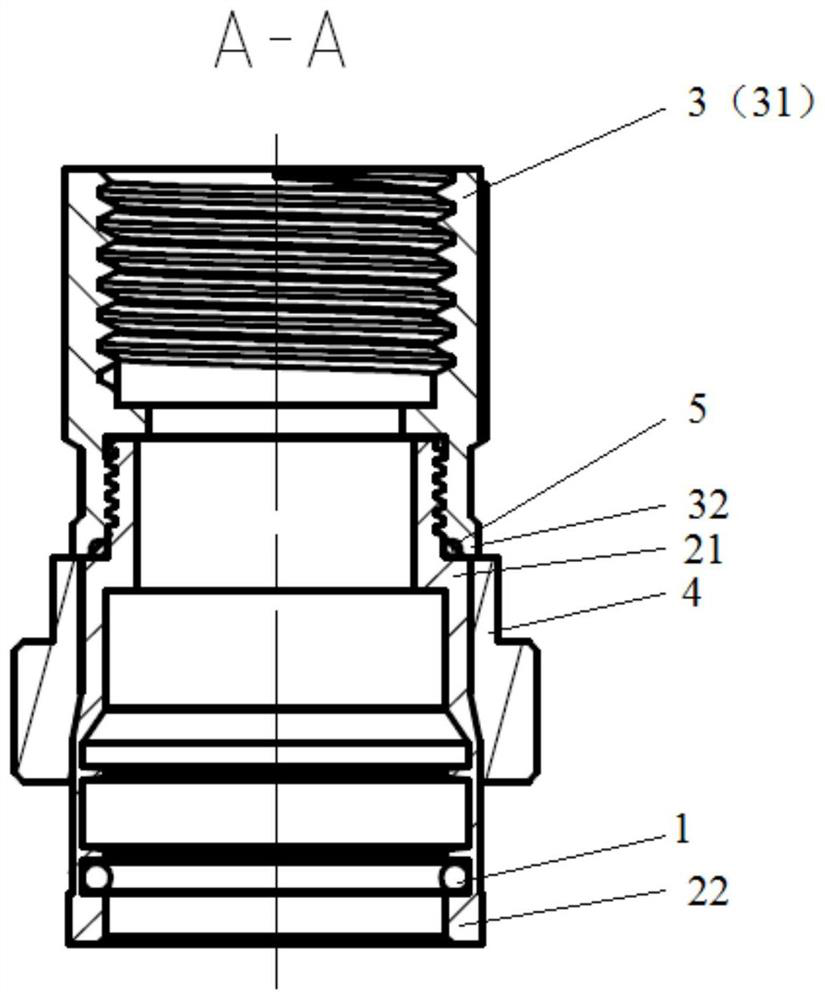

[0035] Such as Figure 1-8As shown, the present invention specifically provides a method for connecting a pipe joint, the pipe joint is used to connect with at least one metal pipe, and the pipe joint includes at least one external O-ring (1), at least one metal connector ( 2), a metal joint body (3) and at least one metal wedge cap (4), the external O-ring (1) is used for the connection and sealing of the pipe joint and the metal pipe, and the connection head (2 ) and the joint body (3) are interconnected; the joint head (2) includes a joint end (21) and a pipe end (22), and the joint body (3) includes a main body end (31) and at least one internal end ( 32), the main body end (31) is used for the connection between the pipe joint and the faucet or other workpieces, or the main body end (31) is used for connecting multiple internal connection ends (32), and the internal connection ends (32) Used to connect and cooperate with the joint end (21); the radial inner wall of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com