External corner unit plate connecting structure for energy-saving curtain wall

A connection structure and corner connection technology, applied to walls, building components, building structures, etc., can solve the problems of water leakage, unstable structure, and excessive aluminum materials, so as to solve the hidden danger of water leakage, save materials and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

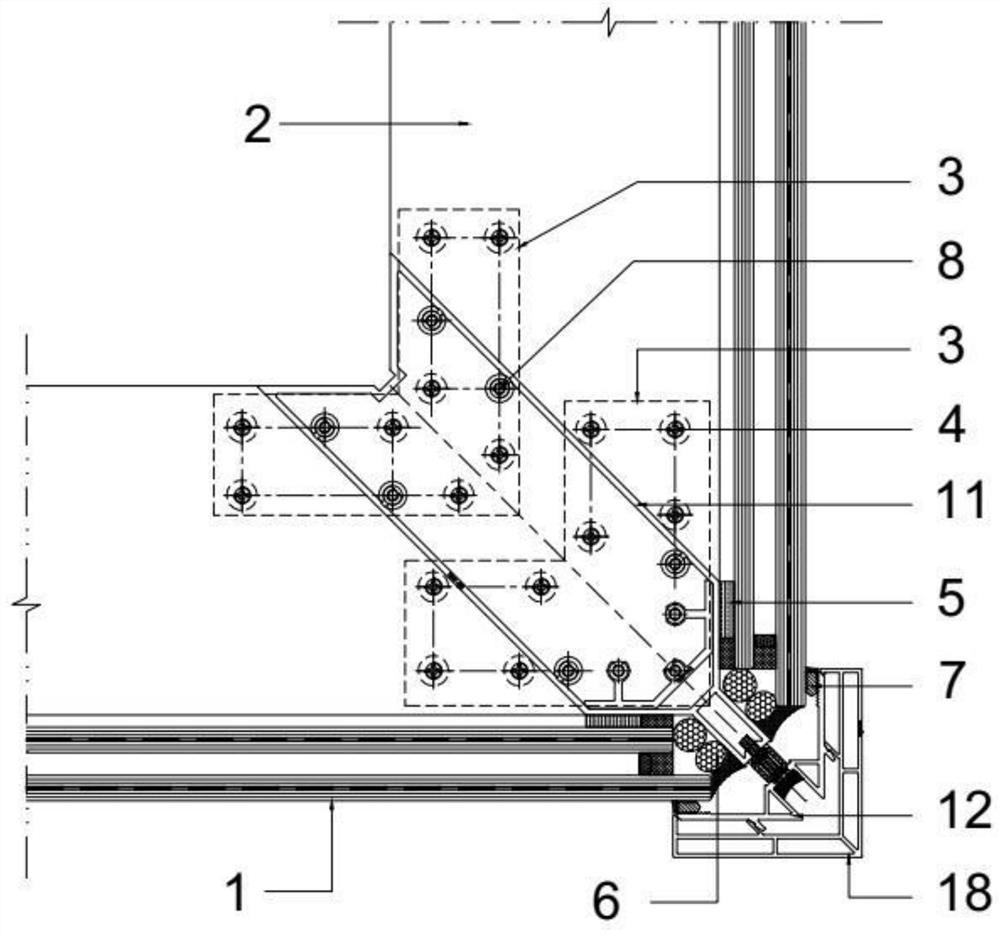

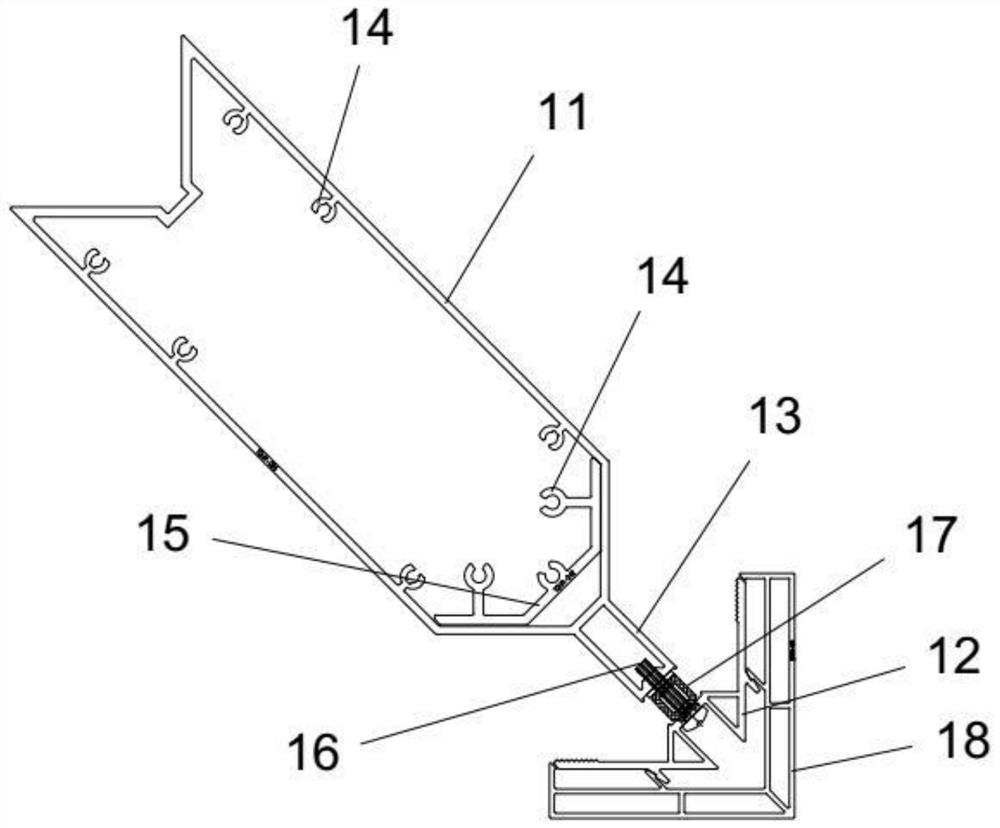

[0017] Such as Figure 1-2 As shown in the present invention, an external corner unit panel connection structure of an energy-saving curtain wall includes an upper external corner beam assembly, a lower external corner beam assembly, a column connection assembly and an external corner curtain wall glass 1; the upper external corner beam assembly The external corner beam components of the lower layer are spliced by two beam profiles 2 respectively arranged on both sides of the external corner of the curtain wall. The beam profiles 2 on both sides are at 90° or other angles. The curtain wall glass 1 and the external corner curtain wall glass 1 cooperate with the beam profile 2 through structures such as rubber strips or attached frames.

[0018] Both the upper male corner beam assembly and the lower male corner beam assembly are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com