Modular Fan Coil System

A fan coil unit, modular technology, applied in heating and ventilation control systems, heating and ventilation safety systems, air conditioning systems, etc., can solve problems such as troublesome maintenance, increase cost, increase pipelines, etc., and achieve easy installation and maintenance. , Reduce the possibility of water leakage, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

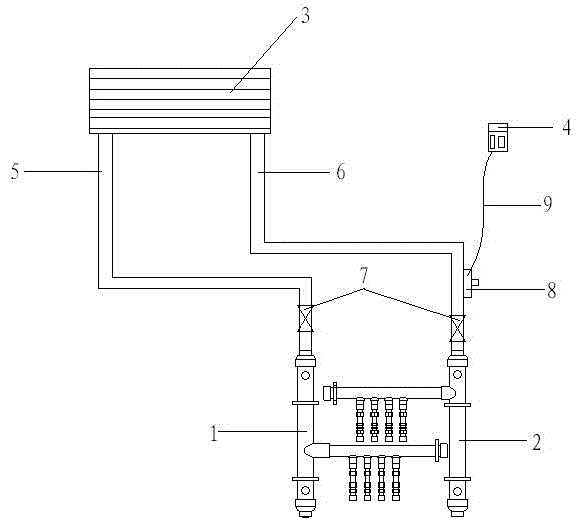

[0014] see figure 1 , figure 1 It is a structural schematic diagram of a preferred embodiment of the modularized fan coil system of the present invention.

[0015] The present invention provides a modular fan coil system, which includes a sub-water collection unit, a fan coil unit, a valve assembly unit, an electric valve signal line 9 and a connecting branch pipe unit; the sub-water collection unit includes a water separator 1 and a water collection unit water heater 2; the fan coil unit includes a fan coil unit 3 and a fan coil thermostat 4; the valve assembly unit includes a gate valve 5 and an electric two-way valve 6; the connecting branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com