Magnetic toner

一种调色剂、磁性的技术,应用在磁性调色剂领域,能够解决定影拖尾增加等问题,达到稳定图像浓度、防止定影拖尾的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0402] (image forming equipment)

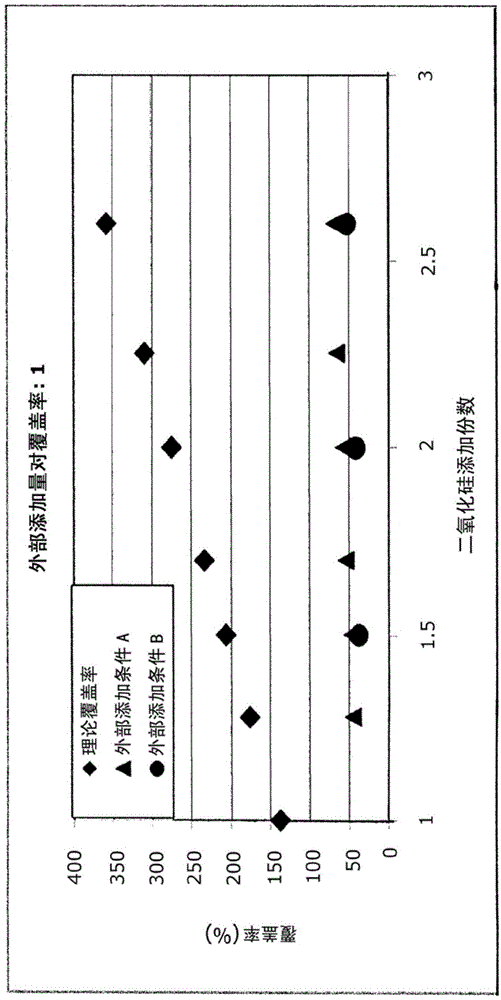

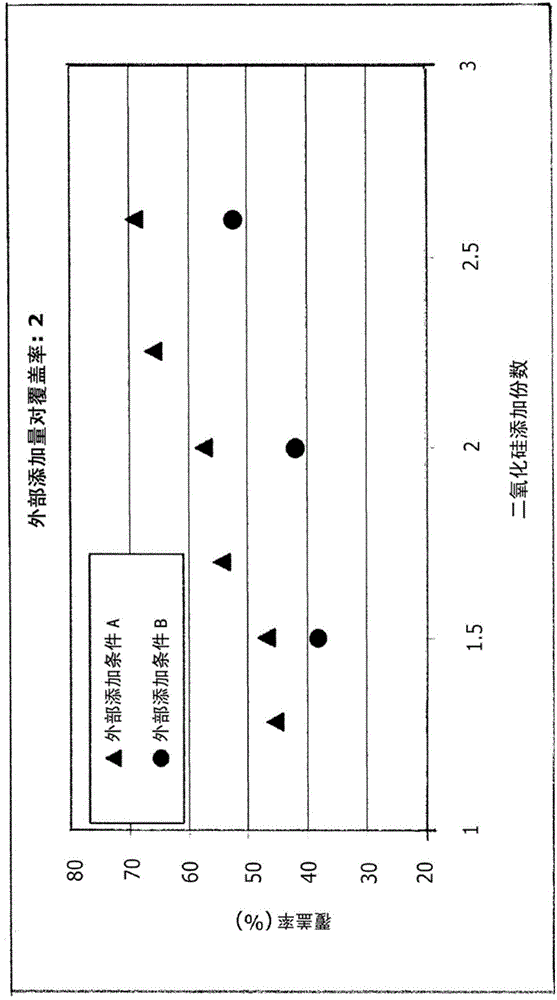

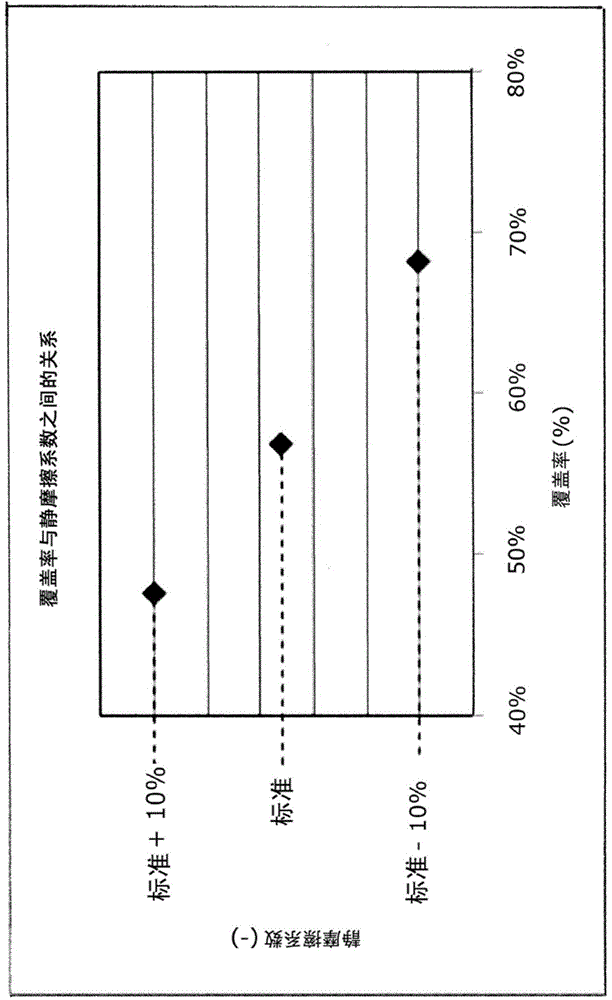

[0403] The image forming apparatus was LBP-3100 (Canon, Inc.) equipped with a small-diameter developing sleeve having a diameter of 10 mm; the printing speed thereof was changed from 16 sheets / minute to 20 sheets / minute. The equipment was also modified so that the fixing temperature of the fixing unit was lowered by 35°C. FOX RIVER BOND paper (105g / m 2 ) is used as a recording medium. In an image forming apparatus equipped with a small-diameter developing sleeve, durability can be strictly evaluated by changing the printing speed to 20 sheets / minute. In addition, by using the above-mentioned recording medium that exhibits a large amount of water absorption and provides poor transfer of the magnetic toner at the fixing temperature, and by changing the developing sleeve to a small-diameter developing sleeve, lowering the fixing temperature, and under a high-temperature, high-humidity environment Continuous paper feeding evaluation is perform...

Embodiment 2-33 and comparative example 1-29

[0438] Toner evaluation was performed under the same conditions as in Example 1, using Magnetic Toner 2-33 and Comparative Magnetic Toner 1-29 as the magnetic toner. The results of the evaluation are shown in Table 7. In Comparative Examples 7 and 9, there were very many free silica fine particles on the developing sleeve and image defects were generated in the form of vertical stripes. When the magnetic toner particles 20 used in Comparative Example 12 were left overnight in a high-temperature, high-humidity environment, a large number of aggregates were generated by the magnetic toner and image defects were generated in the form of vertical stripes.

[0439] [Table 7-1]

[0440]

[0441] [Table 7-2]

[0442]

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com