Toner for electrophotography

A technology of electrophotography and toner, applied in the direction of developer, electrography, instrument, etc., can solve the problems of image density drop, toner charging, toner charge increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0122] (Preparation method of binder resin fine particle dispersion liquid)

[0123] The binder resin material is roughly pulverized using a pulverizer such as a turbo pulverizer, and the obtained coarse pulverized product is dispersed in an aqueous medium such as ion-exchanged water, and heated in this dispersed state. The heating temperature is preferably a temperature higher than Tm of the binder resin by 10°C or higher and lower than 200°C. Then, after the heating is completed, a strong shear force is applied using a high-speed shear emulsification device (for example, "CLEARMIX" manufactured by M-Technique Co., Ltd.), to obtain a binder resin fine particle dispersion.

[0124] The volume median diameter of the binder resin particles (D 50 ) is preferably 1 μm or less, more preferably 0.05 μm or more and 0.5 μm or less. If the volume median diameter (D 50 ) within such a range, it is easy to prepare nuclei with a narrow particle size distribution and a uniform shape. I...

Embodiment 1

[0188] (Preparation of low melting toner core)

[0189] A polyester resin was produced by reacting terephthalic acid with an alcohol (bisphenol A ethylene oxide adduct) having bisphenol A as a skeleton to which ethylene oxide was added. The polyester resin had an OHV value of 20 mgKOH / g, an AV of 40 mgKOH / g, a Tm of 100°C, and a Tg of 48°C. With respect to 100 parts by mass of the polyester resin, 5 parts by mass of C.I. Pigment Blue 15:3 (phthalocyanine pigment) was blended as a colorant, and 10 parts by mass of ester wax ("WEP-3" manufactured by NOF Corporation) was blended as a release agent. After mixing with a mixer (FM mixer), the flakes kneaded by a twin-screw extruder ("PCM-30" manufactured by Ikegai Co., Ltd.) were mixed with a mechanical pulverizer ("Turbo Pulverizer" manufactured by Freund Turbo Co., Ltd.). ") pulverized to 6 microns. Then, it was classified using a classifier ("Elbow-Jet" manufactured by Nippon Steel Mining Co., Ltd.), and the volume median diame...

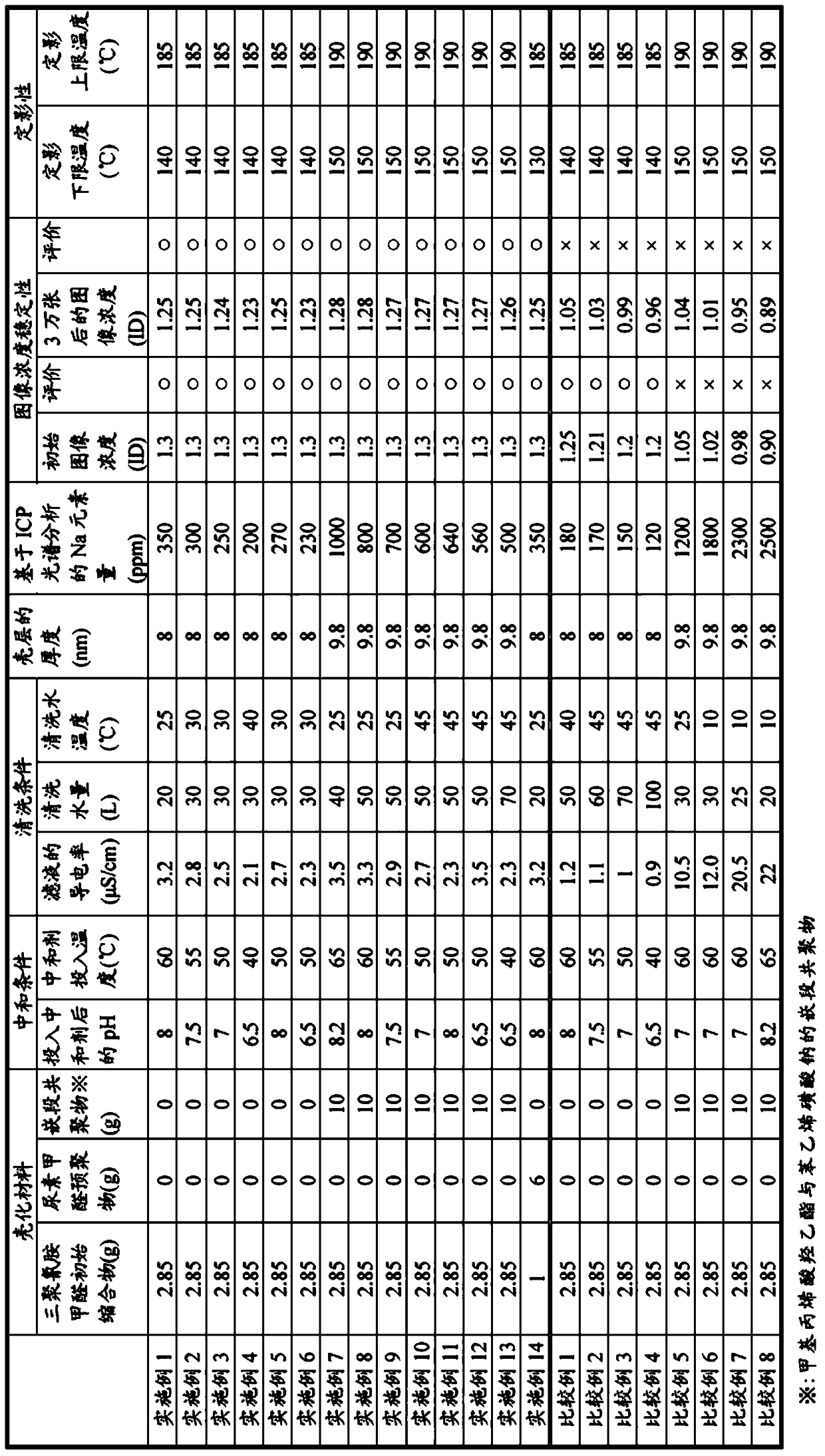

Embodiment 2~6

[0217] As shown in the following Table 2, except that the neutralization conditions (pH after neutralizing agent input, temperature of neutralizing agent input) and cleaning conditions (conductivity of filtrate, amount of cleaning water, temperature of cleaning water) were changed, the others were the same as in the examples. 1 Similarly, a developer was produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com