Mounting tool for valve bearings in various sizes

An installation tool, multi-dimensional technology, applied in the oil field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

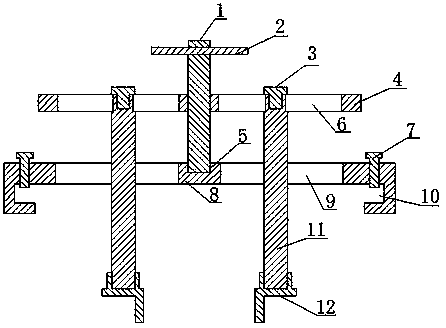

[0021] Such as figure 1 , figure 2 Installation tools for valve bearings of multiple sizes shown, including:

[0022] The horizontal positioning plate 8 is provided with a positioning groove 5 in the middle of the horizontal positioning plate 8, and the horizontal positioning plate 8 is located at both ends of the positioning groove 5 and is equidistantly provided with a limiting groove 9;

[0023] The linkage plate 4 is provided with a threaded through hole in the middle of the linkage plate 4, and movable grooves 6 are symmetrically arranged on both sides of the linkage plate 4 with the central axis of the threaded through hole as the center;

[0024] The lower end of the screw 1 is positioned in the positioning groove 5 after the screw 1 cooperates with the threaded through hole of the linkage plate 4;

[0025] Vertical straight rod 11, vertical straight rod 11 equidistantly arranged on both sides of screw rod 1, and the upper end of described vertical straight rod 11 p...

Embodiment 2

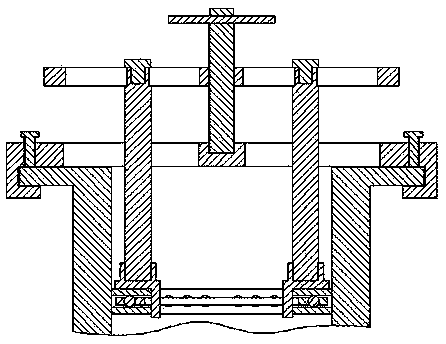

[0031] This embodiment adds the following structure on the basis of Embodiment 1: both ends of the horizontal positioning plate 8 are bent to form a bayonet 10 , and the horizontal positioning plate 8 is provided with a locking nut 7 corresponding to the bayonet 10 .

[0032] In this embodiment, in order to facilitate the fixing of the horizontal positioning plate 8, reduce the difficulty of tool fixing, and avoid the trouble of installing the fixing device, both ends of the horizontal positioning plate 8 are bent to form a bayonet 10, and the bayonet 10 is clamped on the upper end of the valve. The horizontal positioning plate 8 can be firmly fixed on the flange plate and locked by the lock nut, which is convenient for bearing installation.

Embodiment 3

[0034] In this embodiment, the following structure is optimized on the basis of embodiment 1 or embodiment 2, specifically: the lower end of the positioning block 12 has an L-shaped structure, and the upper end of the positioning block 12 is screwed to the lower end of the vertical rod 11 .

[0035] In this embodiment, the lower end of the positioning block 12 has an L-shaped structure, and the gaps of the L-shaped structures of the two positioning blocks 12 are arranged in reverse. When positioning, one side of the L-shaped structure of the bearing is located at the upper end of the bearing, and the other side is located at the inner circumference of the bearing. Clamp and position the bearing to keep it horizontal, and the bearing can be pressed tightly, so that the fixing and positioning effects are good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com