Automatic pressure gel forming device of epoxy resin

An automatic pressure gel and molding device technology, applied in the field of epoxy resin automatic pressure gel molding device, can solve the problems of low product qualification rate, frequent mold replacement, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

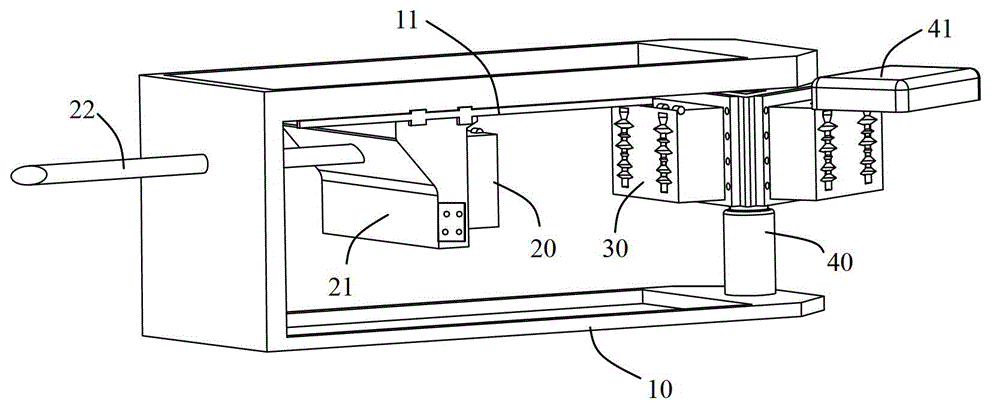

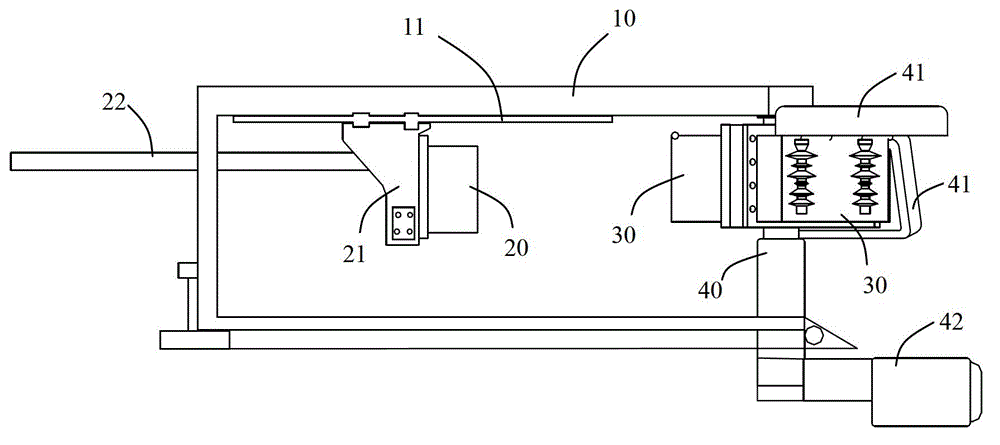

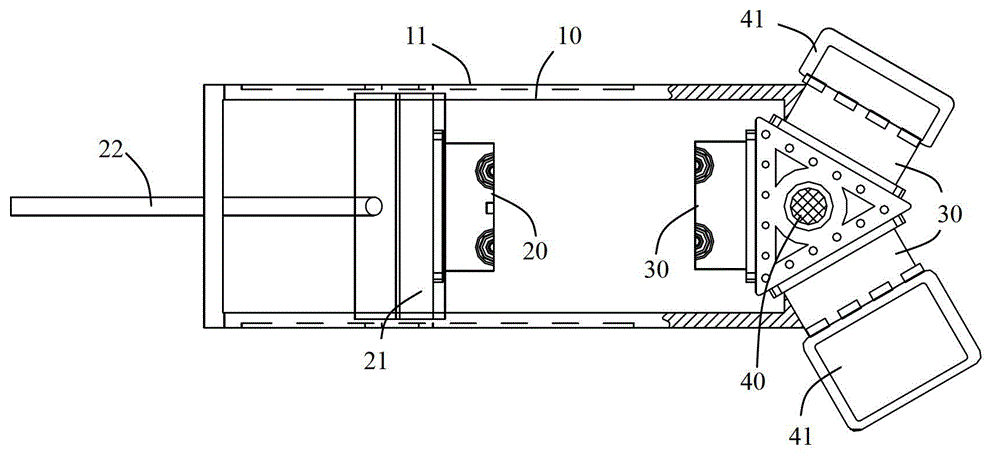

[0012] see Figure 1~3 The epoxy resin automatic pressure gel molding device of the present invention comprises a frame 10, a movable mold 20, a fixed mold 30 and a rotating mechanism 40, the frame 10 is provided with a guide rail 11, and the guide rail 11 is provided with a The moving frame 21 that moves on the guide rail 11, the movable mold 20 is fixedly mounted on the moving frame 21, the rotating mechanism 40 is rotatably mounted on the frame 10, and a plurality of the fixed The mold 30 is mounted on the rotating mechanism 40 .

[0013] The fixed molds 30 are evenly distributed along the circumference of the rotating mechanism 40, each of the fixed molds 30 can cooperate with the movable mold 20 to form a forming mold, and the rotating mechanism 40 rotates so that one of the fixed molds 30 stops. At the position where the movable mold 20 and the mould can be connected, the movable mold 20 moves relative to the guide rail 11, so that the movable mold 20 faces the fixed mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com