Machine for separating product from material belt

A technology for separators and products, applied in the direction of presses, manufacturing tools, etc., can solve the problems of wasting human resources, wasting time and energy, occupying, etc., and achieve the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

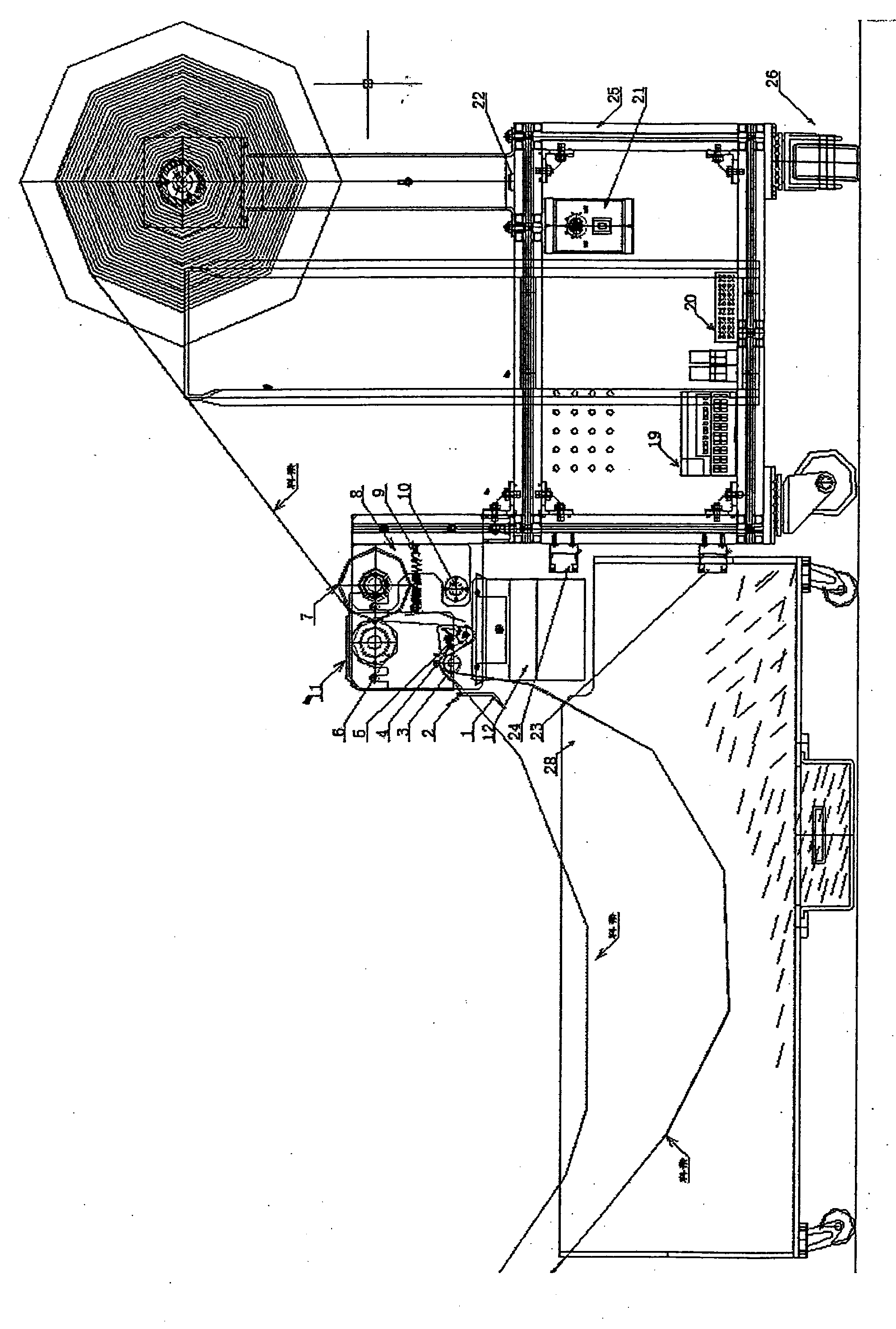

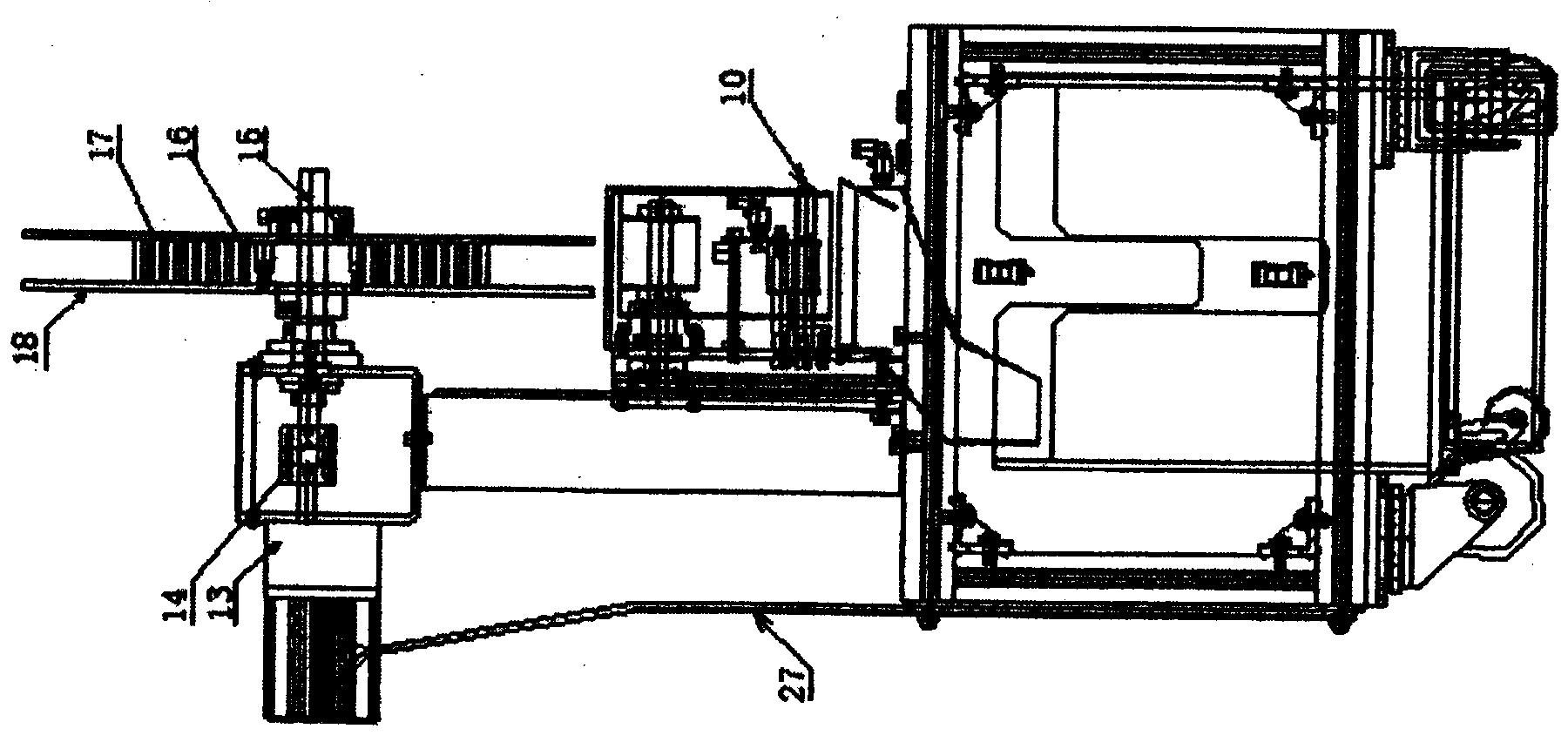

[0016] A kind of product and strip separating machine as shown in the figure,: by machine head part; Operation part; Control part; frame (25) and product collection box (28) part composition; machine head part is above the left side of frame , the running part is at the top right of the frame, the control part is in the frame, and the product collection box (28) part is below the machine head part;

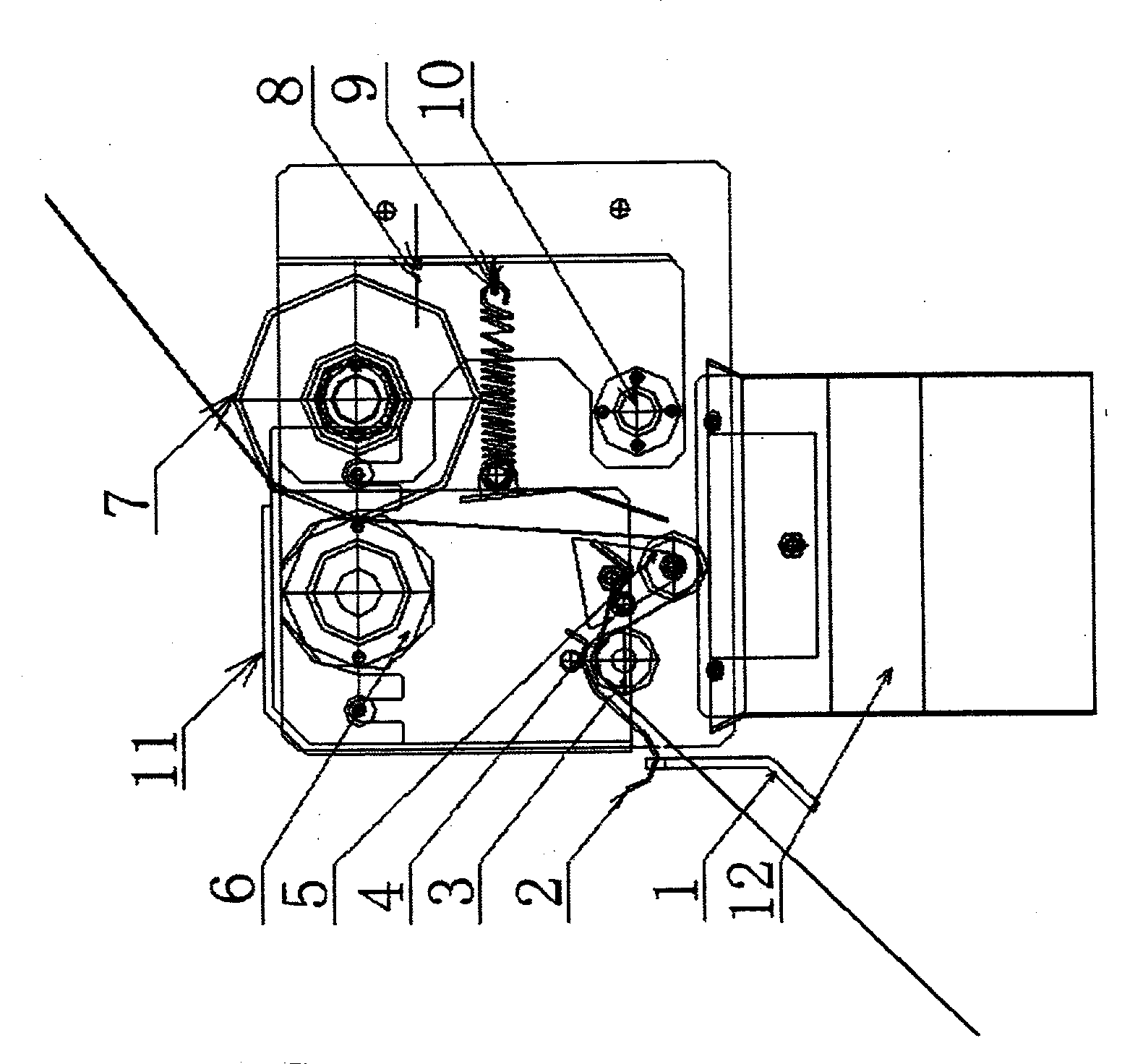

[0017] The head part: there is an organic glass cover (11) to prevent product splashing on the top, a hopper (12) on the bottom, a rotary pulley (6) on the top of the organic glass cover, and a close to the right of the rotary pulley The pinch wheel (7), the pinch wheel is contained on the pinch wheel bracket (8), the pinch wheel bracket shaft (10) is arranged under the pinch wheel bracket, the pinch wheel bracket shaft is contained on the machine head frame, and is pressed Wheel bracket connects extension spring (9), and extension spring is contained on the nose frame and makes p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com