Tamper for building

A tamping machine and construction technology, applied in construction, soil protection, infrastructure engineering, etc., can solve the problems of inconvenient use, low beating frequency, and poor compacting effect, and achieve convenient installation, high beating frequency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

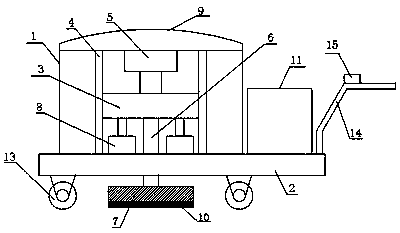

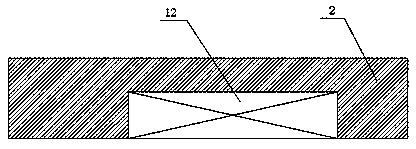

[0011] refer to figure 1 with figure 2 A construction tamping machine shown includes a working box 1, a base 2 and a slider 3, the working box 1 is installed on the base 2, and the working box 1 is provided with a Slide rail 4, described working box 1 is provided with first hydraulic device 5, and the output end of described first hydraulic device 5 is offset with the upper edge of slide block 3, and the bottom of described slide block 3 is connected with column 6, so The bottom of the column 6 is connected with a tamper 7, the base 2 is provided with a second hydraulic device 8, the output end of the second hydraulic device 8 is against the lower edge of the slider 3, and the upper part of the working box 1 is provided There is a dust cover 9, a wear-resistant layer 10 is provided on the working surface of the rammer 7, a controller 11 is provided on the base 2, and the first hydraulic device 5 and the second hydraulic device 8 are connected with the controller 11 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com