LNG liquid storage tank shock insulation layer

A liquid storage tank and shock-isolation layer technology, which is applied in the field of engineering foundation shock-isolation, can solve the problems of laminated rubber bearing damage, lack of shock-isolation effect, loss of shock-isolation effect, etc., to achieve reduced shaking wave height, excellent insulation Earthquake effect, the effect of saving project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] This embodiment provides a shock-isolation layer for an LNG liquid storage tank, which is used to provide shock-isolation support for a large liquid storage tank storing LNG.

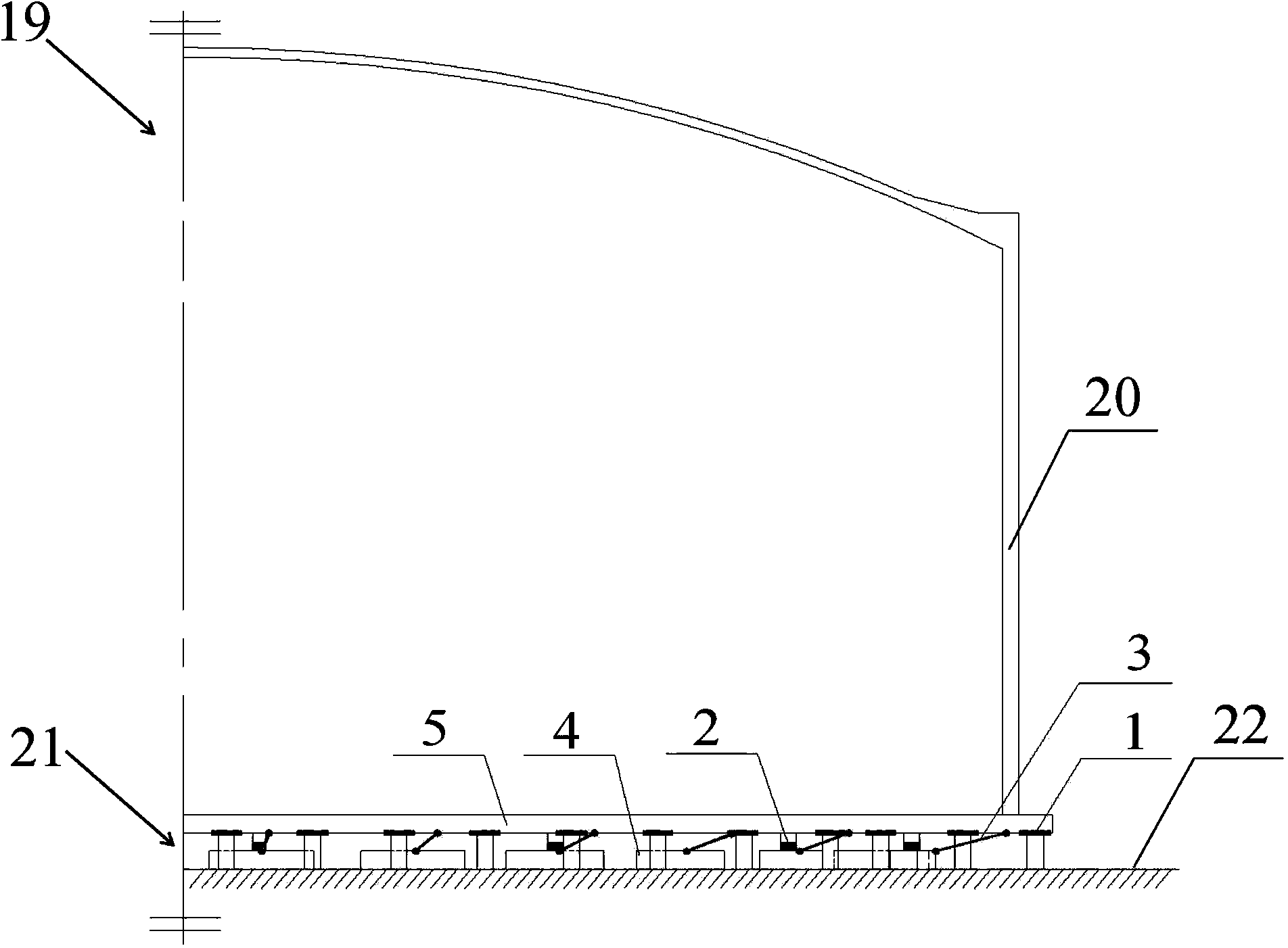

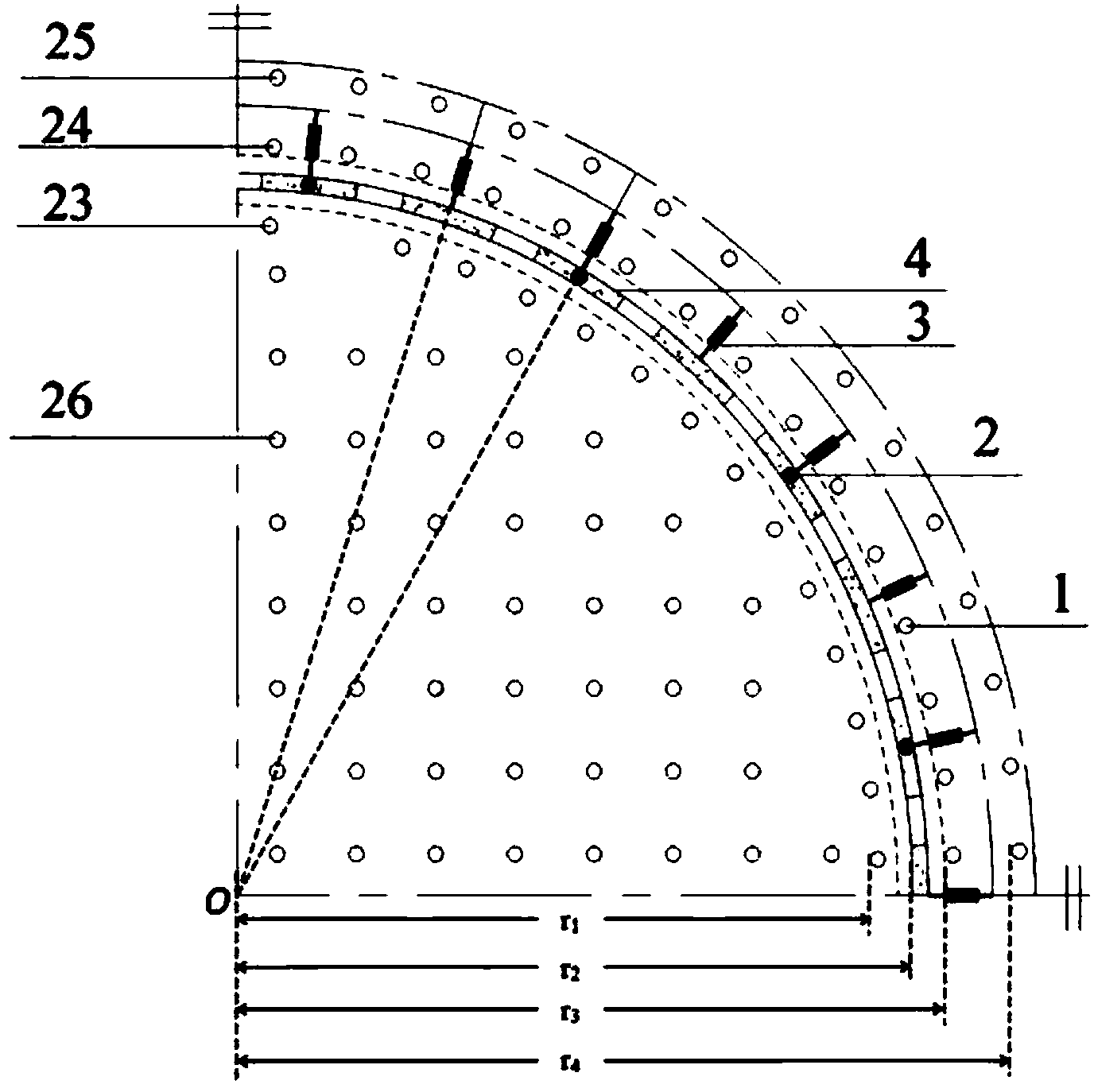

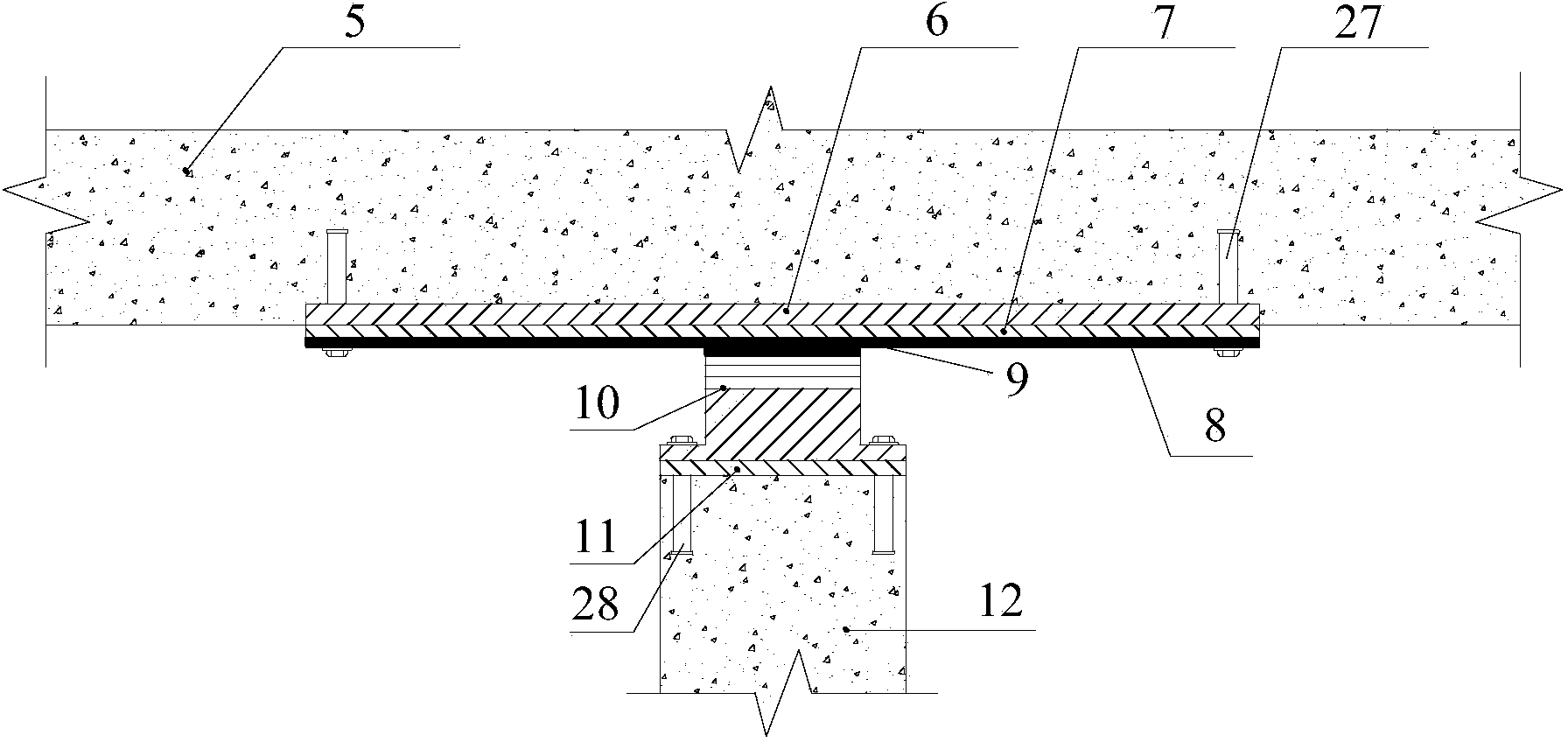

[0026] Such as figure 1 , figure 2 and image 3 As shown, the LNG liquid storage tank shock isolation layer 21 is arranged below the tank body bottom plate 5 for supporting the LNG liquid storage tank 19 tank body 20, including a plurality of reaction walls 4, a plurality of sliding supports 1, a plurality of Laminated rubber bearings 2 and a plurality of viscous dampers 3. The outer shape of the tank bottom plate 5 is circular.

[0027] Such as figure 1 , figure 2 and image 3 As shown, the pile foundation 12 is located below the bottom plate of the tank body 5 , and includes a first-type pile foundation 23 , a second-type pile foundation 24 , a third-type pile foundation 25 and a fourth-type pile foundation 26 . A plurality of pile foundations 23 of the first type are arranged on the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com