Connecting structure and connecting method thereof for shell of liquid reservoir and sleeve

A connection structure and connection method technology, applied in refrigeration and liquefaction, refrigeration components, refrigerators, etc., can solve problems such as sleeve falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

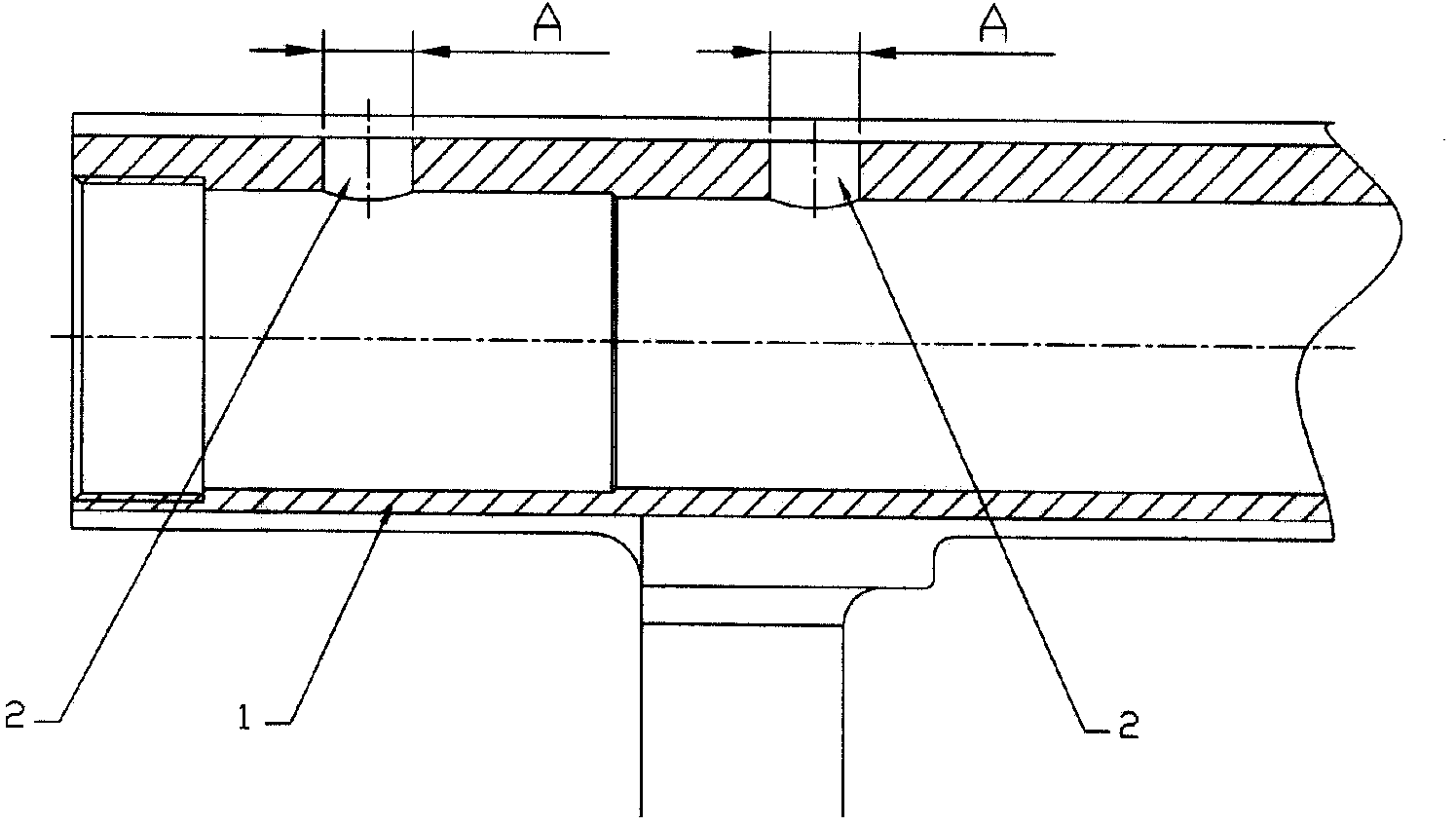

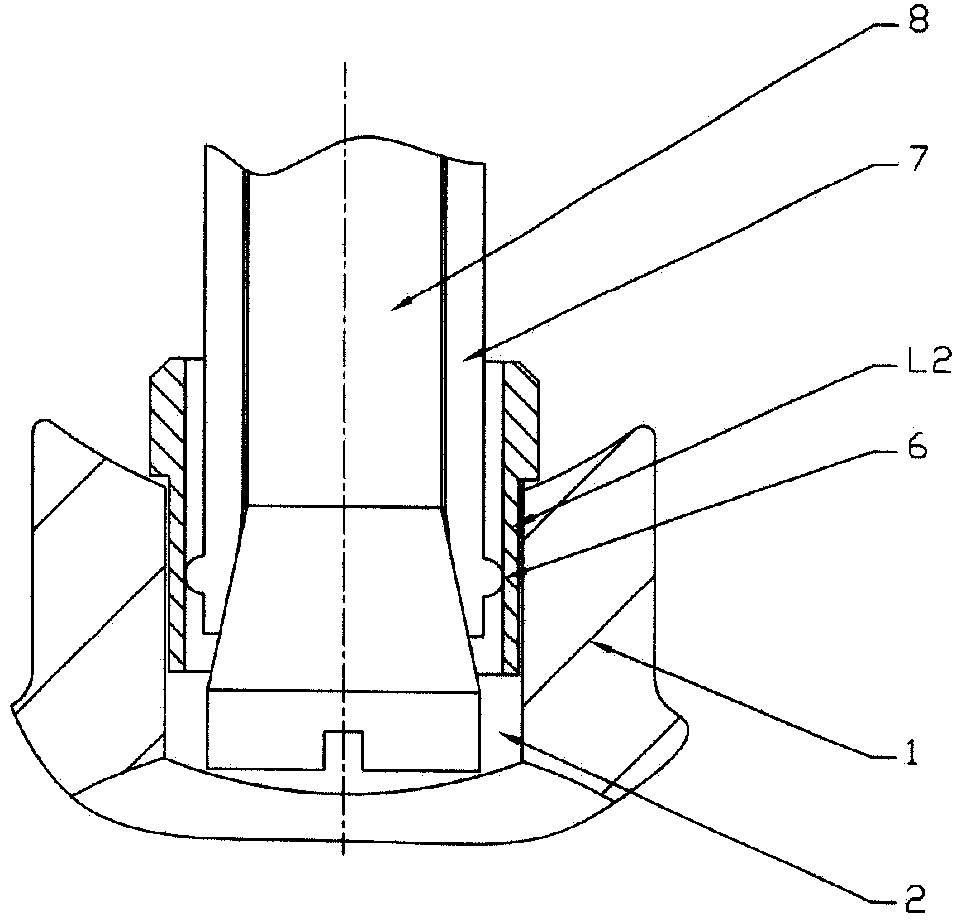

[0017] Accompanying drawing is the connection structure and connection method of liquid storage housing 1 and sleeve, and offers circular through hole on the housing.

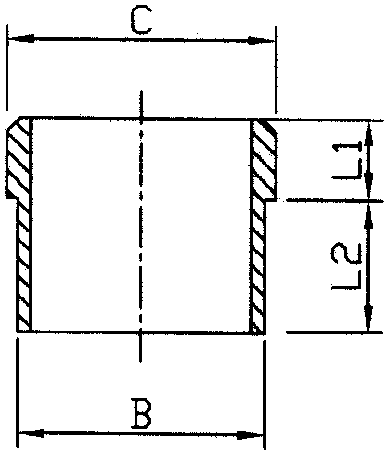

[0018] The connection structure and connection method between the liquid reservoir shell and the sleeve 3 are characterized in that the outer diameter of the sleeve 2 includes a large diameter section and a small diameter section.

[0019] The connection structure and connection method between the housing of the liquid reservoir and the sleeve 2 are characterized in that the diameter of the small-diameter section is smaller than the diameter of the through hole.

[0020] The connecting structure and connecting method of the liquid reservoir shell and the sleeve are characterized in that the small-diameter section is placed in the through hole.

[0021] As a further improvement and supplement to the above connection structure, the present invention also adopts the following additional technical features:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com