Production process of cold silicone liner

A production process and cold spot technology, which is applied in the field of cold spot silicone oil lining production process, can solve the problems that the fabric style cannot be reflected, affect the clothing shape and performance, etc., and achieve high bonding fastness and quality stability, convenient operation, and glue point clear effect

Inactive Publication Date: 2010-11-17

CHANGXING SHIANTE CLOTHING MATERIAL

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a cold spot silicone oil lining production process, which can effectively solve the problem that the existing interlining coating technology requires high temperature heating, which makes the fabric style unable to reflect and affects the clothing shape and performance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] project

[0015] The above is only a specific embodiment of the present invention, but the structural features of the present invention are not limited thereto, any changes or modifications made by those skilled in the art within the field of the present invention are covered by the patent scope of the present invention among.

Peel strength

≥8N / 5×10cm or the base fabric is torn

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

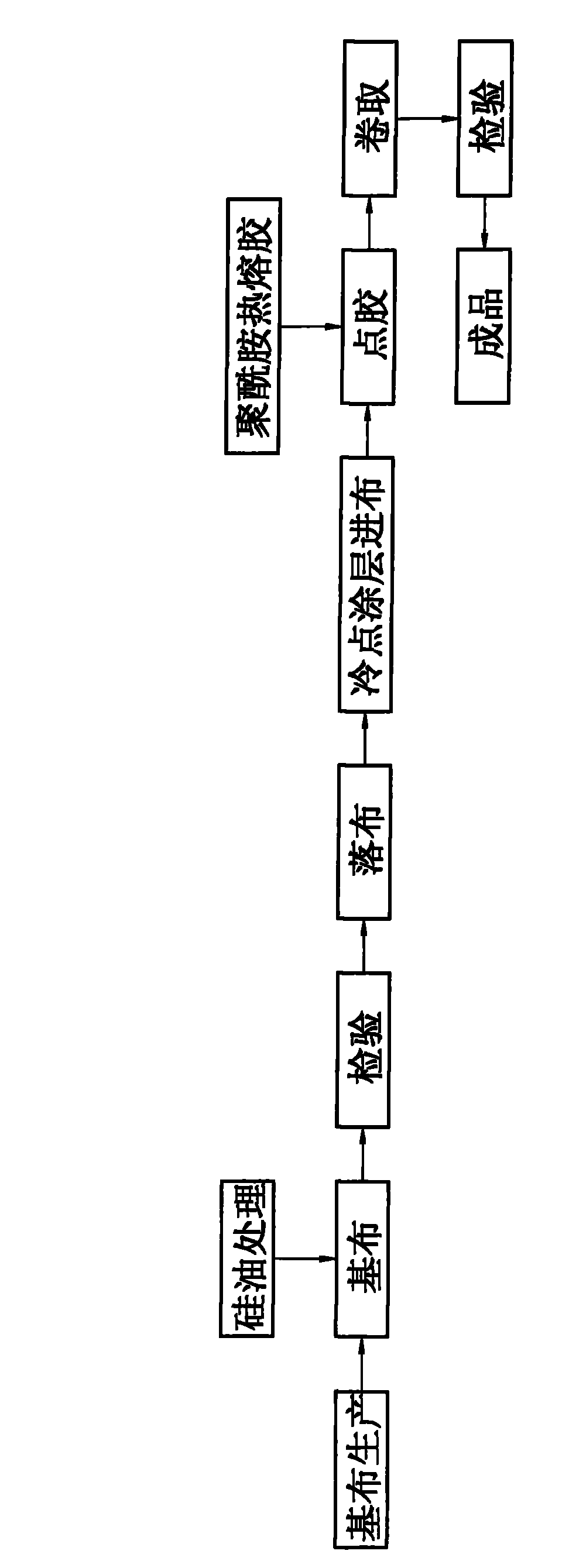

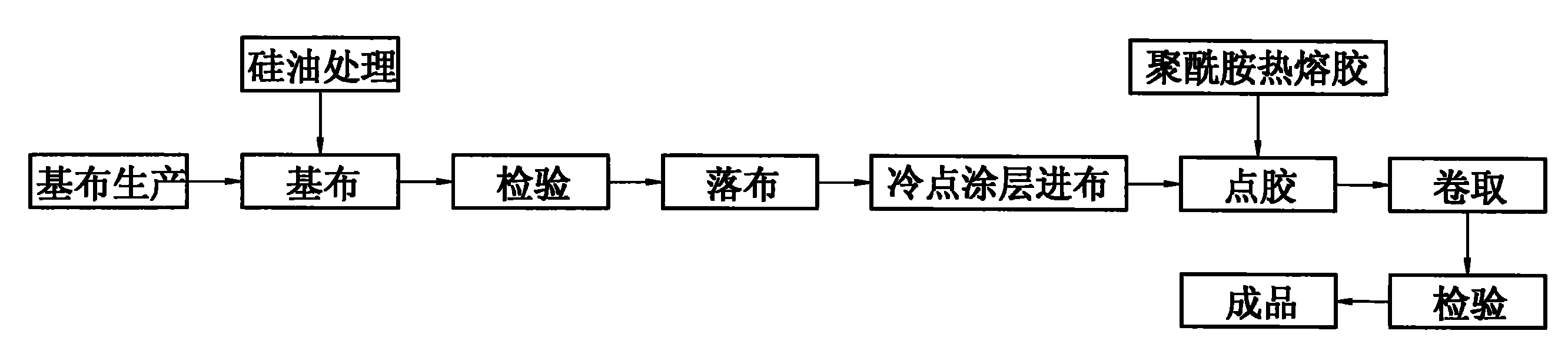

The invention discloses a production process of cold silicone liner, comprising the steps as follows: dipping the produced base cloth, adding with non-ionic microemulsion of amino-modified organic siloxane with 20% fabric weight, the treating temperature being 40 to 50 degrees centigrade, the treatment time being 15 to 20 minutes, then padding, the mangle expression being about 50%, then drying under 120 to 150 degrees centigrade, feeding and dispensing the cold coating; directly painting the polyamide hot-melt adhesive on the base cloth through the cylinder blade; the screen meshes of the cylinder being 140 to 180 screen meshes, the aperture being 0.12 mm, the thickness being 0.02 mm, and the vehicle speed being 30m / min, the environmental temperature in shop being 20 to 30 degrees centigrade, the humidity being 60% to 70%. The invention has the advantages of ensuring the original material and style of the base cloth at maximum without heating; and the products have clear cement and the gum does not fall off, and the bonded fastness and the quality stability are high.

Description

technical field [0001] The invention relates to a production process of an adhesive lining, in particular to a production process of a cold-spot silicone oil lining. Background technique [0002] For interlinings with traditional coating technology (hot melt transfer, powder spreading, powder dots), the base fabric needs to be heated at high temperature during the production process, so that the rubber powder is transferred to the base fabric in a molten state, and then cooled to form a roll. Because the base fabric needs to be heated at high temperature, the style of the fabric itself cannot be reflected, thereby affecting the shape and wearing performance of the garment. Contents of the invention [0003] The purpose of the present invention is to provide a cold-spot silicon oil lining production process, which can effectively solve the problem that the existing interlining coating technology requires high temperature heating, which makes the fabric style unable to refle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A41D27/02D06M15/643D06M15/59

Inventor 严惠莲

Owner CHANGXING SHIANTE CLOTHING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com