Wire mistake-proof plugging tool of wire harness socket

A technology for preventing wrong insertion and sockets, which is applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problems of sockets and wiring harness scrapping, affecting production efficiency, easy to insert wrong hole positions, etc., and achieve a reasonable and ingenious structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

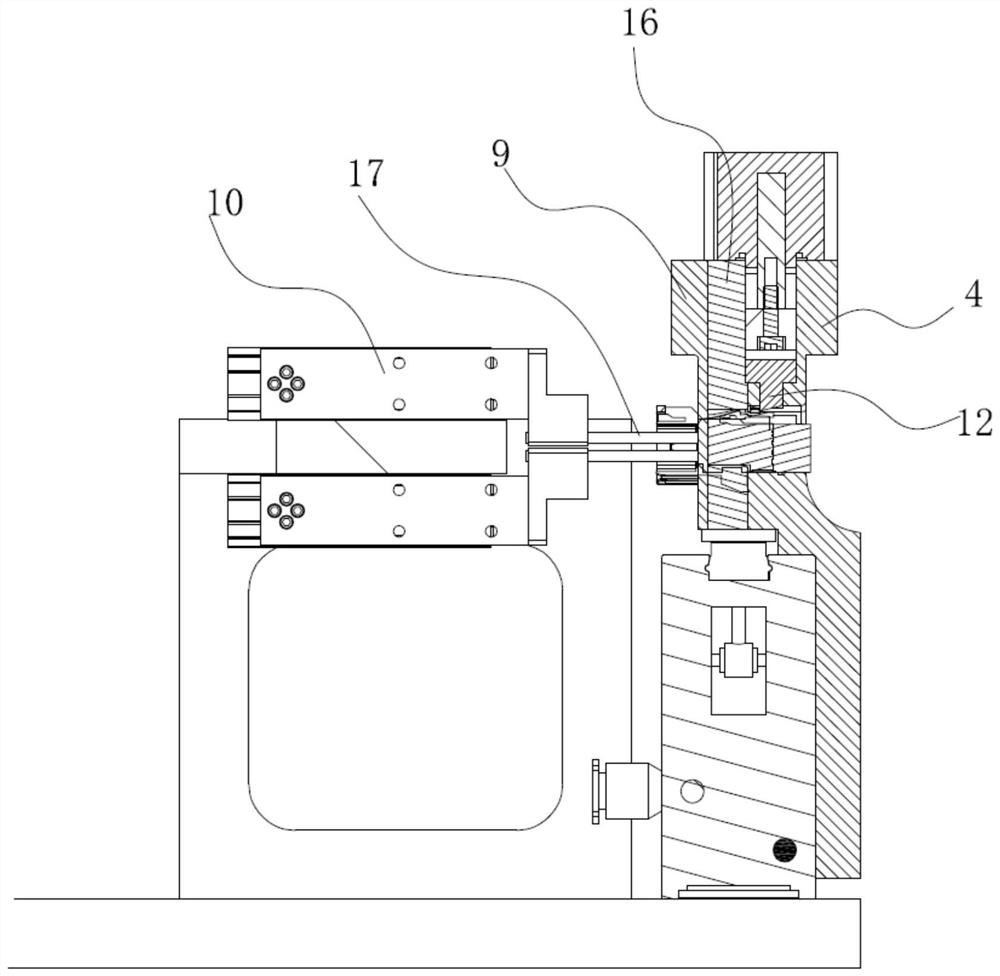

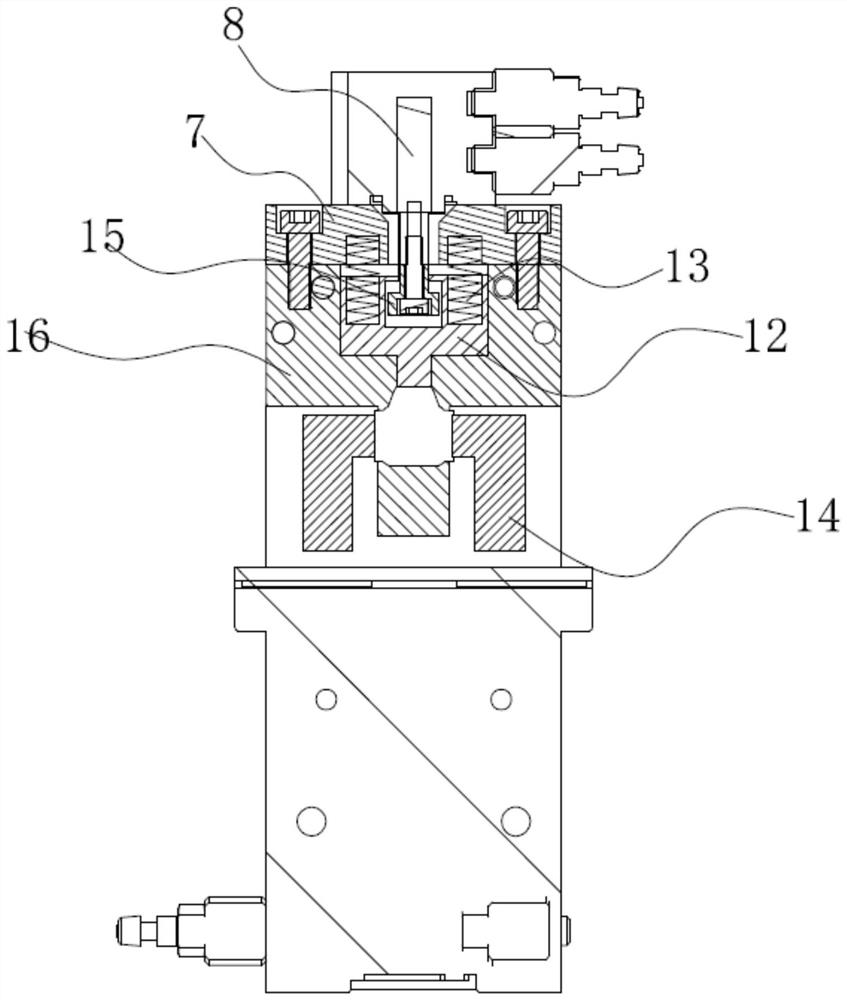

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

[0021] The present invention is provided in order to realize the above-mentioned purpose, to solve the problem of inaccurate detection of the pin depth of automobile wiring harness terminals and low measurement efficiency in the prior art, and the present invention provides the following technical solutions:

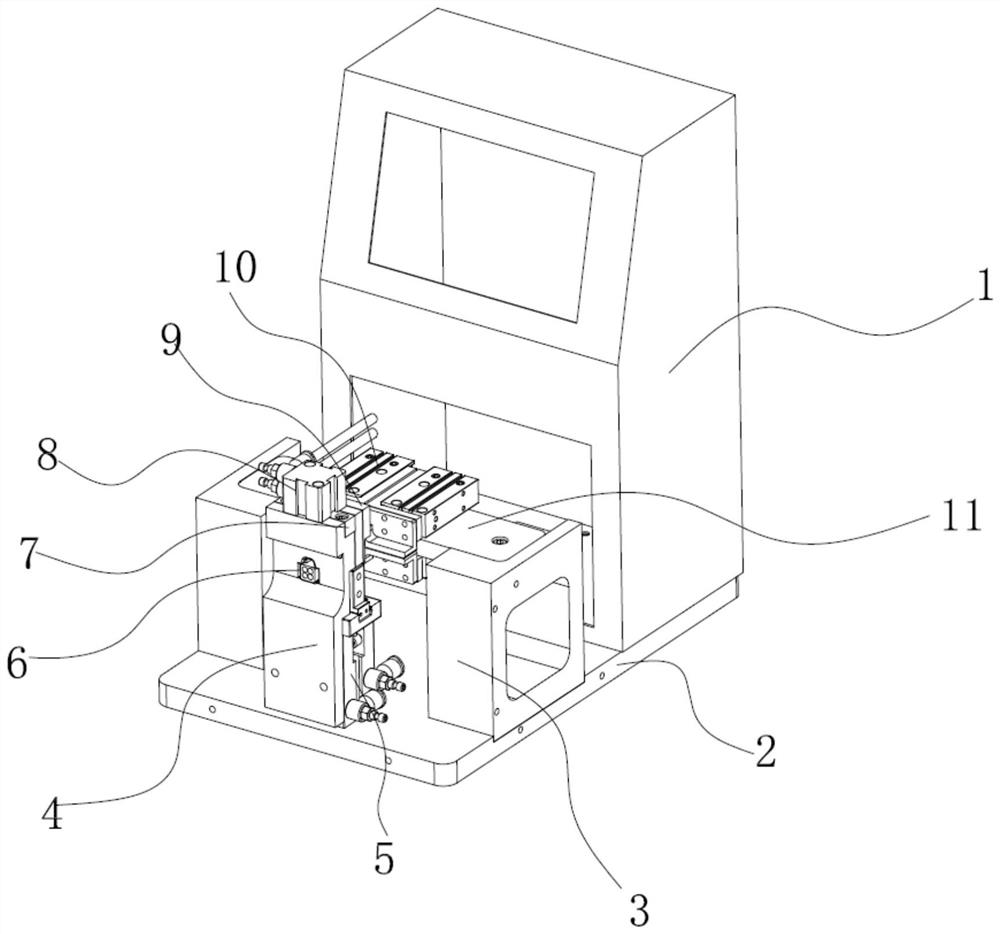

[0022] like Figure 1-4 As shown in the figure, a wire harness socket anti-mating tooling is provided, including:

[0023] The bottom plate 2, the console 1 is installed on the rear side of the upper end of the bottom plate 2, the bottom plate 2 is in the shape of a flat plate, the console 1 is provided with a display screen, and the front end of the console 1 is provided with control buttons;

[0024] Bracket 3, the bracket 3 is installed on the bottom plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com