Variable load fatigue testing machine for small deformation parts

A fatigue testing machine and small deformation technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve problems such as failure to meet ground anchor mechanics and deformation requirements, damage and other problems, and achieve the requirements of reducing manufacturing accuracy and eliminating The effect of itinerary matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

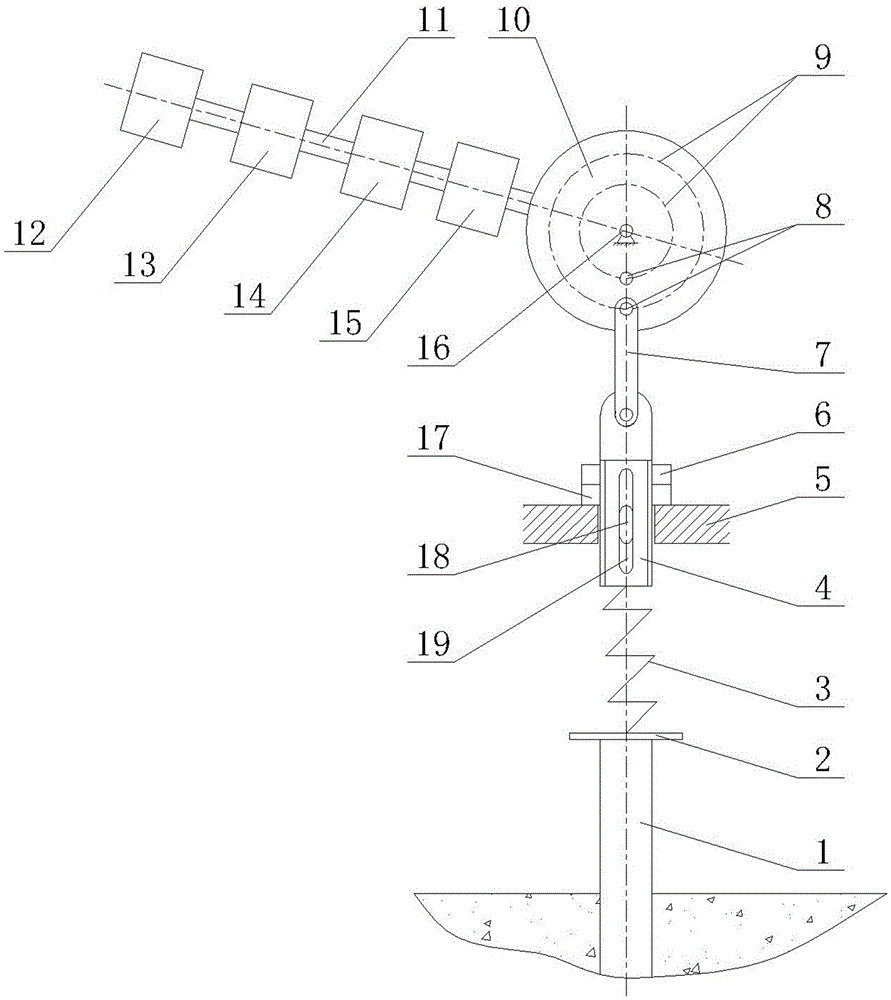

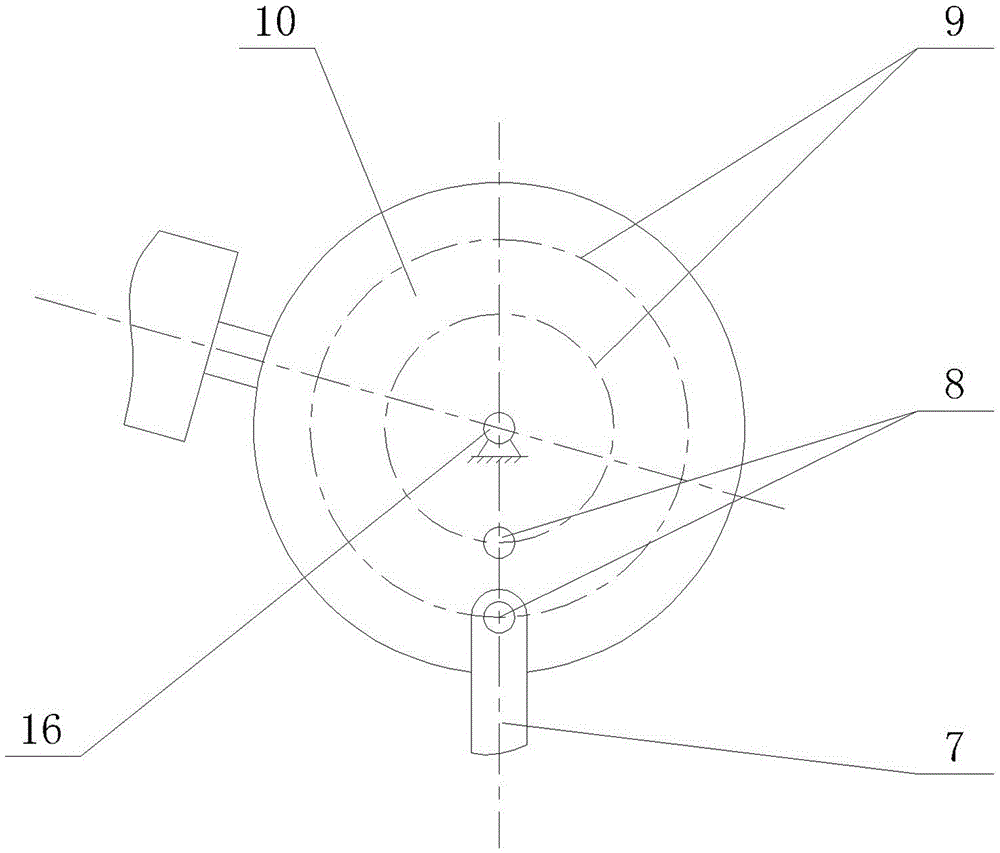

[0026] like figure 1 , figure 2 Shown is one of the embodiments of the present invention. In this embodiment, the variable load fatigue testing machine used for small deformation parts is provided with a driving mechanism, and the driving mechanism drives the rotating disk 10 to rotate. The rotation center of the rotating disk 10 and itself The geometric centers of are coincident or not coincident, such as figure 1 The coincidence method is adopted in the method; the ground anchor 1 to be tested is fixed on the foundation, and the rotating disk 10 is connected to the ground anchor 1 to be tested through the connecting rod 7, the sliding rod 4, and the spring 3 connected in sequence, and the ground anchor 1 is periodically applied. Varying tension; a force sensor 2 is set between the tested ground anchor 1 and the spring 3 to detect the tension value of the ground anchor 1.

[0027] Since the spring 3 is deformable, the influence of small deformations of the ground anchor 1 ...

Embodiment 2

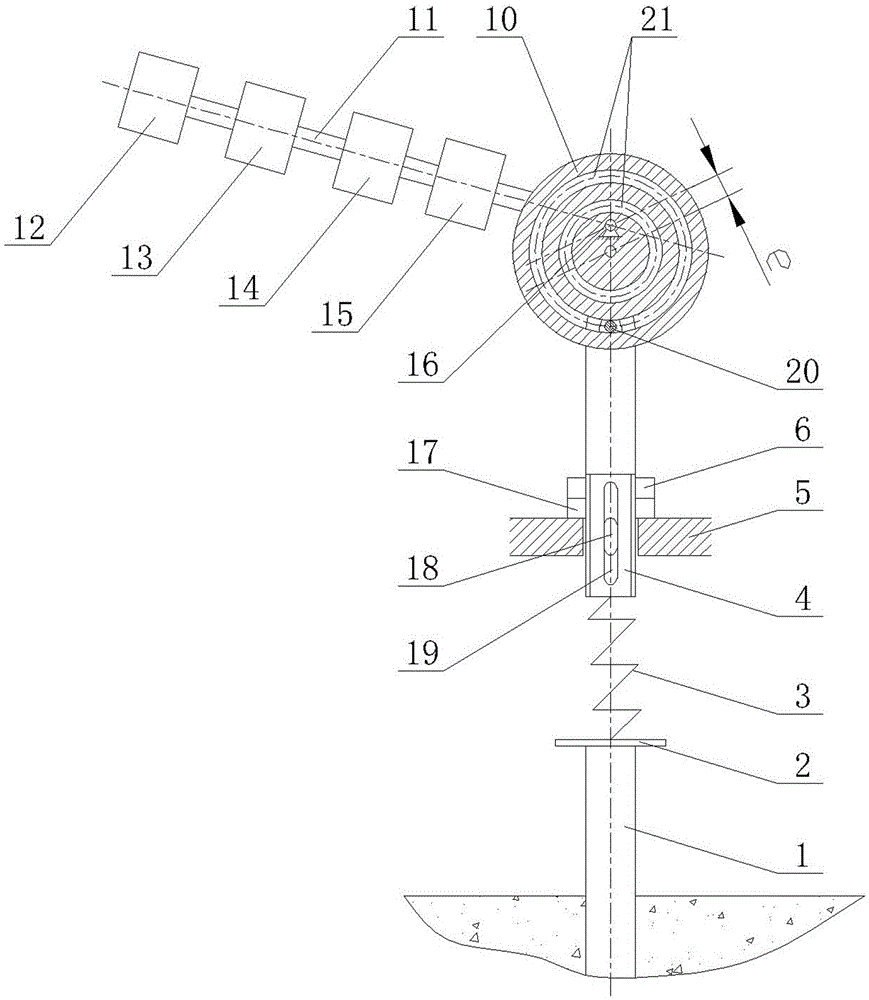

[0038] like image 3 , Figure 4 Shown is the second embodiment of the present invention, and the difference from embodiment 1 is that in this embodiment, the rotation center 16 of the rotating disk 10 does not coincide with its own geometric center 22, the rotating disk 10 is an eccentric structure, and the eccentric distance e, when the rotary disk 10 rotates once, the elongation of the spring 3 is x=2*e.

[0039] In this embodiment, the rotating disk 10 is provided with circular chute 21 with different diameters, and the pin shaft is connected to the connecting rod in the chute 21, and the minimum tension and maximum tension generated by the fatigue testing machine are set through different chute. ; The connecting rod and the sliding rod are integrally formed, forming image 3 The slide bar 4 in the slide bar 4 is provided with a guiding support seat 5, and the support seat 5 is provided with a guide hole, and the slide bar 4 moves up and down along the guide hole, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com