A detonator drying device

A technology for drying device and priming charge, which is applied to explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of long drying time of vacuum dryer, low drying quality of priming charge, and low production process efficiency, and achieves the drying level. Fully qualified, shortened drying time, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

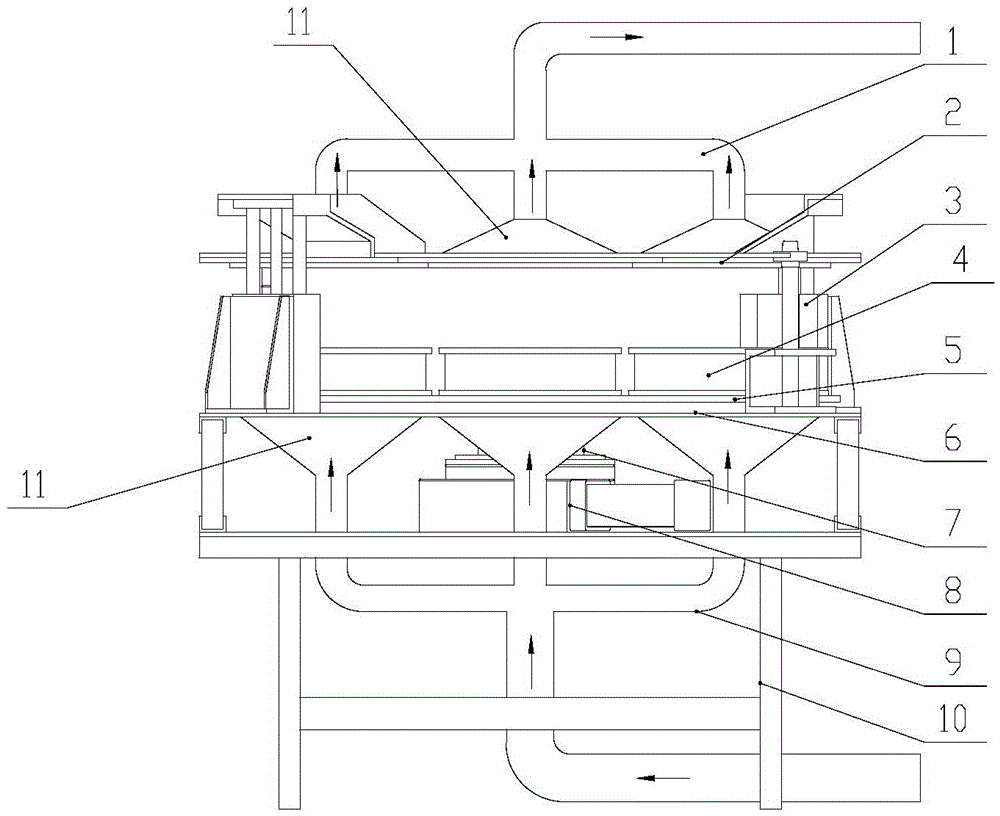

[0033] A kind of detonator drying device, see details figure 1 , Including the first pipeline 1, the upwind hood fixing plate 2, the first cylinder 3, the medicine box 4, the medicine box tray 5, the downwind hood fixing plate 6, the second cylinder 7, the second pipeline 9, the base 10 and the controller , Wherein the second pipeline 9 is an inlet hot air pipeline, and the first pipeline 1 is an outlet pipeline.

[0034] The medicine box tray 5 is arranged on the base 10 by a rotary indexing cylinder 8, the medicine box tray 5 is arranged on the top of the rotary indexing cylinder 8, and N medicine boxes 4 are provided on the medicine box tray 5 , N is greater than or equal to 2, preferably the medicine box 4 is evenly distributed on the medicine box tray 5 along the circumference, N is 4-12, the medicine box tray realizes indexing rotation with the rotation of the rotary indexing cylinder, which is convenient for the robot to remove the medicine The pill box is placed or remove...

Embodiment 2

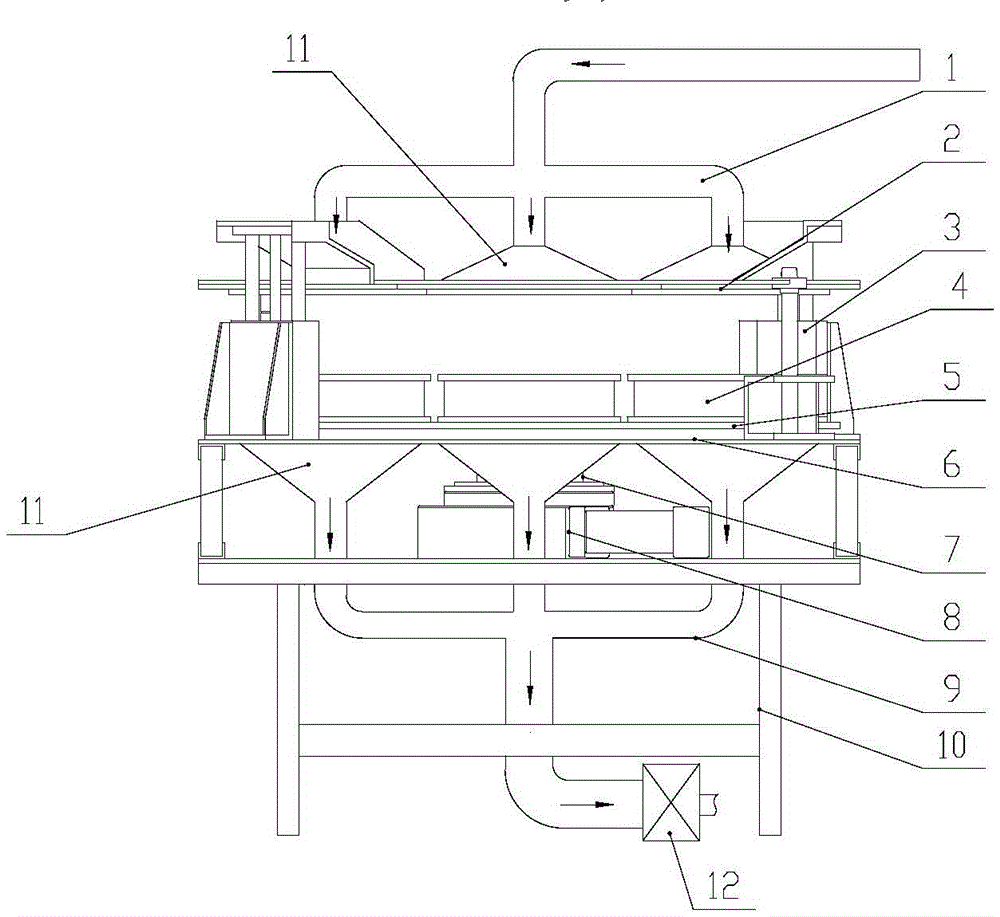

[0046] The difference between this embodiment and embodiment 1 is that the second pipeline 9 is an air outlet pipeline connected to the vacuum pump 12, and the first pipeline 1 is an inlet hot air pipeline. For details, see figure 2 , Its working principle is as follows:

[0047] Before drying, the second cylinder 7 controls the lower air hood fixing plate 6 to be located at the lowest position, and the first cylinder 3 controls the upper air hood fixing plate 2 to be located at the uppermost position; the rotary indexing cylinder 8 drives the medicine box tray to rotate by 5 degrees, and the manipulator In the previous process, the pill boxes 4 containing the wet initiating charge are placed on the pill box tray 5 in turn. When the pill box tray 5 is filled with the pill boxes 4, the first air cylinder 3 controls the upper air hood fixing plate 2 to move vertically downward , The second cylinder 7 controls the downwind hood fixing plate 6 to move vertically upwards until the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com