Name plate bonding device and bonding method and its application in automobile parts

A technology for bonding devices and nameplates, applied in the direction of bonding methods, adhesives, etc., can solve problems such as incorrect placement, low efficiency, eye-catching, delicate, and poor aesthetics, and achieve high efficiency and consistency in bonding operations Good, show eye-catching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

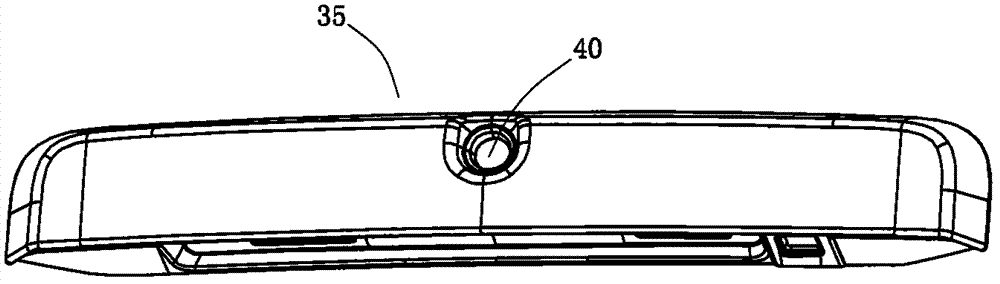

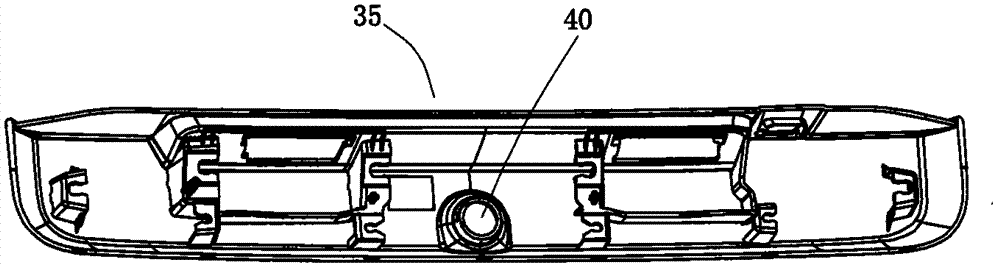

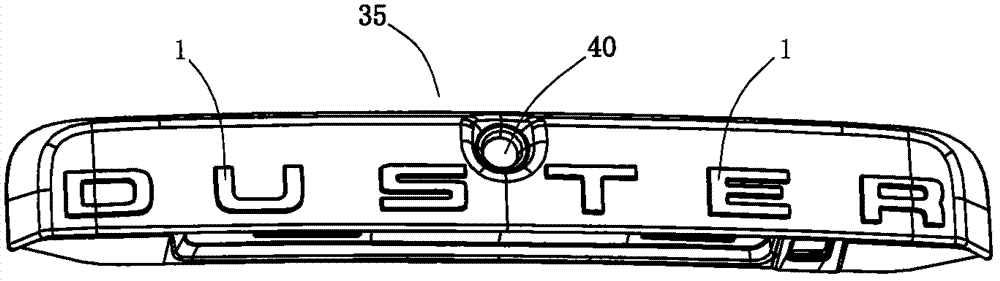

[0037] Below to Figure 1 to Figure 3 The tailgate handle shown as workpiece 35 illustrates a specific embodiment of the invention.

[0038] The tailgate handle is located at the opening of the trunk of the car, and there is a hole 40 in the middle, which is used to install the door switch, and is also used as the place where the nameplate is glued, and the trademark composed of 6 letters "DUSTER" is glued; the tailgate The door handle is a plastic injection molded part. In order to make the nameplate eye-catching, exquisite and beautiful, the 6 nameplates 1 are made separately, which can be metal parts or plastic plating parts; among them, the nameplate 1 of the letter S is as Figure 7 , Figure 8 Shown; Keep proper spacing after bonding, such as image 3 shown.

[0039] Name plate adhesive sheet 16 such as Figure 4As shown, it is actually a double-sided adhesive tape tailored according to the shape and size of each letter. It is recommended to use high-quality adhesive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com