Movable lifting material rack

A technology for moving lifting racks and lifting rods, which is applied in the direction of lifting frames and lifting devices, which can solve the problems of high cost, high physical requirements for operators, and increased labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

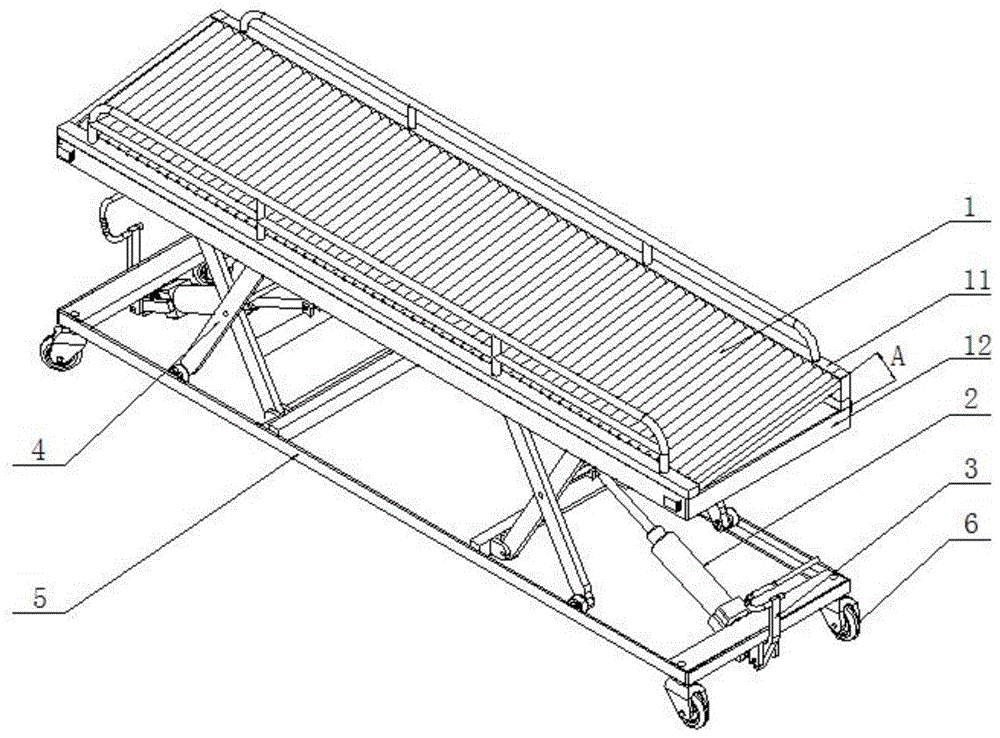

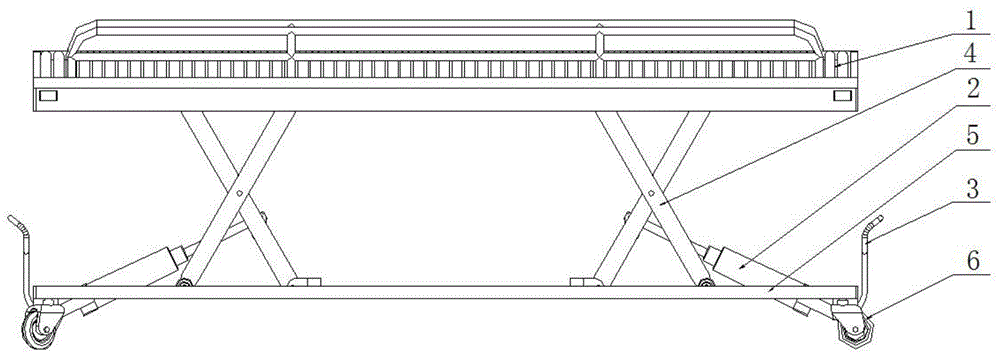

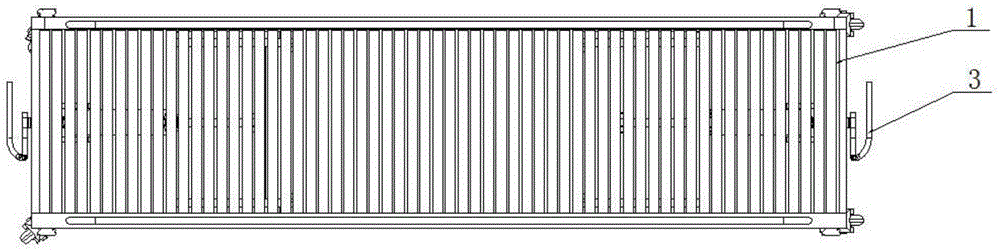

[0020] This embodiment provides a mobile lifting rack with a structure such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a pipe fitting placement area 1, a foot-operated hydraulic cylinder 2, a pedal 3, a lifting rod 4, a bottom frame 5, and a universal wheel 6. The pipe fitting placement area 1 includes a pipe fitting placement frame 11 and a placement base 12, and the pipe fitting placement frame 11 and placing base 12 are rectangular structures identical in shape, and pipe fittings placing frame 11 two long sides symmetrical vertical pipe fittings placing frame 11 is provided with two guardrails, and placing base 12 long edge inner side is provided with chute, and pipe fittings placing frame 11 and placing base 12 each has a long side connected to each other, and the other long side is separated at a certain angle, and the edge of the separated long side is arranged horizontally with a long rod and welded for support;

[0021] Four universal wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com