Immersion-type heat exchanger

A technology of immersion heat exchangers and heat exchange tubes, which is applied in the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as fast heat dissipation, poor heat preservation effect, and uneven heat transfer, and achieve Increased heat transfer rate and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

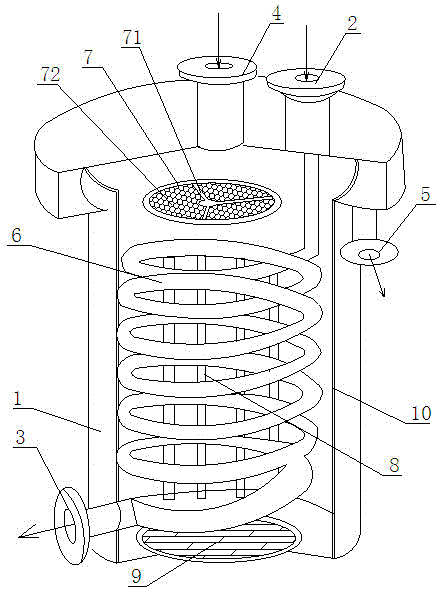

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0013] Such as figure 1 As shown, an immersion heat exchanger of the present invention includes a shell 1, a fluid A inlet 2 and a fluid B inlet 4 are opened on the top of the shell 1, a fluid A outlet 3 is opened on the bottom of the shell 1, and the side of the shell 1 There is a fluid B outlet 5 on the upper part, and a heat exchange tube 6 is arranged inside the shell 1. The upper end of the heat exchange tube 6 communicates with the fluid A inlet 2, the lower end of the heat exchange tube 6 communicates with the fluid A outlet 3, and the fluid A inlet 2 places The housing 1 is provided with a fluid dispersion plate 7, the spiral passage of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap