Automatic cable coupler

An automatic cable and connector technology, applied in the direction of clamping/spring connection, etc., can solve problems such as easy loosening and falling off of the tape, short service life, and affecting circuit stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

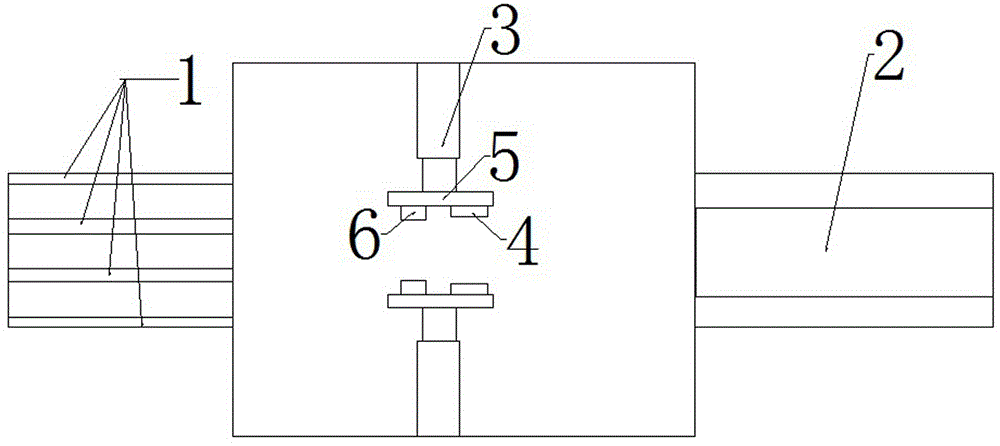

[0017] An automatic cable connector, comprising: a branch channel 1 with a fixed position and containing branch cables, a main channel 2 fixed to the branch channel 1 and containing the main cable, placed in the main channel 2 and automatically firmly connecting the branch cables The connection assembly of the synthetic main cable, the connection assembly includes: the electronic telescopic rod 3 placed on both sides of the inner wall of the main channel 2, the pressing piece 5 connected to the electronic telescopic rod 3, placed under the pressing piece 5 and limiting the main cable The limiting part is placed under the pressure sheet 5 and is positioned at the conductive sheet 4 next to the limiting part; the conductive sheet 4 is a conductive metal sheet, and as a preferred copper sheet, the electronic telescopic rod 3 is preferably mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com