Riser weak link

A joint, riser section technology, used in drill pipe, casing, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

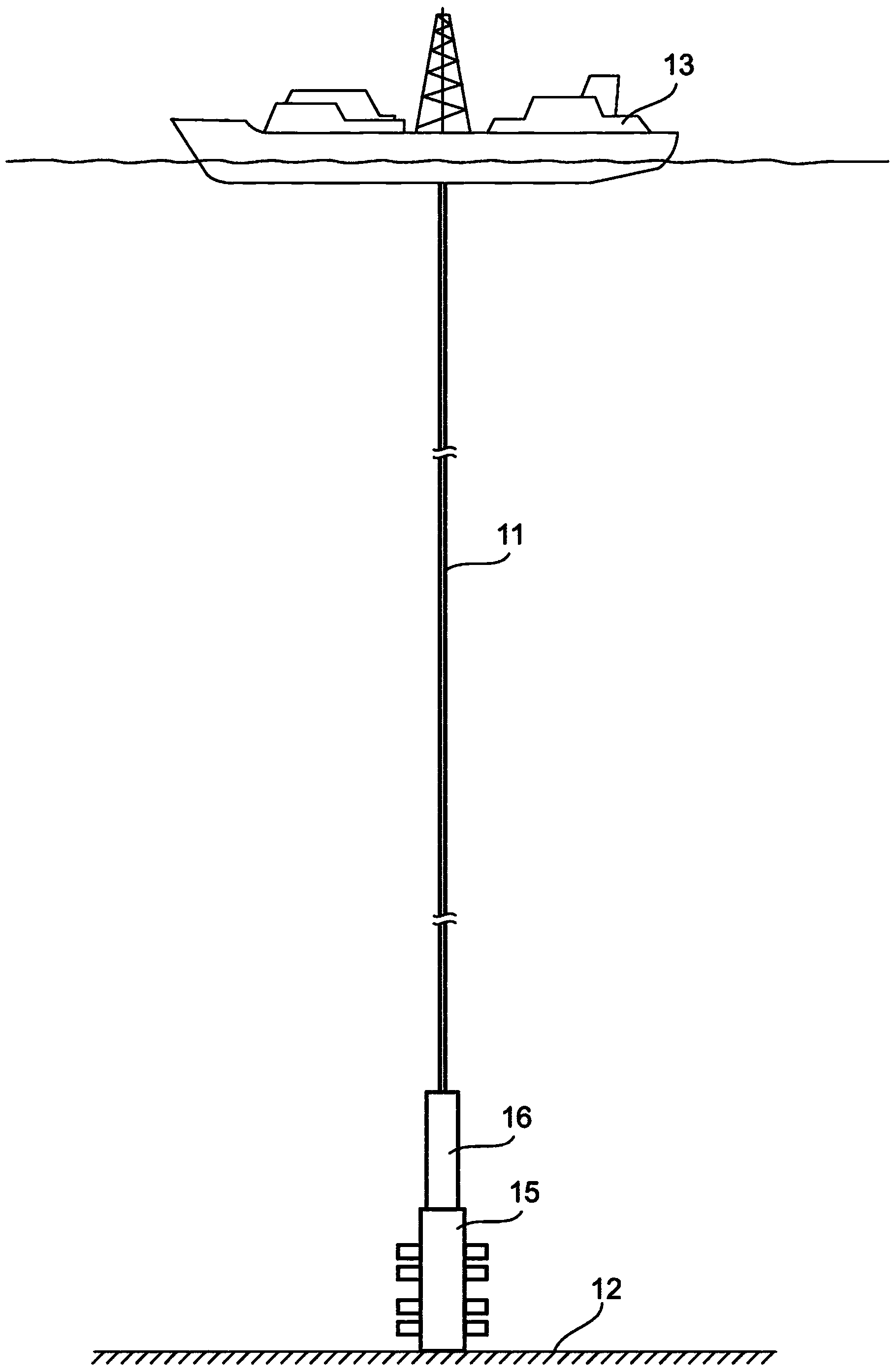

[0070] figure 1 A schematic view of a riser provided with a weak link according to the invention is shown. Risers 11 are typically used to connect oil and gas wells on the sea floor 12 to floating installations or vessels 13 on the surface 14, such as oil rigs or ships. On the seabed 12 the riser is connected to a subsea test tree 15 via a weak link 16 according to the invention. The standpipe 11 consists of pipe sections and is very heavy. Consequently, the surface vessel 13 must exert a tensile force on the riser 11 to prevent it from collapsing under its own weight. However, in certain sea conditions, such as when the vessel is moving, the applied tensile force will fluctuate. When the riser is fixed at its lower end to the subsea test tree 15 on the seabed and at its upper end to the floating installation or vessel 13 by means of tensioners, the movements of the installation caused by wind, wave and tidal action must be accommodated. Therefore, a motion compensating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com