A door body foaming equipment

A foaming equipment and door body technology, applied in the field of door body foaming equipment, can solve the problems of complex mechanical structure, large equipment footprint, high manufacturing and maintenance costs, and achieve strong process adaptability, small footprint, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

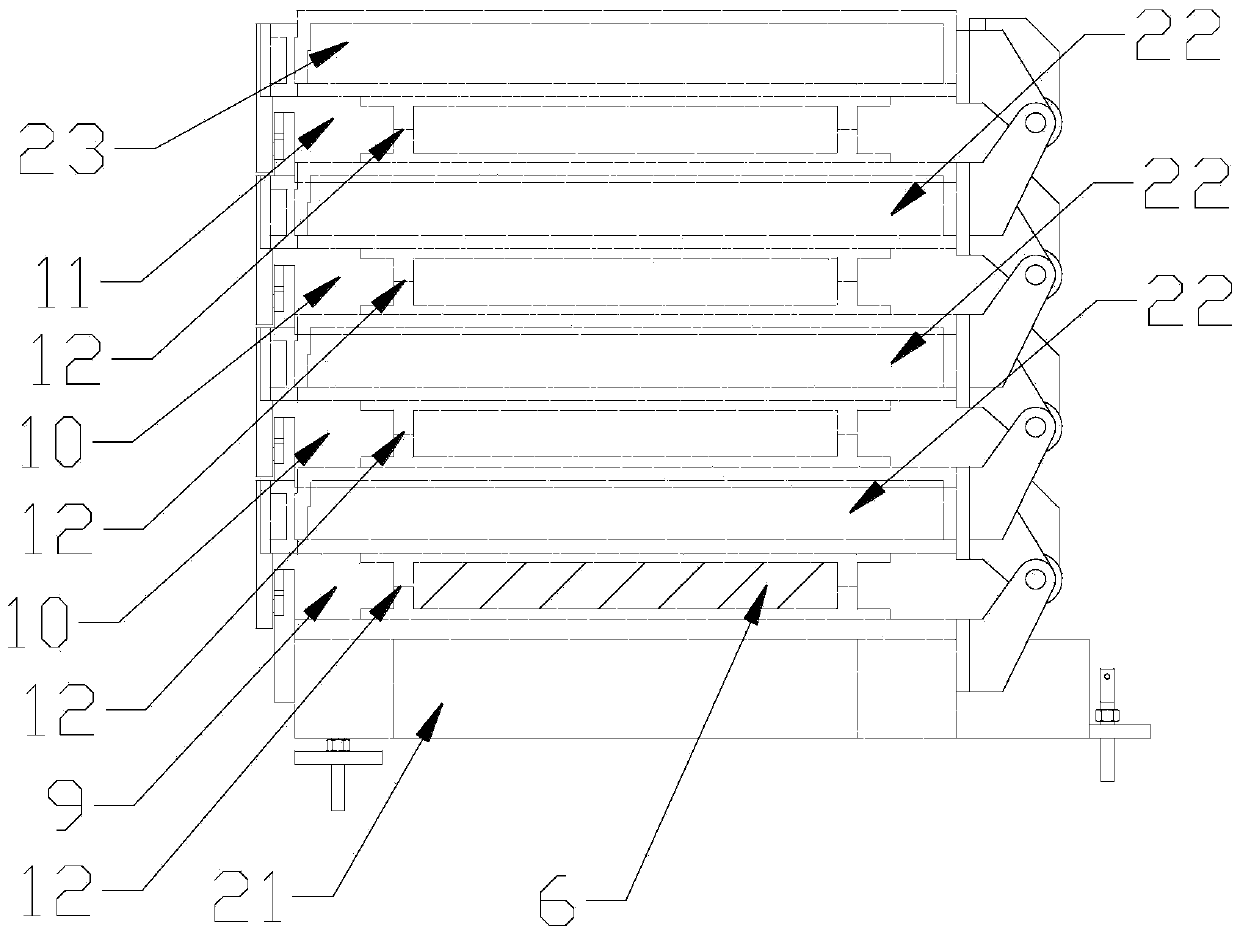

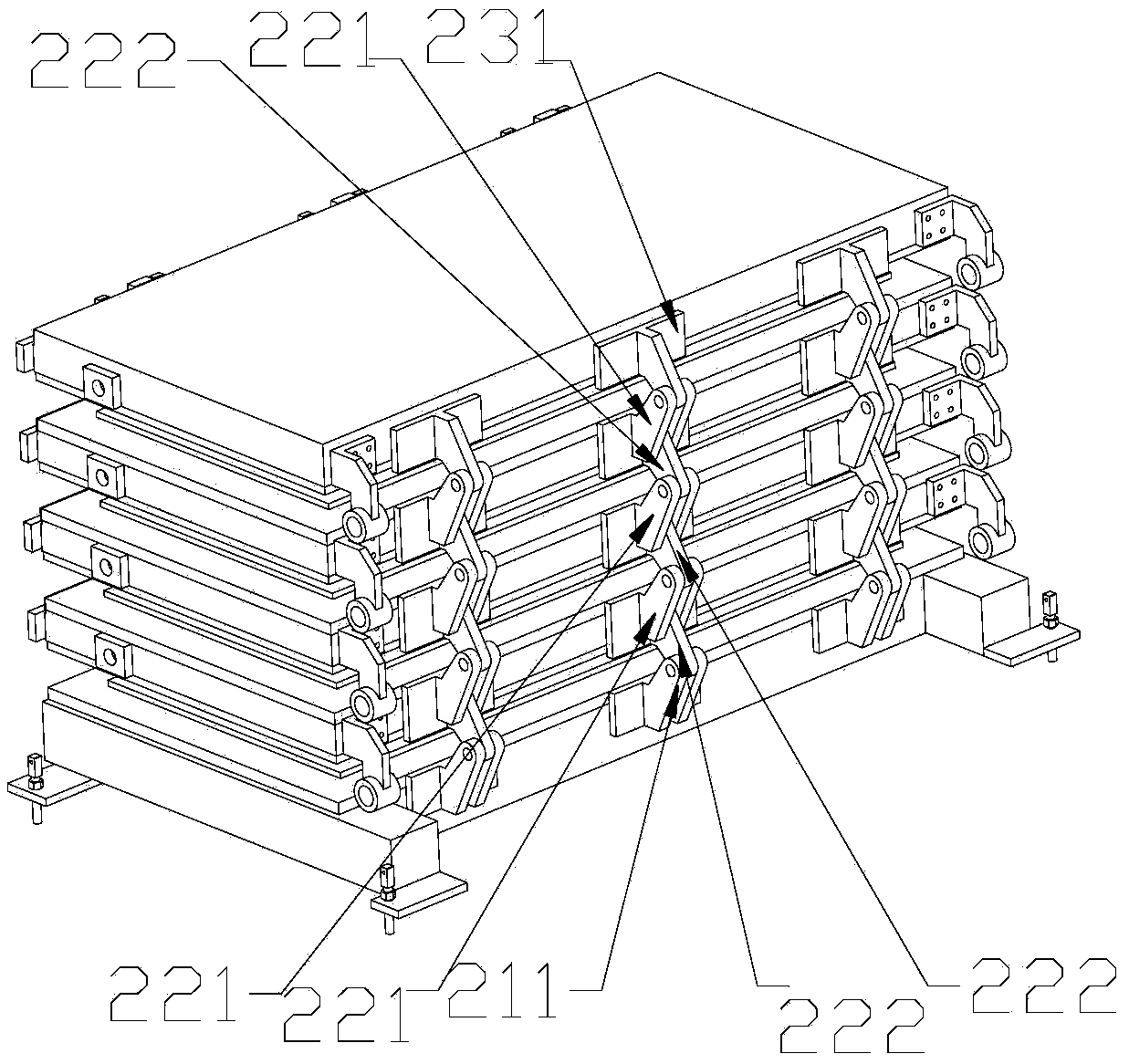

[0033] In this embodiment, the number of the intermediate layer templates is 3 (that is, the stacked fixture consisting of four clamps consisting of the lowest template, three intermediate templates and the lowest template is taken as an example).

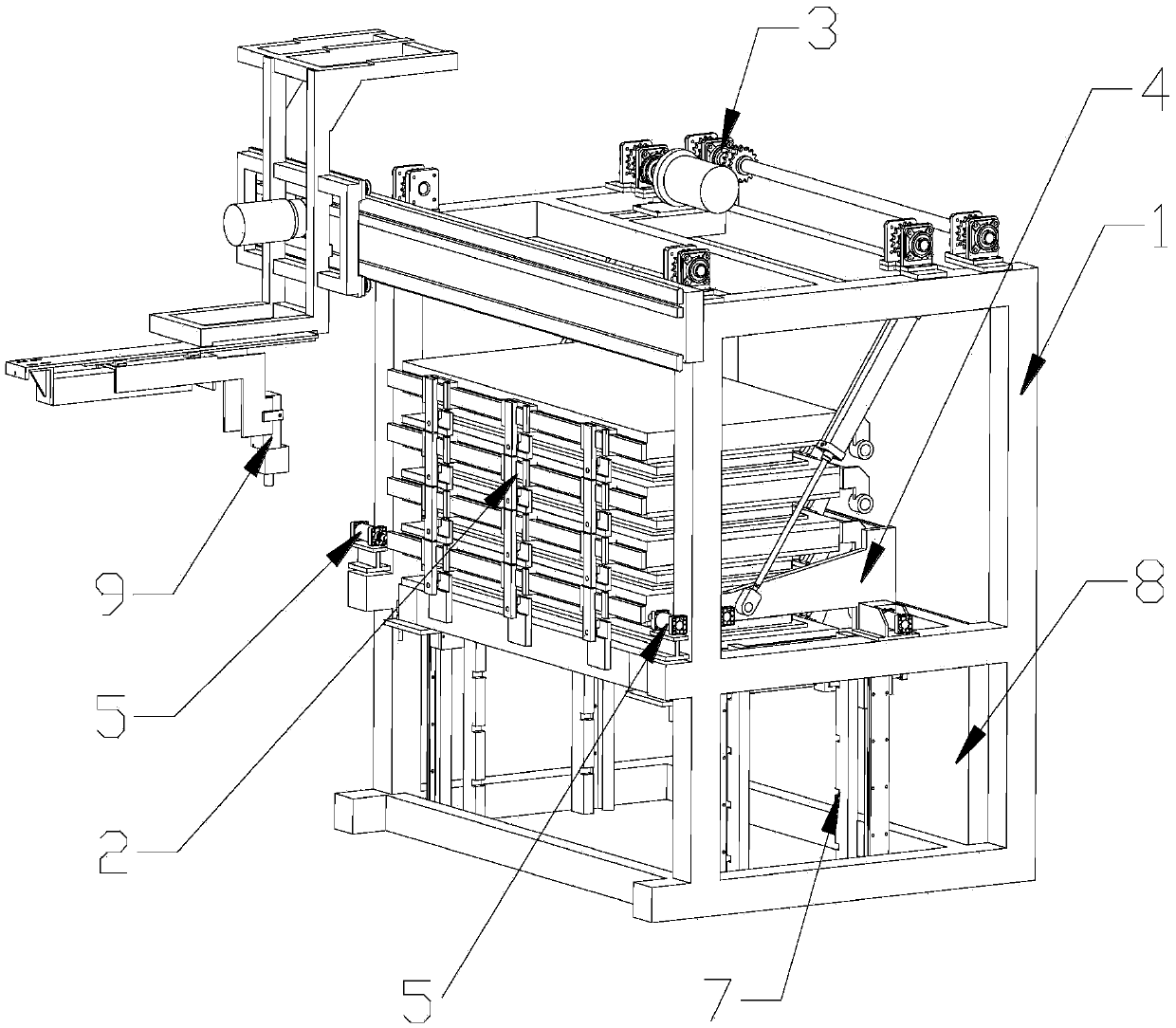

[0034] refer to Figure 1 to Figure 9 , a door body foaming equipment, including a frame 1 and a stacked clamp 2 arranged on the frame 1, a lifting mechanism 3, a rotary mold opening mechanism 4, a mold opening and locking mechanism 5, and a filling system 8, the The lifting mechanism 3, the rotary mold opening mechanism 4, the mold opening and locking mechanism 5 and the filling system 8 are controlled by a controller;

[0035] The stacked fixture is composed of the lowermost template 21, three intermediate templates 22 and the uppermost template 23 sequentially stacked from bottom to top. The lower end surface of the middle layer template 22 and the lower end surface of the upper layer of the middle layer template are jointly en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com