Spatial arrangement system for embedded prefabricated house

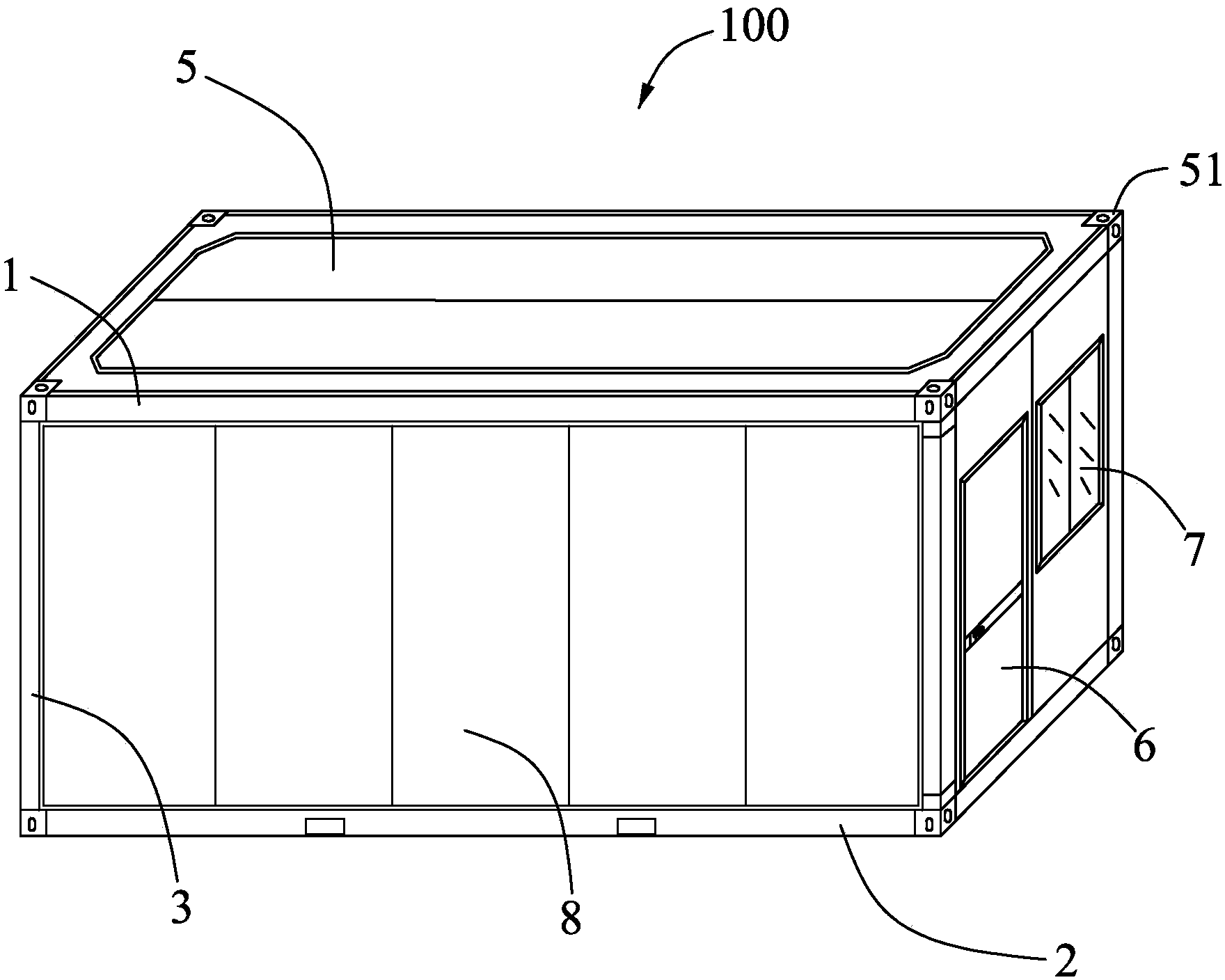

A prefabricated house, embedded technology, applied in the direction of architecture, building structure, etc., can solve the problems of complex embedded structure, and achieve the effect of simple embedded structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

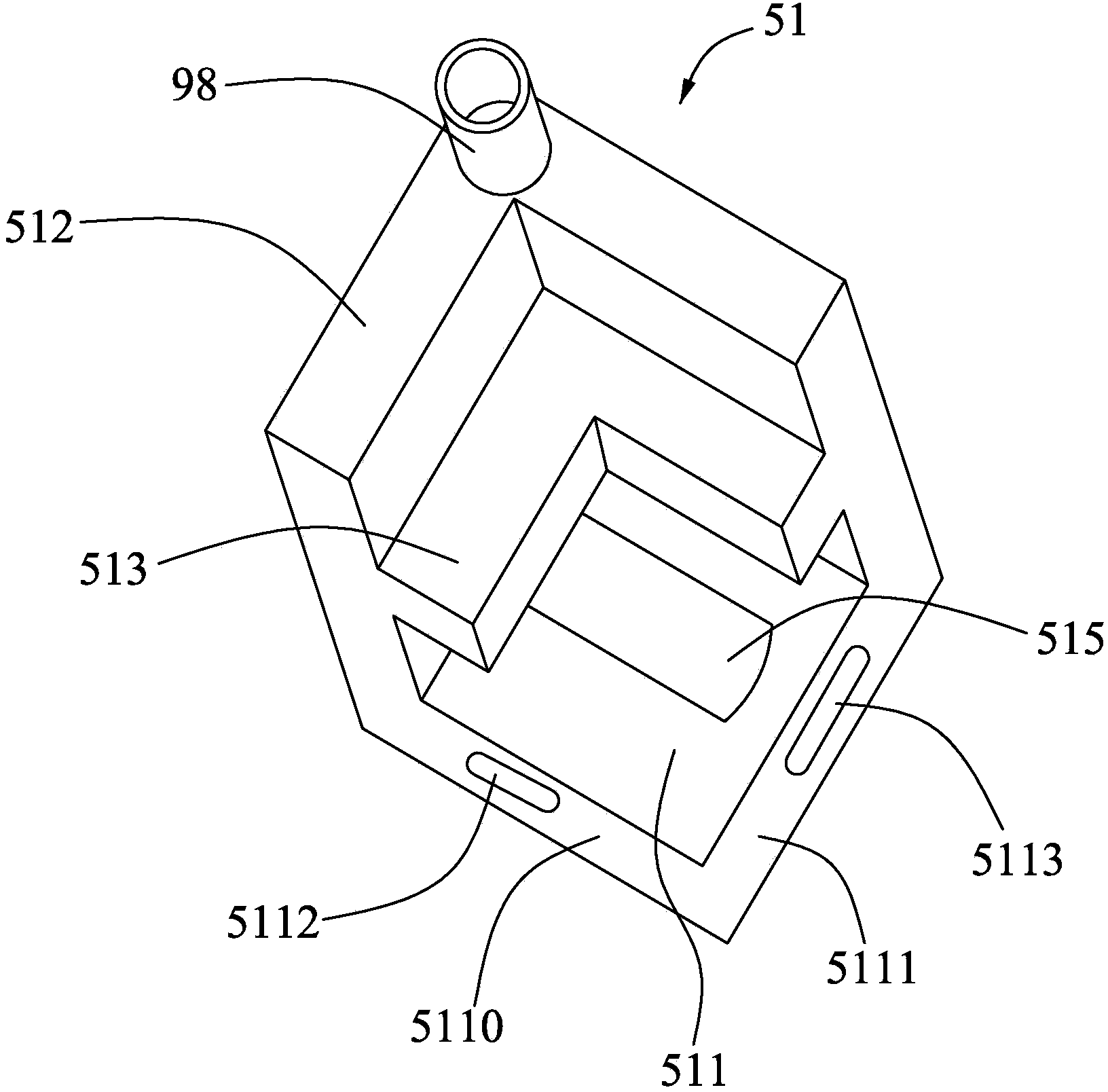

[0029] The spatial layout system 100 of the embedded prefabricated house further includes a top corner piece 51 arranged on the top of the connecting corner post 3 , and the top corner piece 51 fixedly connects the top beam 1 and the connecting corner post 3 together. The top corner piece 51 includes a square bottom base 511 , an L-shaped outer connecting portion 512 extending upward from the bottom base 511 , and an inner connecting portion 512 located above the bottom base 511 and extending inward from the inner side of the outer connecting portion 511 . Connecting part 513 . The top corner piece 51 also includes a drain pipe 98 extending upward from the outer connecting portion 512 . The inner connecting portion 513 is also L-shaped. The base portion 511 has a first side wall 5110 and a second side wall 5111 adjacently arranged, and the base portion 511 is also provided with a first through hole 5112 penetrating the first side wall 5110 and a hole penetrating the second si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com