Deepwater petroleum drilling casing pipe joint rotation preventing structure

A technology for drilling casing and oil, which is applied in the field of structural improvement and design of oil drilling tools, which can solve problems such as poor reliability of anti-rotation, and achieve the effects of convenient installation, easy manufacture, and simple embedded structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

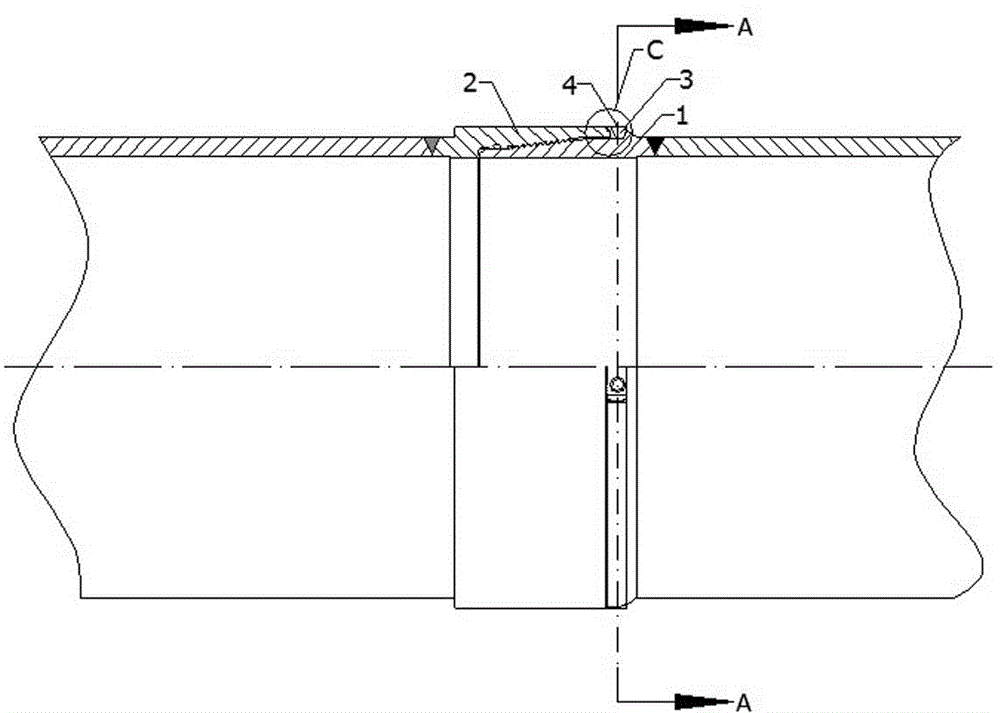

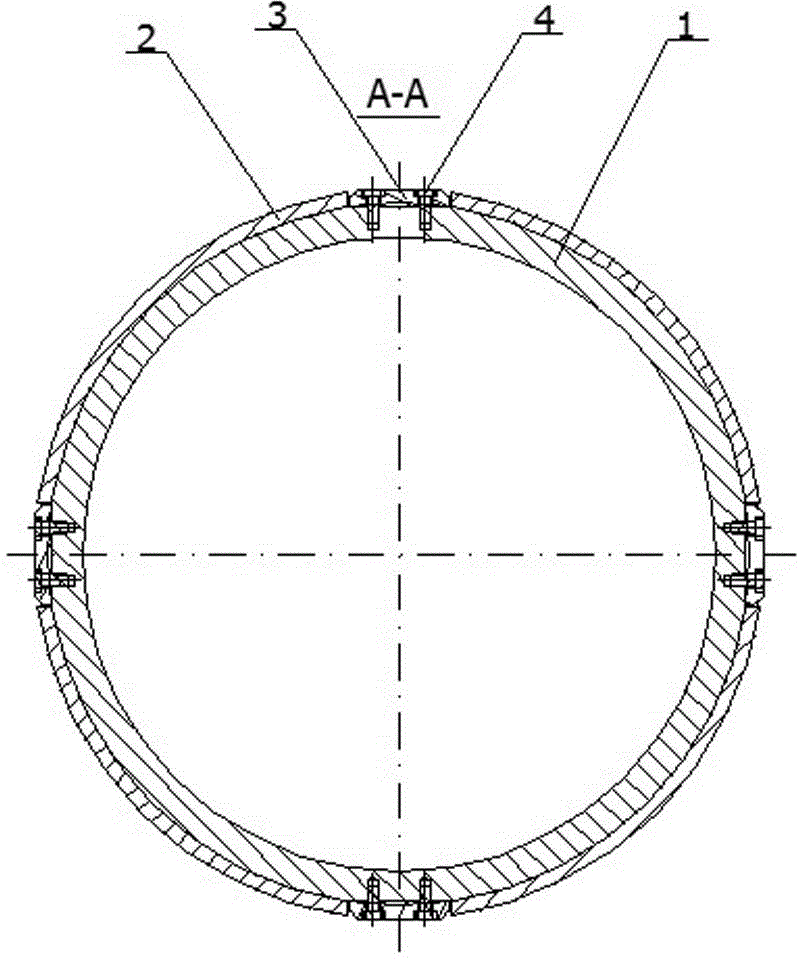

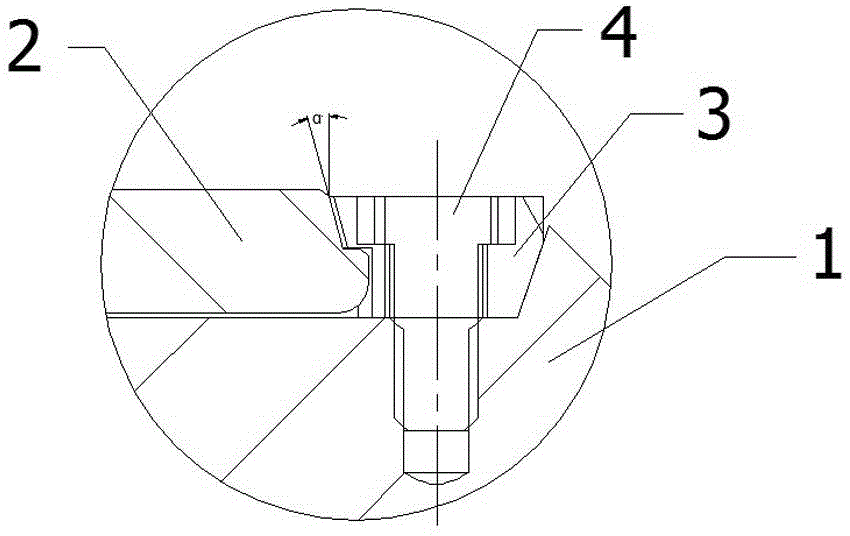

[0018] figure 1 The anti-rotation structure of the deep-sea oil drilling casing joint shown is composed of a threaded male joint 1, a threaded female joint 2, a wedge 3 and a screw 4. The threaded male joint 1 and the threaded female joint 2 are a pair of matching tapered threaded joints, which are respectively connected to the two ends of the casing. This structure is convenient for one threaded male joint 1 to be screwed into the other threaded female joint 2 to form a joint structure. The wedge 3 is a member for anti-rotation, such as Figure 4 The shown wedge 3 is shaped like a rectangular block. Such as image 3 As shown, the side of the wedge 3 facing the threaded female joint 2 is provided with a dislocation shoulder, and the side of the upper shoulder facing outward is an inclined plane, and straight teeth are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com