Composite lead-acid storage battery negative grid

A composite lead-acid battery technology, which is applied in the field of lead-acid battery negative grid and lead-acid battery grid, to achieve the effects of simple embedded structure, improved service life and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

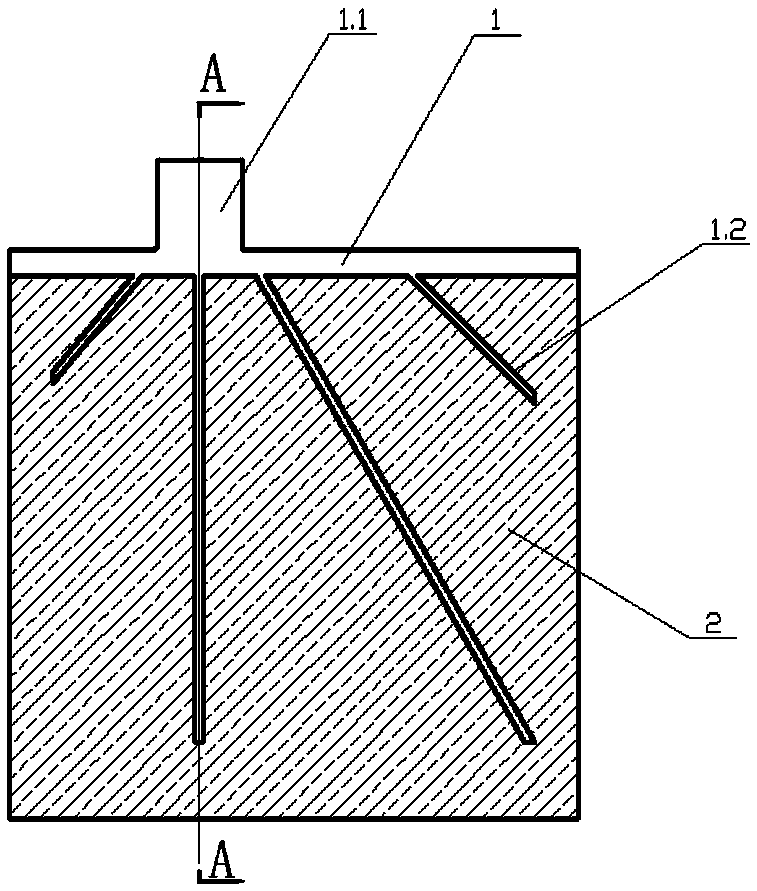

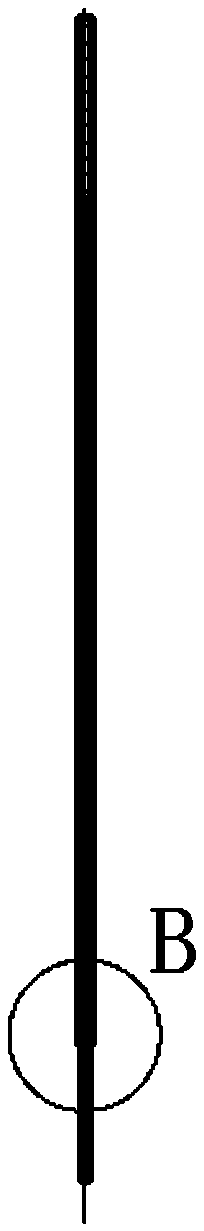

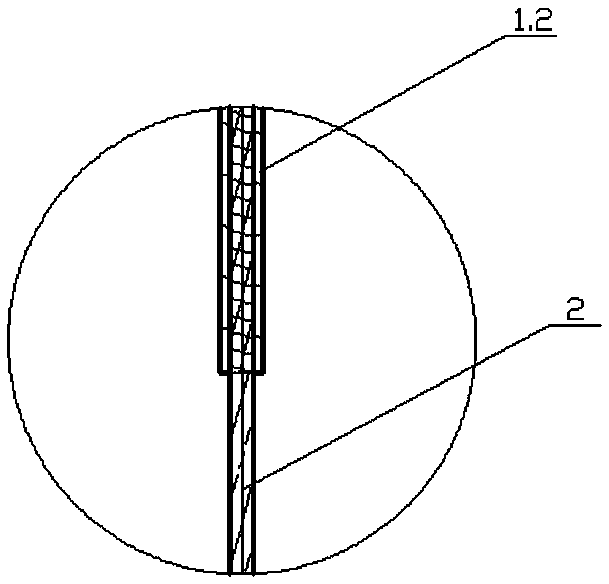

[0016] figure 1 The negative grid of the composite lead-acid battery shown is composed of a skeleton 1 and a plate surface 2 . The skeleton 1 is a comb-shaped lead alloy product, the cross-section of the transverse skeleton at the upper end is rectangular, and the left end of the transverse skeleton is provided with a rectangular tab 1.1 protruding upwards, and the bottom of the transverse skeleton is A plurality of radially arranged ribs 1.2 are also connected downwards, and the cross section of the ribs 1.2 is rectangular. The specification of the lead-acid battery supporting the negative grid in this embodiment is 12V60Ah. Because the specifications are not large, four ribs 1.2 are configured. Among them, the ribs 1.2 located directly below the tabs 1.1 are perpendicular to the transverse frame, and the ribs 1.2 at other positions a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com