Ocean engineering ship type

A marine engineering and ship type technology, which is applied in the direction of hull, hull parts, ship construction, etc., can solve the problems of short rolling period, high initial stability height, large displacement, etc., to improve operating efficiency, seakeeping performance and fast performance , to avoid the effect of violent swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An implementation example of the present invention will be explained in detail below in conjunction with the accompanying drawings.

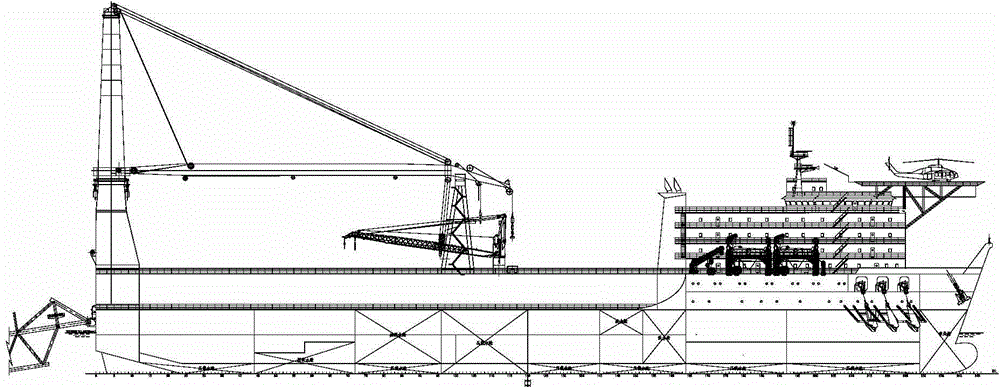

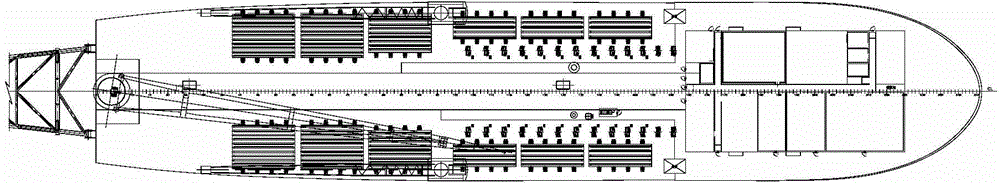

[0017] The invention is applicable to marine engineering ships such as lifting pipe-laying ships, drilling ships, workover ships, platform maintenance ships and the like. Such as figure 2 and image 3 A lifting pipe-laying vessel according to the embodiment of the present invention shown in , has a total length of 172.5 meters and a width of 35 meters.

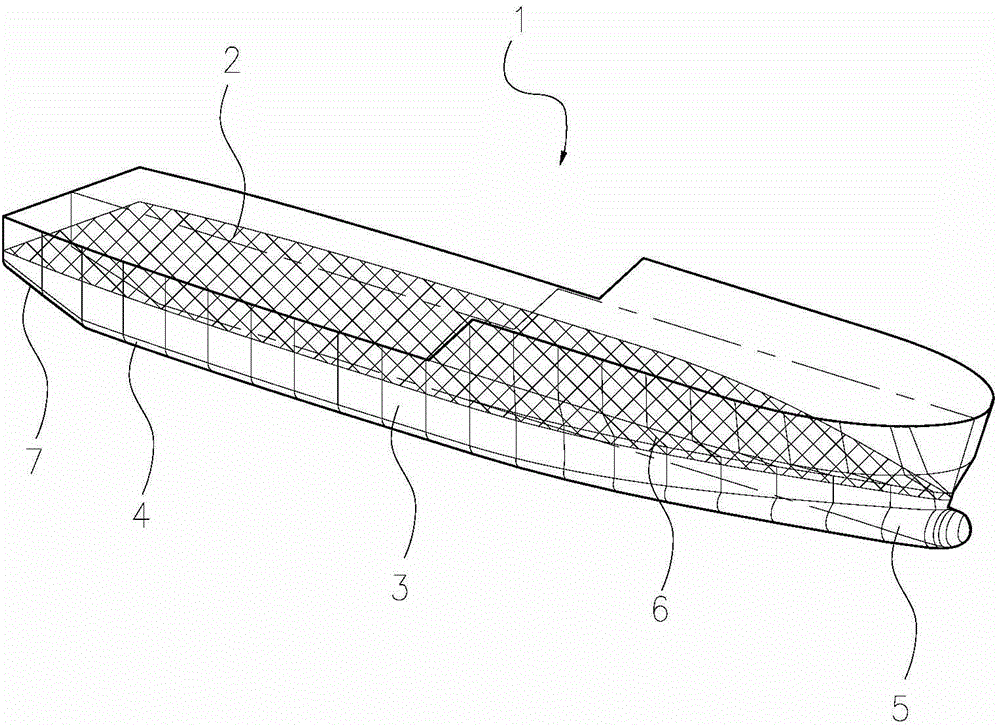

[0018] figure 1 It is the hull form diagram of the present invention, and the ship form 1 has a thin water plane surface 2 . A vertical cylinder 3 is formed along the entire length of the ship by the waterline surface 2, which is the ship's side profile. The side profile of the ship is connected to the bottom of the ship through an arc-shaped bilge 4, preferably a circular arc-shaped bilge. The bottom of the ship includes a raised bottom 7 at the stern to improve the flow field in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com