How to make a storage box

A production method and storage box technology, applied in rigid containers, containers, packaging and other directions, can solve the problems of low production efficiency of storage boxes, inability to achieve mass production, affecting the appearance of storage boxes, etc., and achieve compact structure, not easy to break, not easy to deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

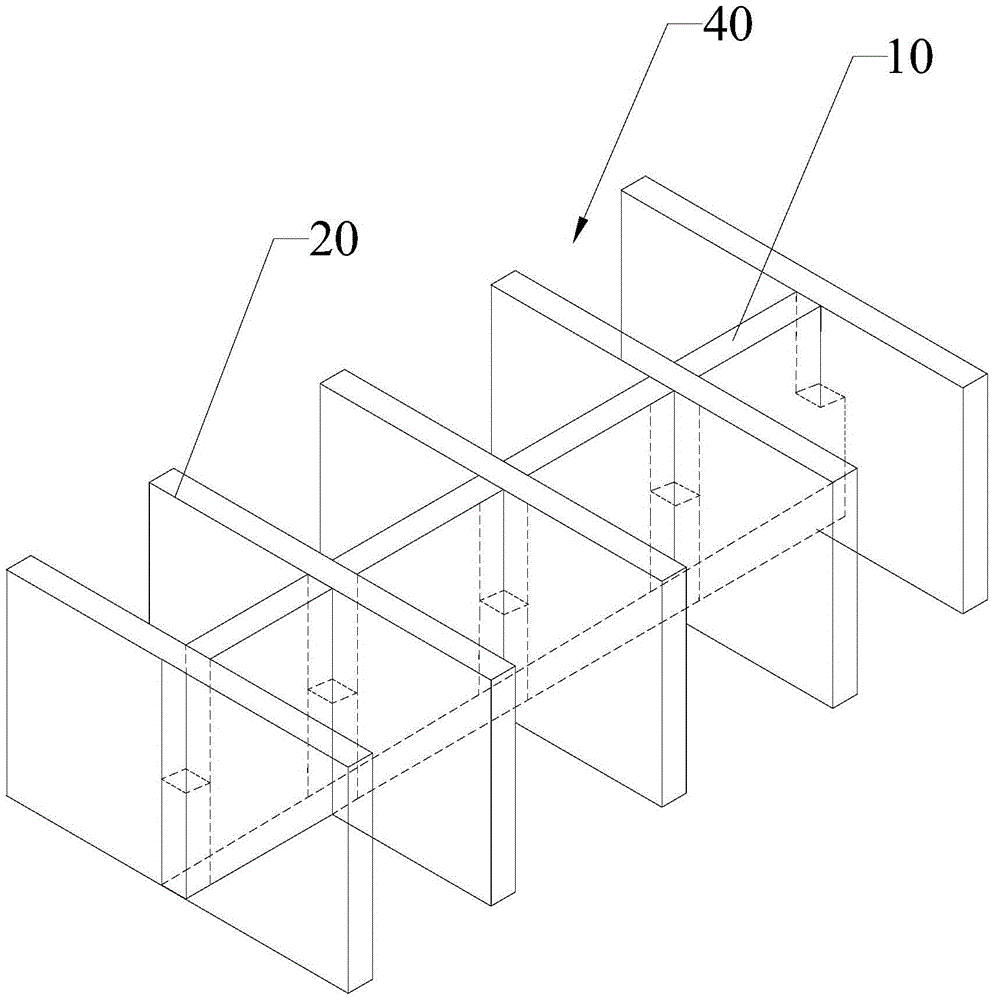

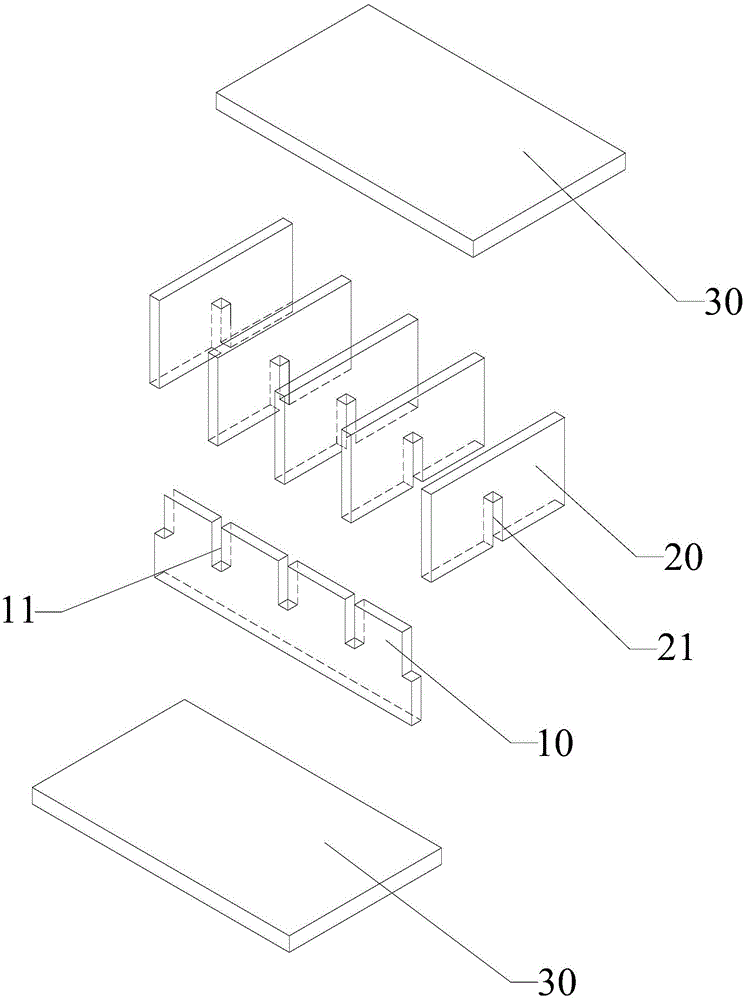

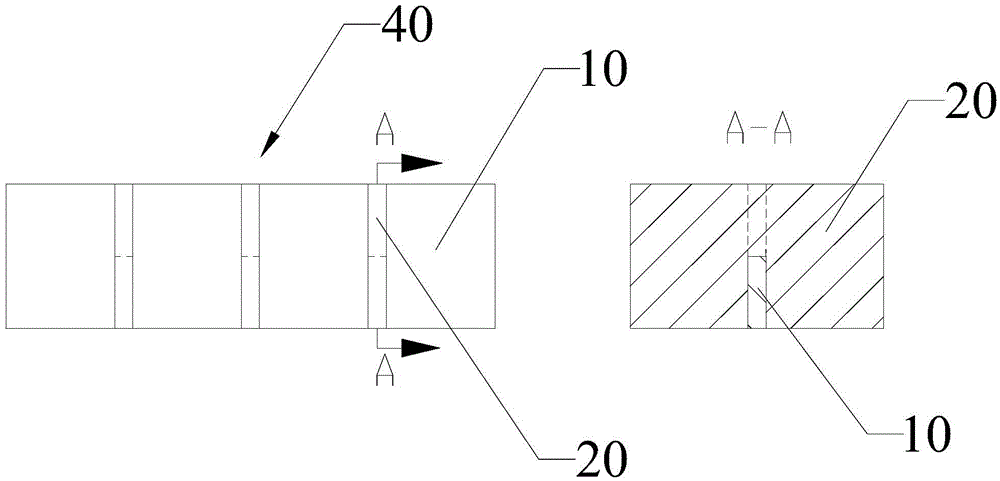

Embodiment 1

[0046] Starting from the end of a long side of a first rectangular plate 10 with a certain length, first U-shaped grooves 11 are provided at equal intervals, and the depth of the first groove corresponding to the first U-shaped groove 11 is the first rectangular Half of the height of the plate 10; get the second plate 20 whose short side height is identical with the height of the first rectangular plate 10, and set up the second U-shaped groove 21 in the center of the long side of the second plate 20, and the second U-shaped groove 21 corresponds to the second plate 20 The depth of the second groove is half of the height of the second plate 20; the first U-shaped groove 11 is compatible with the second U-shaped groove 21; after the first U-shaped groove 11 of the first rectangular plate 10 is inserted into the second plate 20, A grid body 40 is formed; two third plates 30 matching the length and width of the upper and lower end surfaces of the grid body 40 are taken, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com