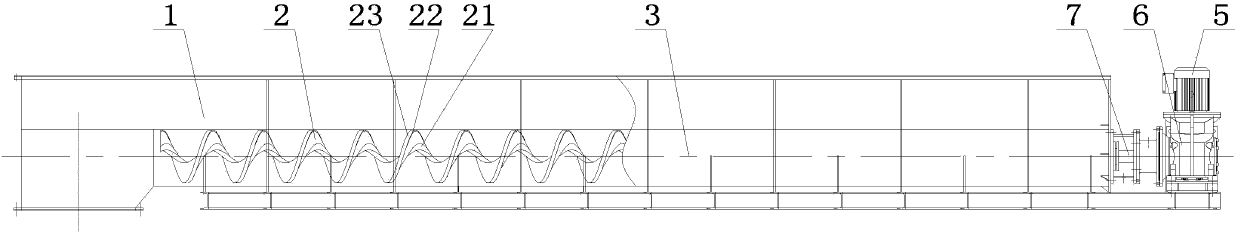

Tri-pipe shaftless spiral garbage feeder

A shaftless screw and feeder technology, applied in the direction of packaging, etc., can solve the problems of insufficient uniformity of feeding in the outlet sealing performance, easy deformation of the screw, and small processing capacity, etc., to achieve good air locking effect, not easy to block, even feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

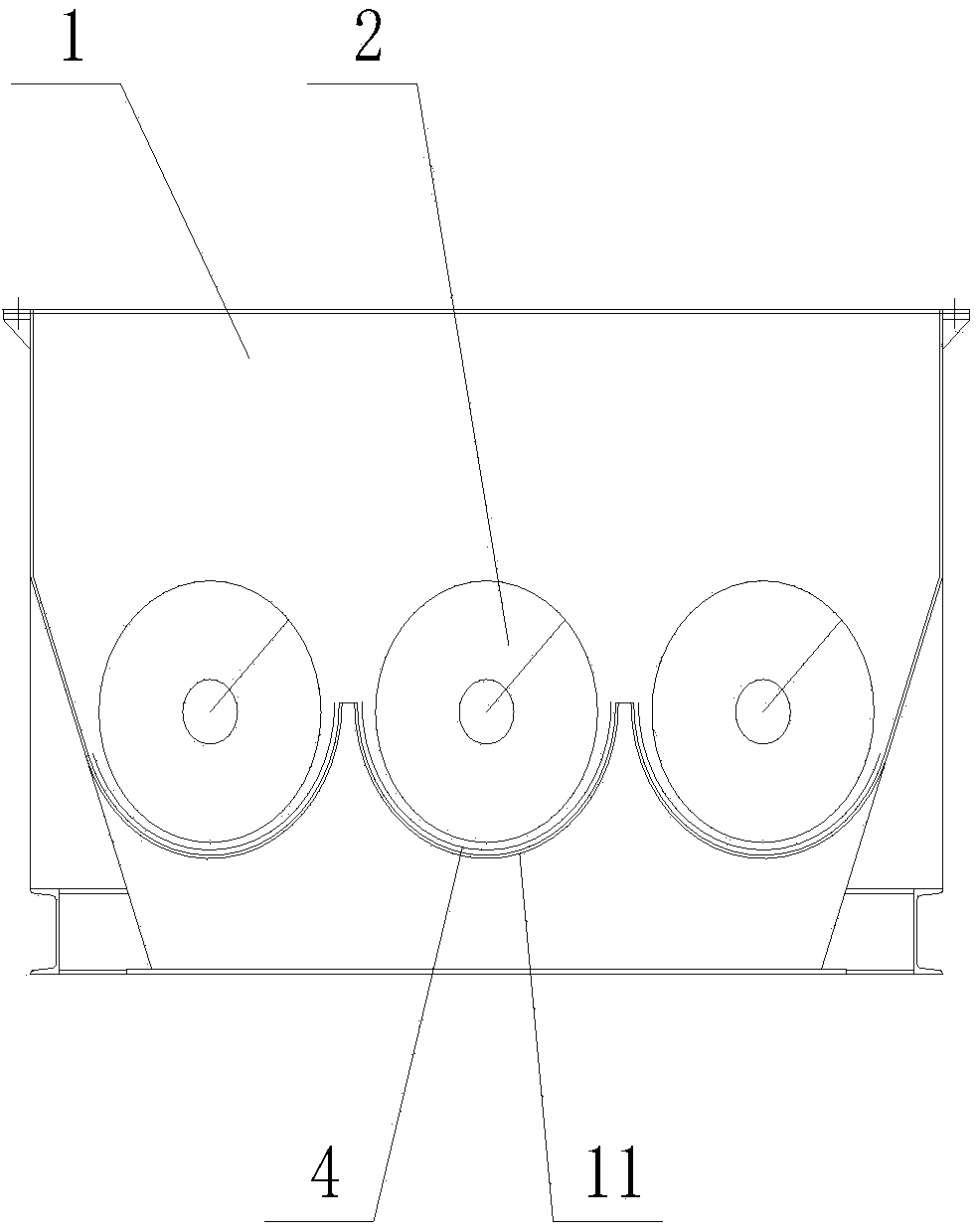

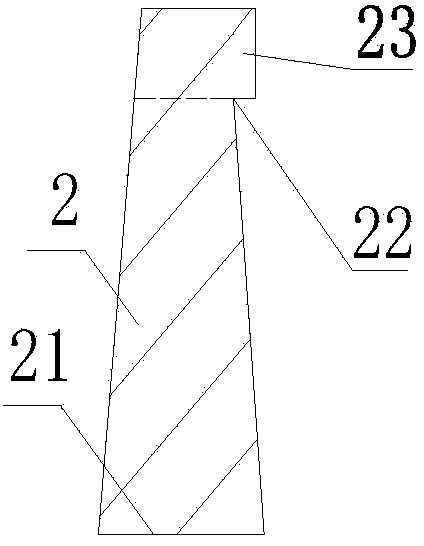

[0021] like Figures 1 to 3 As shown, the three-pipe shaftless spiral garbage feeder includes a body 1. Three spiral bodies arranged side by side are arranged in the body 1. A driving mechanism connected with the spiral body transmission to drive the spiral body to rotate axially is installed on the body 1. The mechanism is electrically connected to the control system and controlled by the control system, wherein the spiral body is a piece of body 2 around an axis 3 ( figure 1 Indicated by the center line) spirally, the spiral extends along the axis 3, the side of the sheet 2 close to the axis 3 is the root 21 of the sheet 2, and the side of the sheet 2 away from the axis 3 is the top 22 of the sheet 2, The root 21 of the sheet body 2 is thicker than other parts of the sheet body 2, and the end surface of the top 22 of the sheet body 2 is provided with a wear-resistant reinforcing rib 23, and the sheet body 2 and the wear-resistant reinforcing rib 23 adopt an integrated struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com