Combined type thread self-locking hydraulic oil cylinder

A hydraulic cylinder and composite technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of poor locking reliability, low output force of hydraulic cylinder, high precision requirements of hydraulic valve, etc., and achieve high output force, output force improvement, locking The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

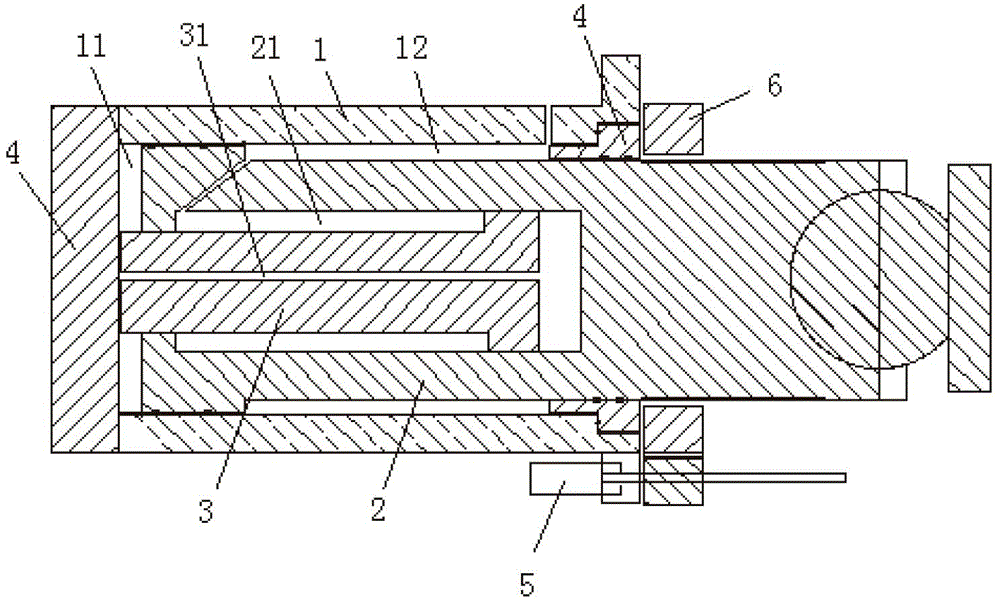

[0015] Such as figure 1 As shown, a compound threaded self-locking hydraulic cylinder provided by the embodiment of the present invention includes a cylinder 1 and a piston, and the left and right ends of the cylinder 1 are respectively closed by a cylinder head 4, which is characterized in that: There are two pistons, one of which is the main piston 2, and the other piston is the auxiliary piston 3;

[0016] The main piston 2 is installed in the inner cavity of the cylinder 1 in a sliding fit manner, and divides the inner cavity of the cylinder 1 into two independent sub-cavities on the left and right sides, wherein the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com