Processing method and equipment of dried jasmine slices

A processing method, jasmine flower technology, applied in botany equipment and methods, plant preservation, decorative art, etc., can solve the problems of low production efficiency, few types of products, low quality, etc., to improve work efficiency, reduce production costs, The effect of a broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The processing method of jasmine dried sheet, its concrete processing steps are:

[0022] The first step is jasmine flower picking: the picking time is from 10:00 to 17:00 every day during the jasmine blooming season. During the picking process, the flowers are packed in mesh bags. The mesh bags have good air permeability to prevent the jasmine from being stuffy. Place it indoors below 30°C until the flower stalks are cut off.

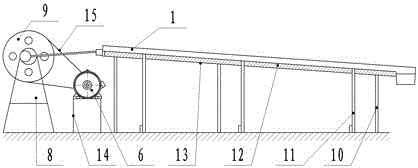

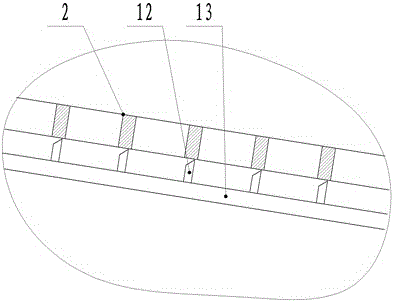

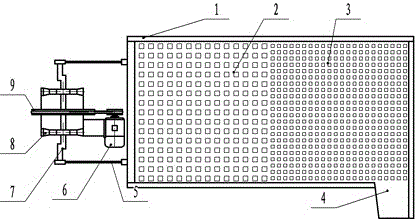

[0023] The second step is to cut the flower stalks: put the picked flowers on the jasmine vibrating handle cutter, turn on the power, and the jasmine flower stalks will be cut off automatically.

[0024] The third step is to grow flowers: place the jasmine flowers with cut off flower stalks in a room at 25-38°C for 1-2 hours to make them open and emit fragrance, but the time for flower cultivation and fragrance cannot be prolonged, otherwise the fragrance will be released Exhausted.

[0025] The fourth step is drying: put the jasmine flowers w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com