Purline clamp integrated structure connecting metal roof and photovoltaic support

A metal roof and photovoltaic bracket technology, applied in the field of solar photovoltaic, can solve the problems of difficult installation of photovoltaic brackets, difficult installation, waste of materials, etc., and achieve the effects of good corrosion resistance, reduced installation difficulty, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

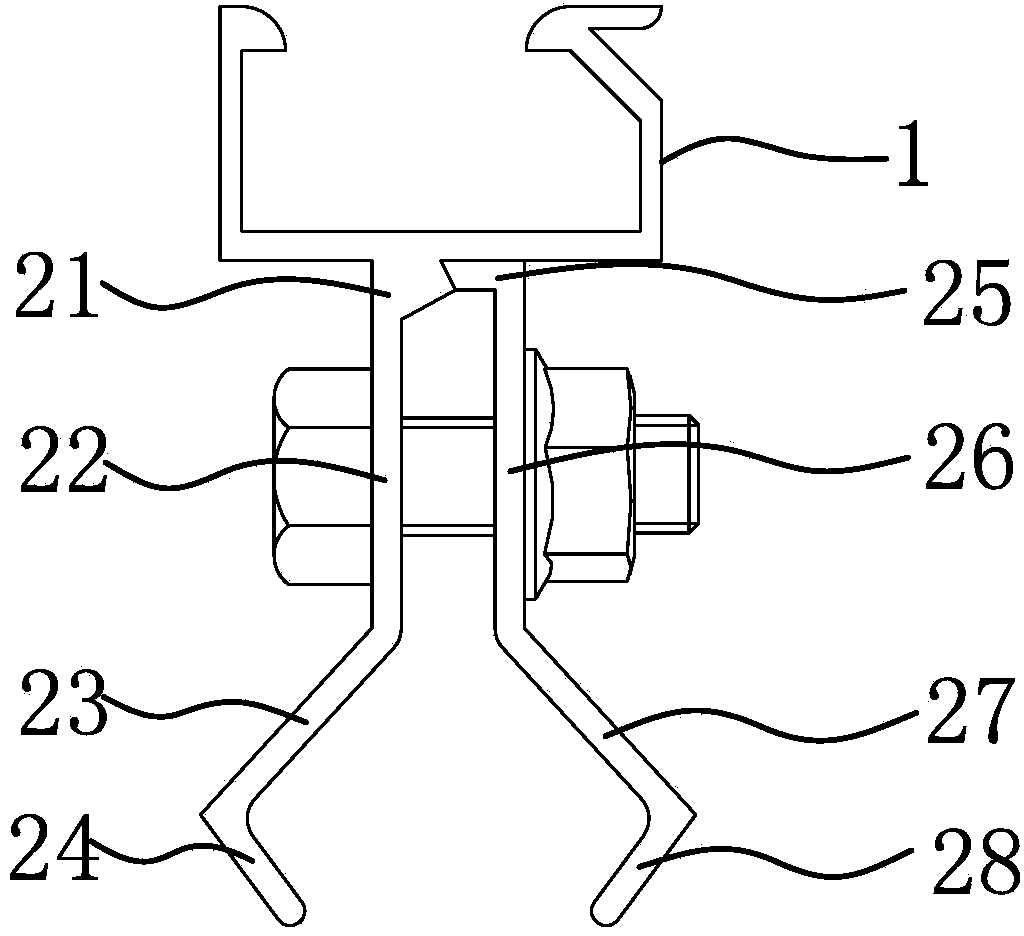

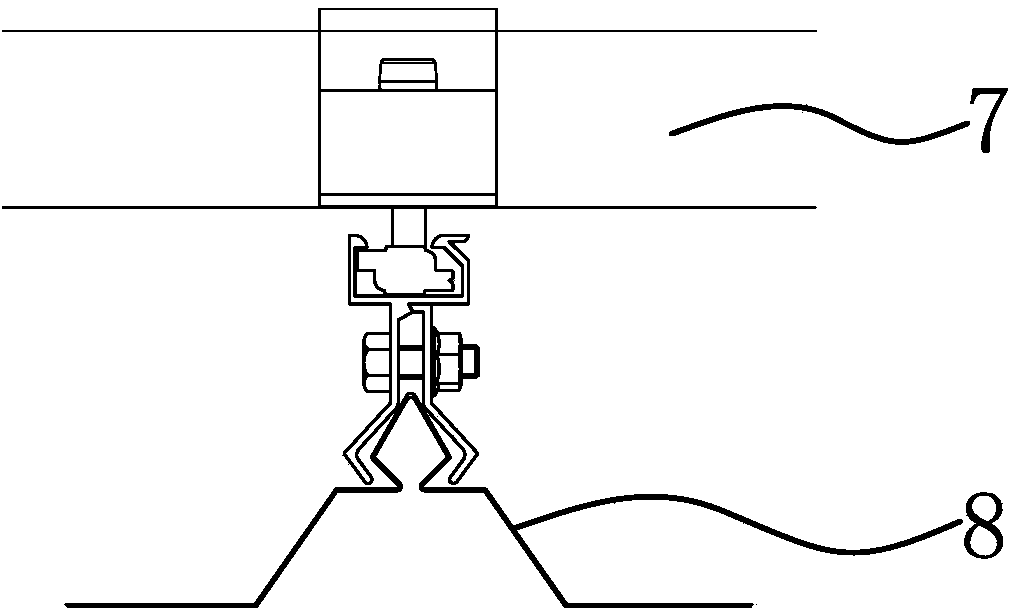

[0037] Such as figure 1 As shown, the integrated structure of the purlin 1 fixture connecting the metal roof 8 and the photovoltaic support 7 includes the purlin 1, and the purlin 1 extends downward along the cross-sectional direction to form a first splint, and the first splint is detachably connected by bolts There is a second clamping plate, and the first clamping plate cooperates with the second clamping plate to form a clamping part for clamping the 8 ribs of the metal roof.

[0038] The first splint has a first left base body 21, the first left base body 21 is connected to the purlin 1, a concave portion is set on the top of the right side of the first left base body 21, and a second bottom of the first left base body 21 is arranged in turn. A left vertical plate 22, a first left outwardly inclined plate 23 and a first left inwardly inclined plate 24; the second clamping plate has a first right base body 25, and the top of the first right base body 25 has a second groove...

Embodiment 2

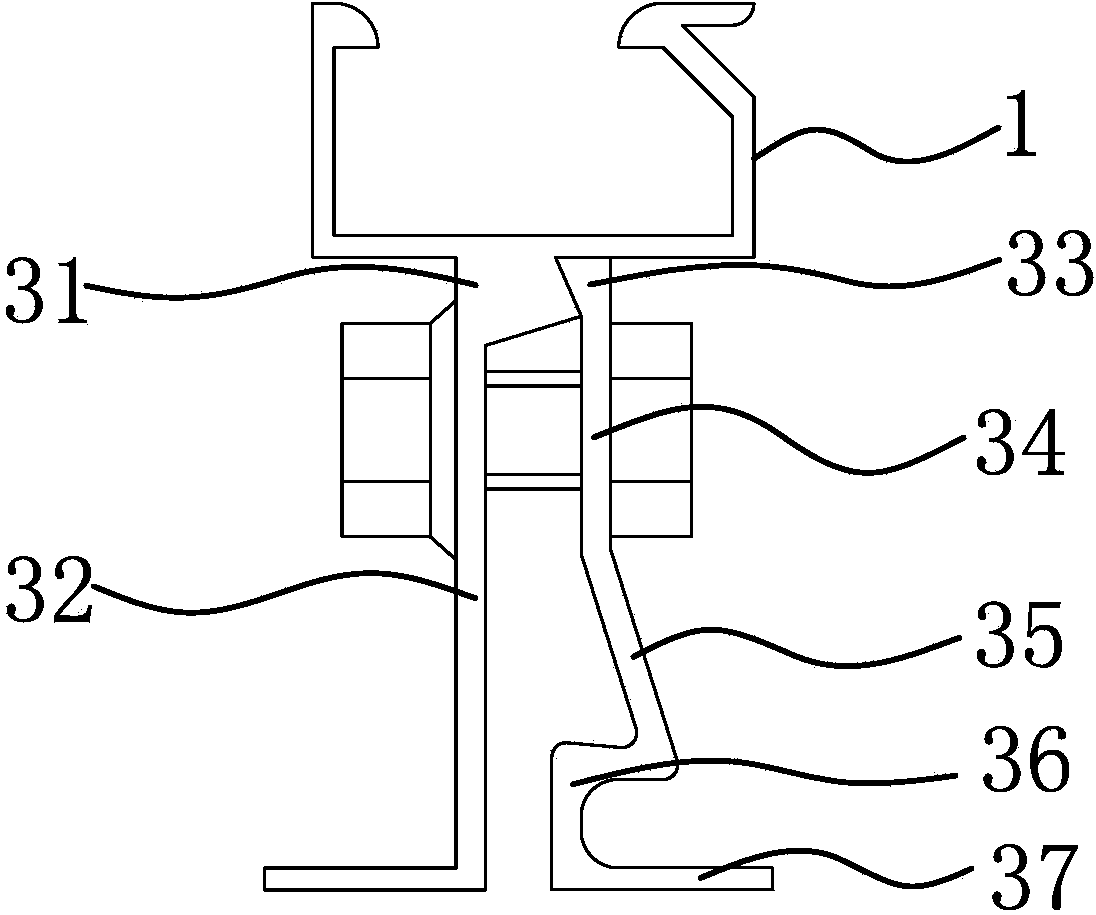

[0044] Such as Figure 3-4 As shown, the part of the purlin 1 is the same as the first embodiment, the difference lies in the splint, the first splint has a second left base 31, the top of the second left base 31 is connected with the purlin 1, and the second The top of the right side of the left base body 31 is provided with a recess, and the second left base body 31 bottom is provided with a second left L-shaped plate 32; the second splint has a second right base body 33, and the top of the second right base body 33 has a The second connecting portion with matching concave shape, the second right base 33 is provided with a second right vertical plate 34 , a second right camber plate 35 , a second right horizontal plate 36 and a second right L-shaped plate 37 in sequence.

[0045] Other structures and usage methods are the same as those in Embodiment 1, and will not be described in detail.

Embodiment 3

[0047] Such as Figure 5-6 As shown, the part of the purlin 1 is the same as the first embodiment, the difference lies in the plywood, the first plywood has a third left base 41, and the top of the third left base 41 is connected to the purlin 1, so The top of the right side of the third left base 41 is provided with a recess, and the third left L-shaped plate 42 is provided at the bottom of the third left base 41; the second splint has a third right base 43, and the top of the third right base 43 has The third connecting portion matching the shape of the recess, the third right base 43 is provided with a third right vertical plate 44 , a third right camber plate 45 and a third right L-shaped plate 46 in sequence.

[0048] Other structures and usage methods are the same as those in Embodiment 1, and will not be described in detail.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap