processing module

A technology for processing modules, processing chambers, used in transport and packaging, coating, conveyor items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

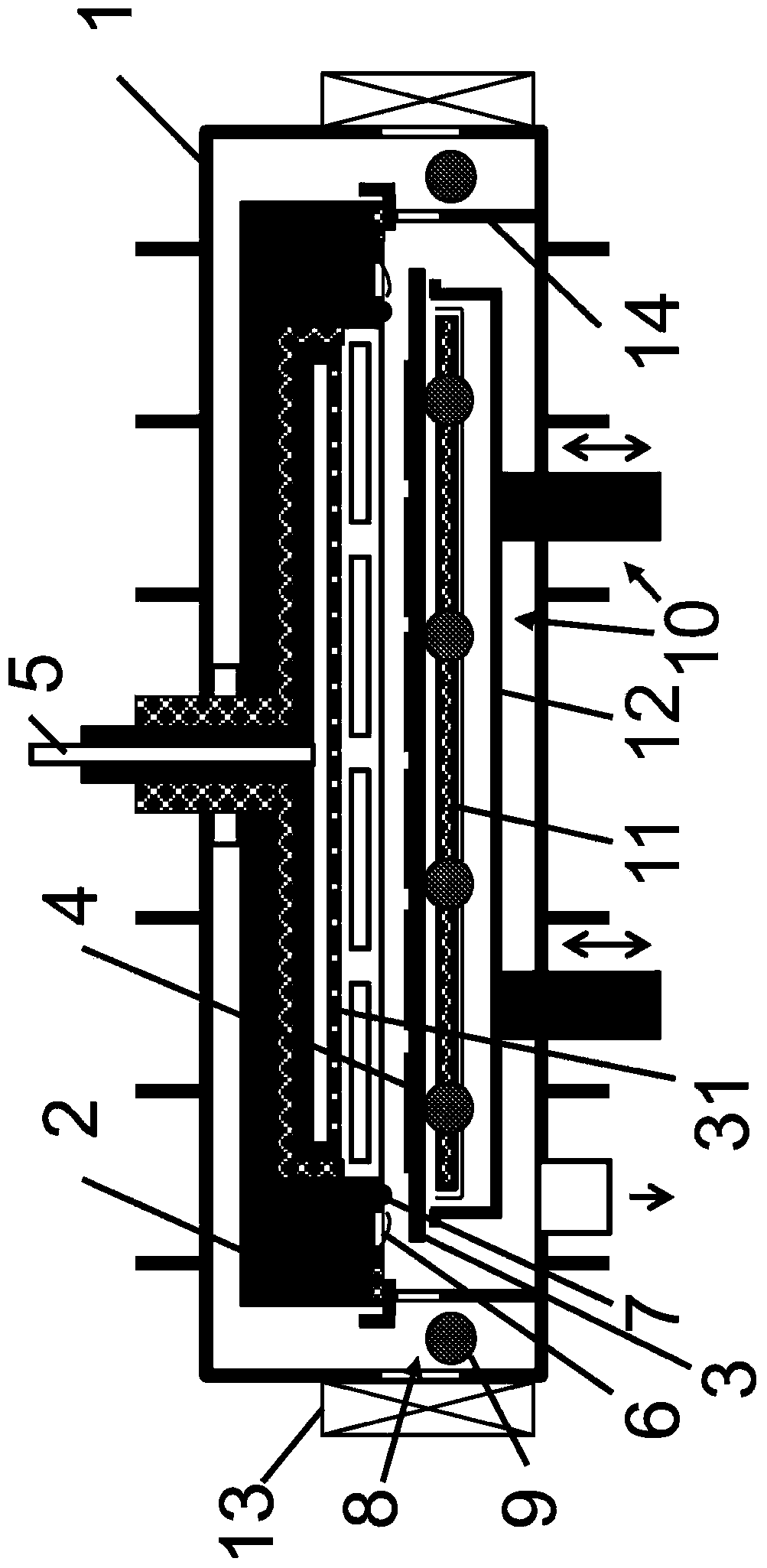

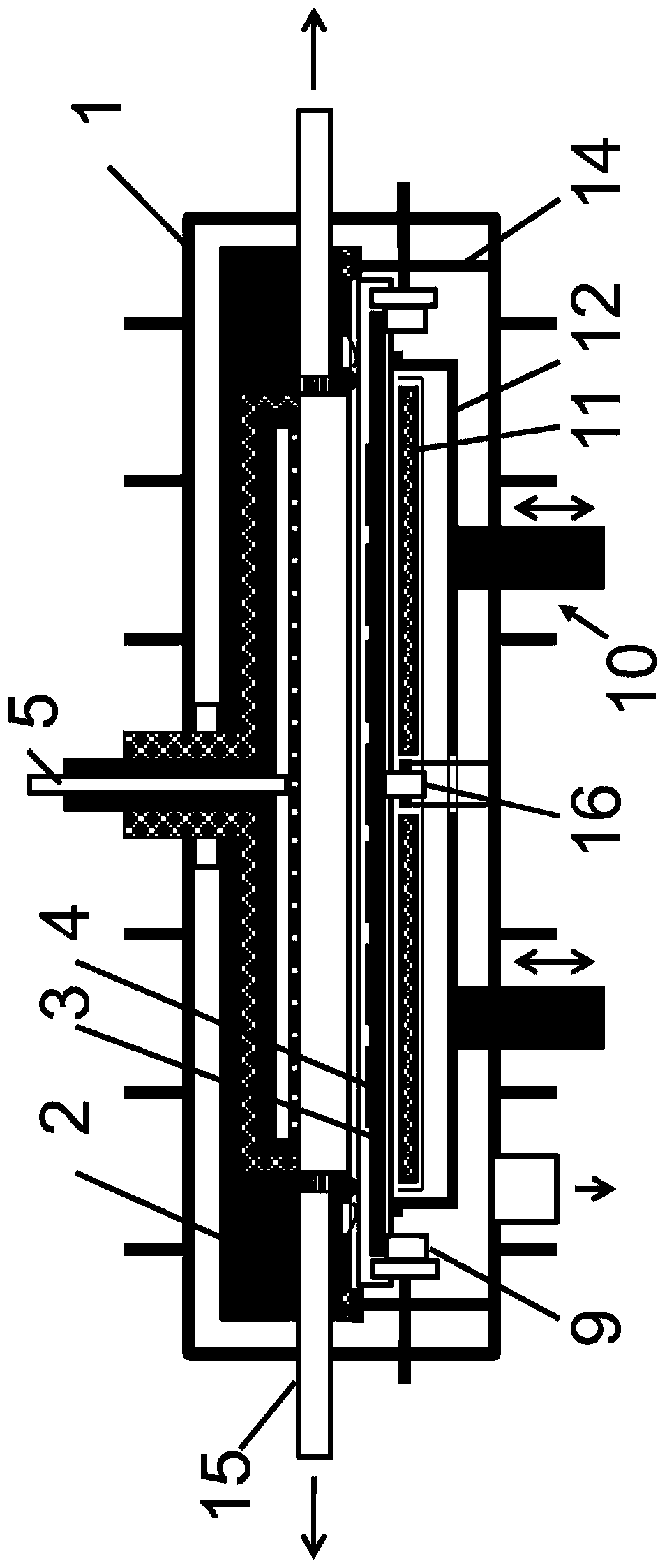

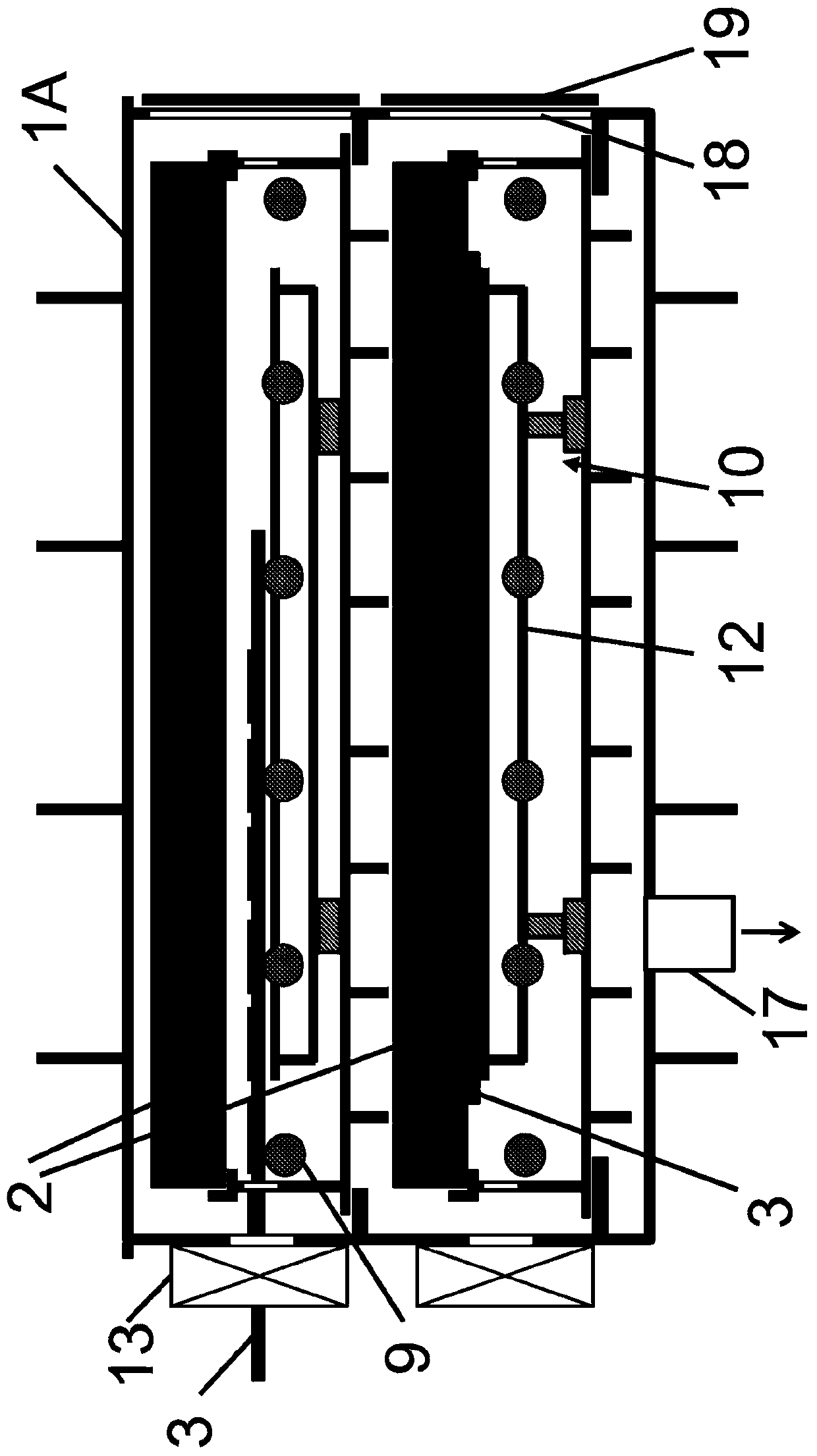

[0051] figure 1 An embodiment of a processing module according to the invention is schematically shown in a vertical section in the direction of substrate transport. A processing chamber 2 is located in the processing module 1 . The carrier device 3 is used as the bottom of the processing chamber 2 , and the substrate 4 is placed flat on the carrier device 3 . exist figure 1 The processing chamber 2 exemplarily shown in is a parallel plate reactor for coating a substrate 4 with a plasma-assisted deposition layer.

[0052] The gaseous starting material for the layer deposition is guided in the process chamber 2 via the gas connection assembly 5 into the gas shower 31 . The gas sparger 31 serves as the first HF electrode in the parallel plate reactor. The carrier 3 with the substrate 4 is the second electrode of the parallel-plate reactor, which is aligned parallel to the gas shower 31 .

[0053] In order for HF electrical power to flow from the gas shower 31 via the carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com