Automatic direction-changing lifting device for vehicle

A lifting device and vehicle technology, applied in the direction of buildings, building types, buildings, etc. where cars are parked, can solve problems such as inconvenient operation, unstable operation, complex structure, etc., and achieve convenient operation, convenient access to vehicles, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

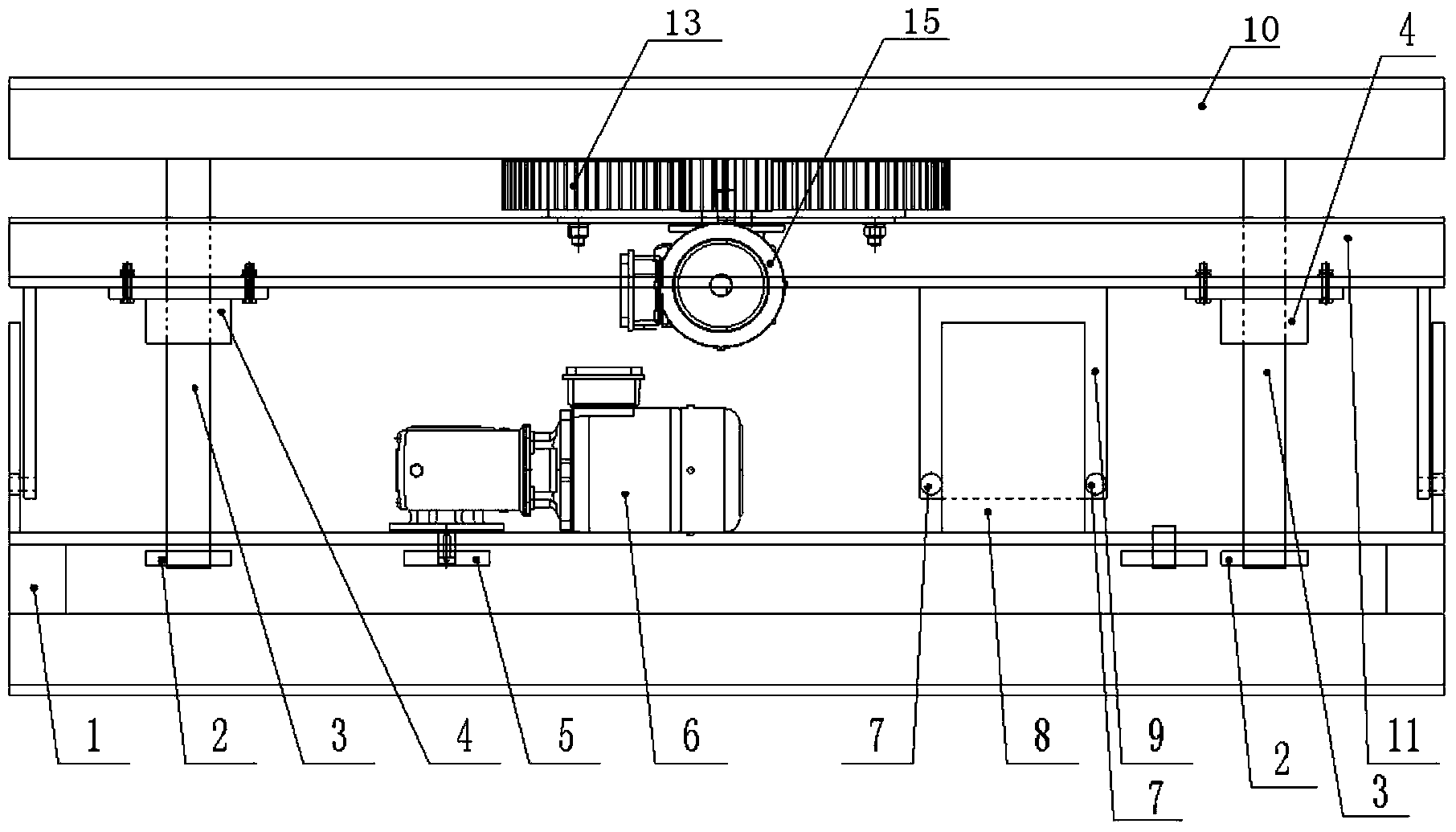

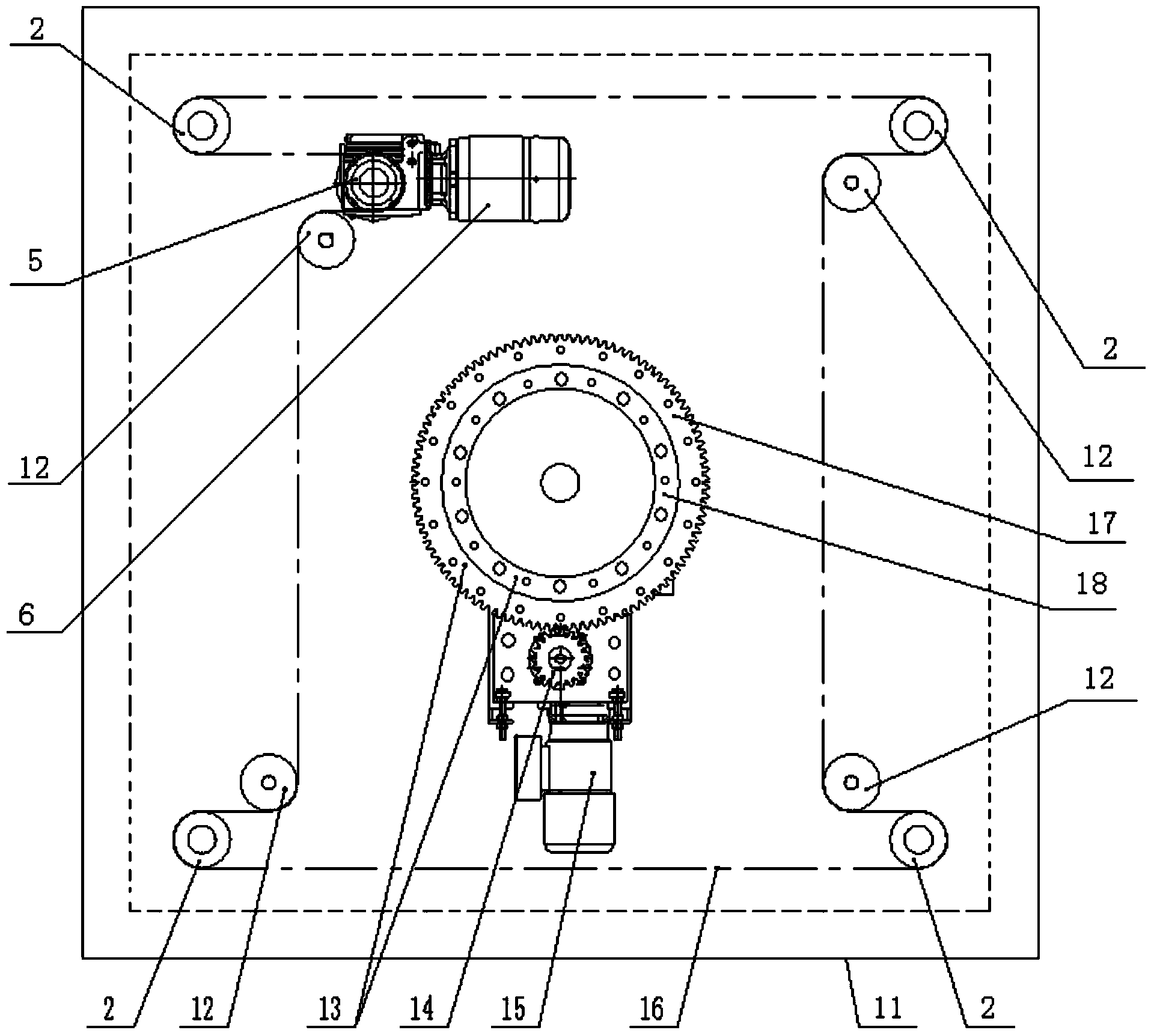

[0028] Such as figure 1 , figure 2 As shown, the present invention comprises base 1, rotating platform 10, lifting platform 11, leading screw 3, lifting driving motor 6, rotating driving motor 15, slewing support 13, leading screw nut 4, drive chain 16, rotating platform 10, lifting platform 11. The bases 1 are arranged parallel to each other with gaps between them. The rotating platform 10, lifting platform 11, and base 1 are arranged horizontally from top to bottom with gaps between them. Other working devices are installed between the gaps. part. The rotating platform 10 is located at the top of the whole device, the base 1 is located at the bottom of the whole device, the lifting platform 11 is located betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com