Sealing member, manufacturing method for sealing member and container for electric storage device

A technology for sealing parts and manufacturing methods, applied in the direction of sealing/supporting devices, electrochemical generators, battery pack components, etc., capable of solving problems such as unfavorable economy, gas intrusion, and small volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0134] Below, refer to Figure 1~3 The present invention will be described in detail based on examples, but the present invention is not limited thereto.

[0135]

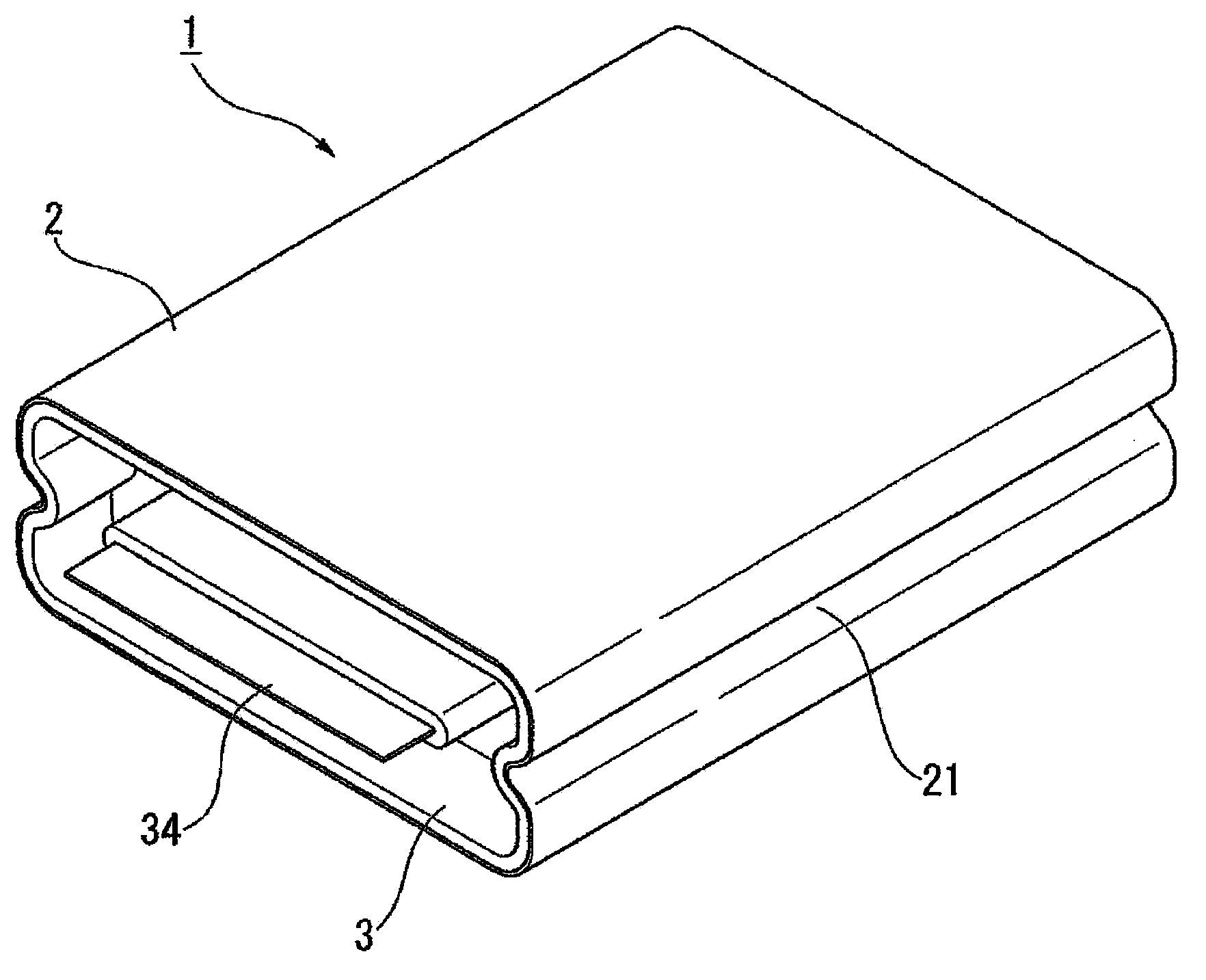

[0136] Metal foil made of 12 μm aluminum foil and a sealant layer made of 60 μm non-stretched PP film are dry-laminated on one side of a 15 μm biaxially stretched nylon 6 film using a polyurethane-based adhesive to obtain a metal Laminated film of foil. The laminated film was cut into a rectangle of 60 mm x 130 mm. With the sealant layer of the laminated film cut into a rectangle as the inside, the two ends of the short sides overlap each other by 10 mm and are welded together to form a palm-shaped sealing part (not shown), thereby producing the cylindrical film 2 . The palm-shaped sealing portion is creased so as to overlap the unwelded cylindrical diaphragm 2 .

[0137]

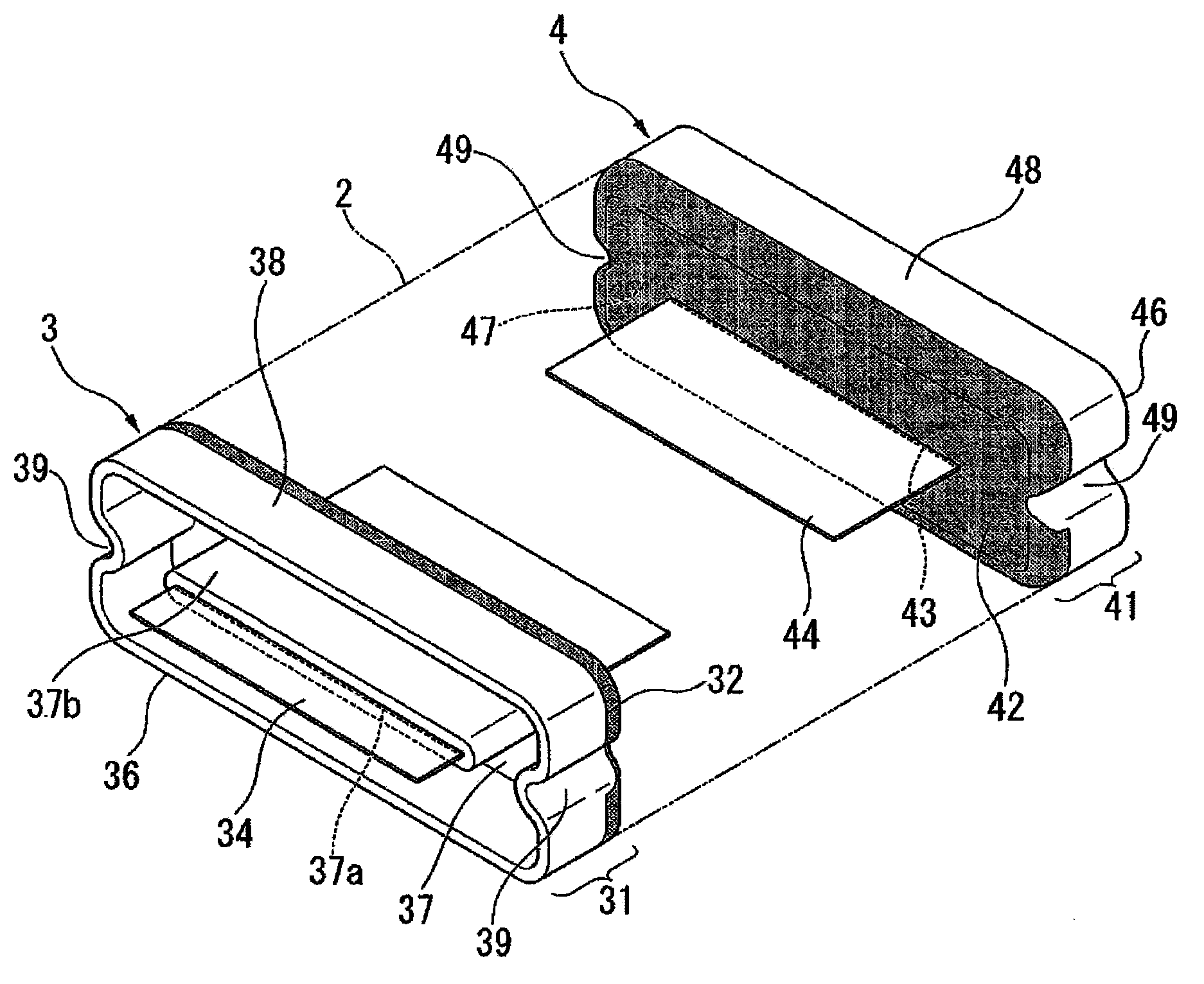

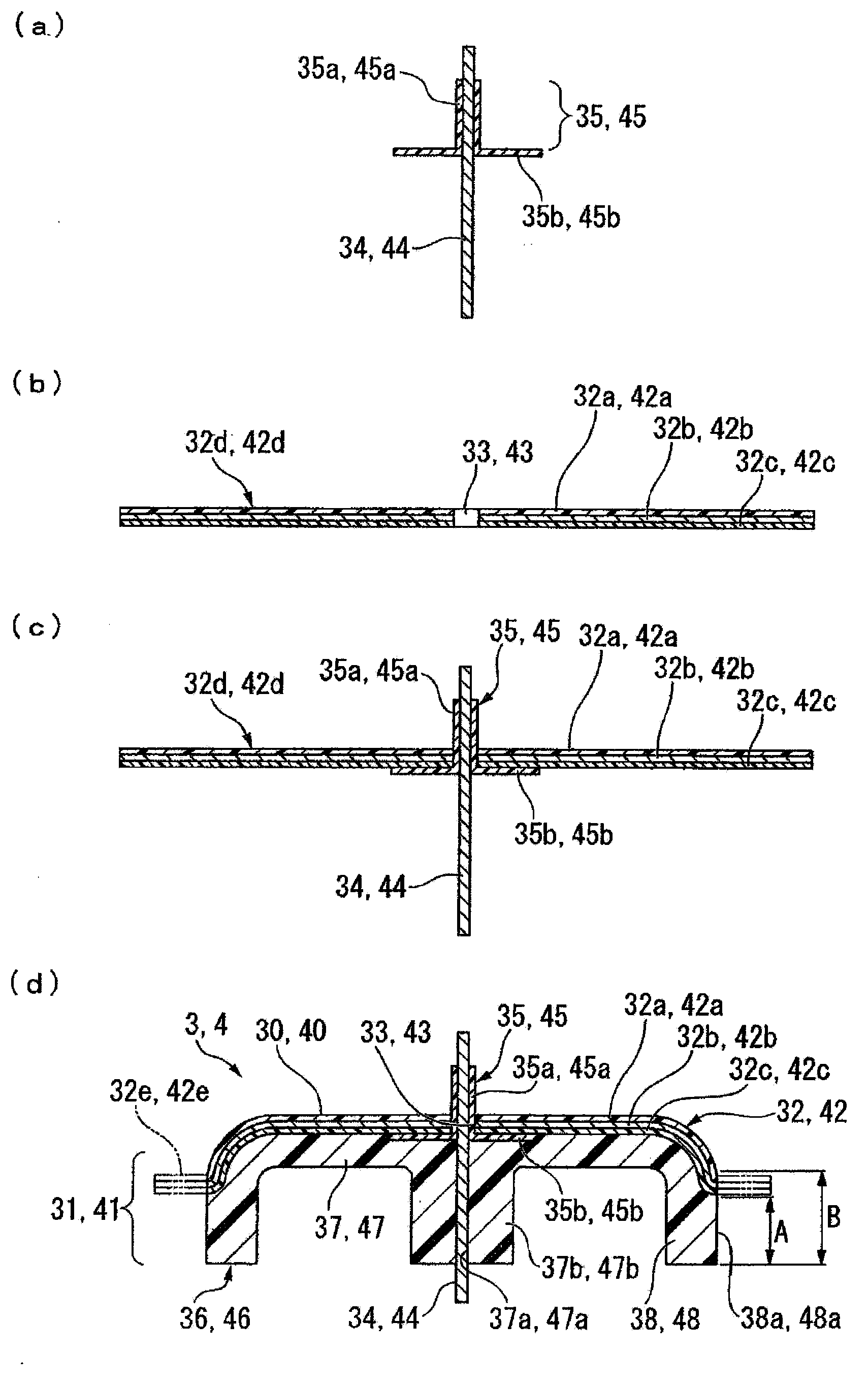

[0138]As electrode members, a positive electrode member 34 made of aluminum foil with a length of 25 mm, a width of 25 mm, and a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap