wiper cover assembly

A cover and wiper technology, which is applied in the field of automobile manufacturing, can solve the problems of large lap gap and surface difference, affecting the natural and beautiful transition of peripheral parts, and inconvenient installation and disassembly of the decorative block of the wiper cover. The effect of lap gap and surface difference, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

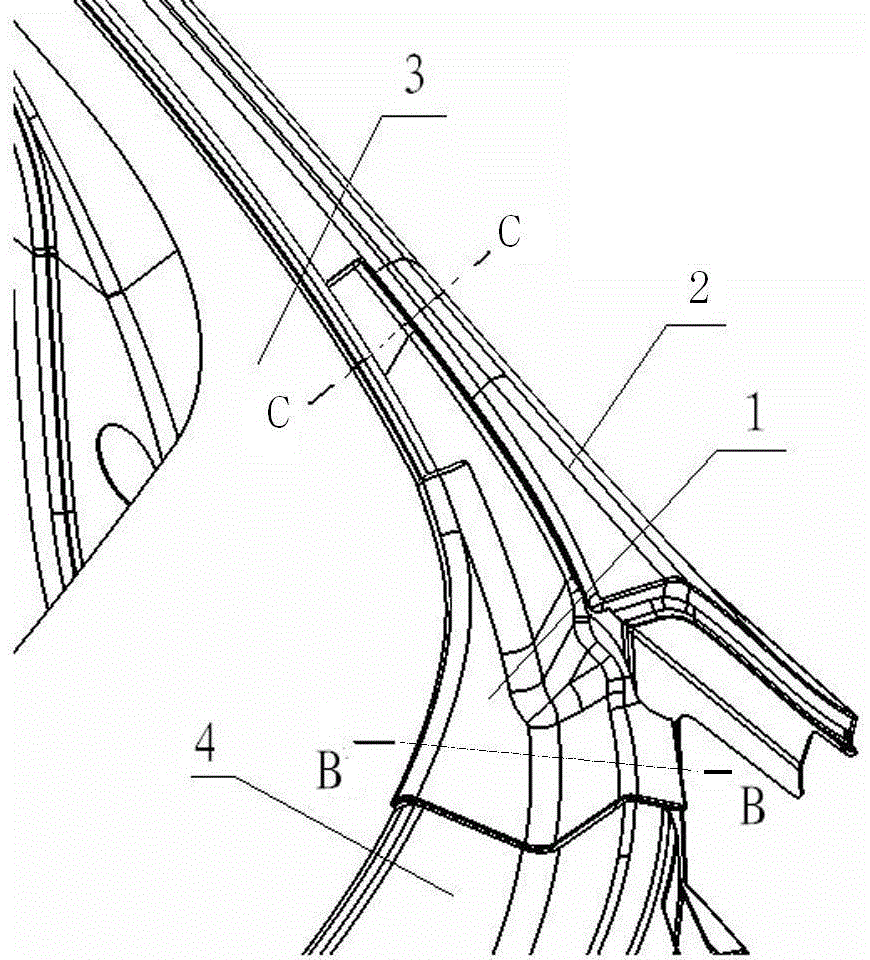

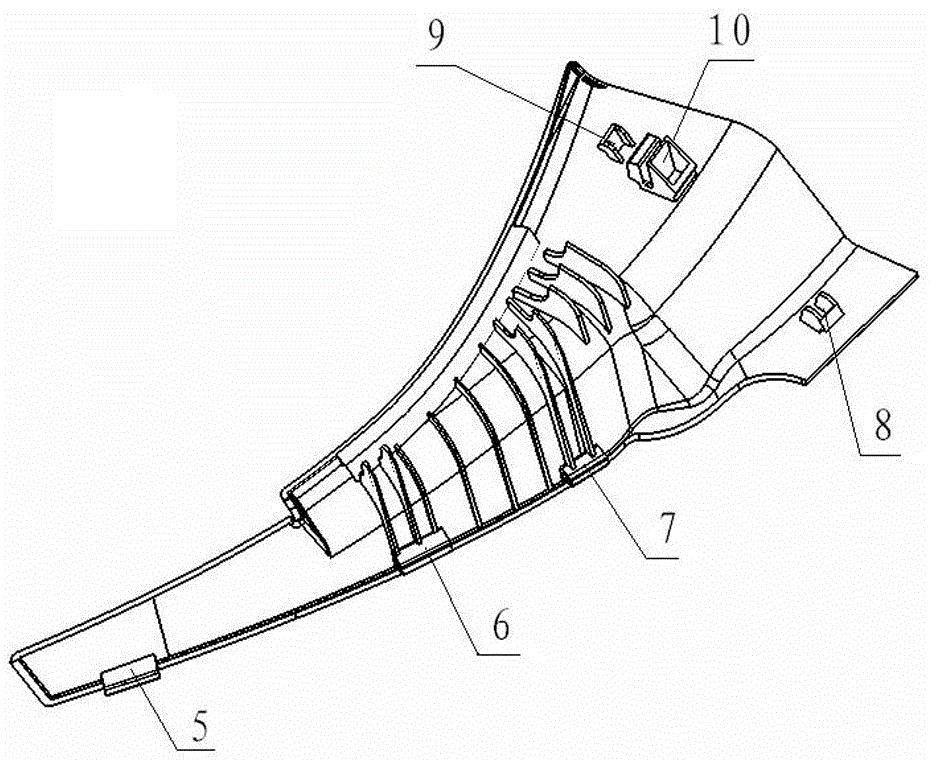

[0015] figure 1 and figure 2 The wiper cover assembly, after the wiper cover decorative block 1 is assembled with the wiper cover body 4 through the fourth hook 8, the fifth hook 9 and the sixth hook 10, it can be The extension direction of the panel body 4 has a certain amount of adjustment, and then the first hook 5 , the second hook 6 and the third hook 7 are engaged with the A-pillar 2 .

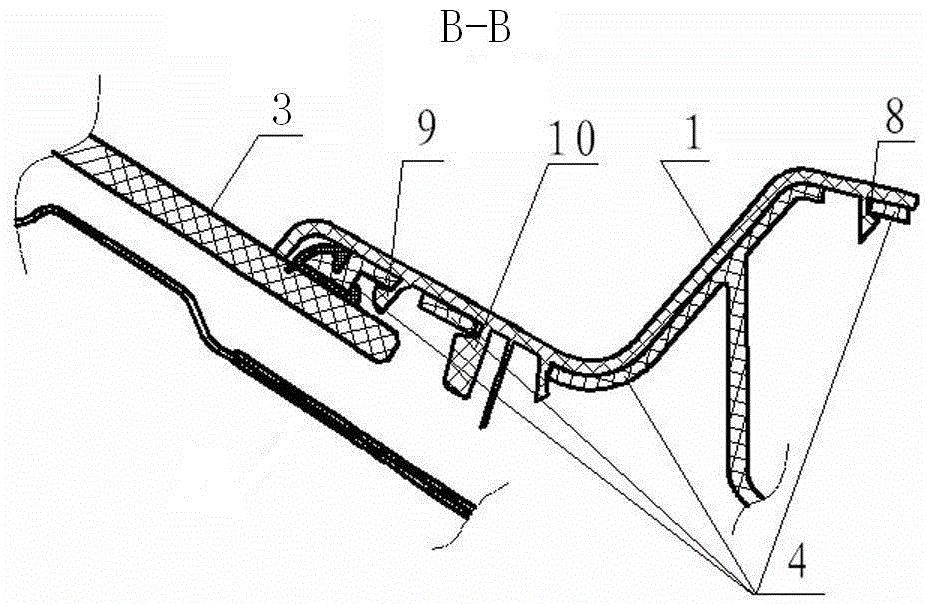

[0016] exist image 3 Among them, the wiper cover decorative block 1 is clamped with the wiper cover body 4 through the fourth hook 8 and the fifth hook 9 on it, which ensures that the wiper cover decorative block 1 and the wiper cover body 4 The function of the fifth hook 9 is to prevent the separation between the wiper cover decorative block 1 and the front windshield 3; through the above hook clamping structure, the wiper cover decorative block 1 can effectively Absorbs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com