A washing machine equipped with an upper cover closing buffer device

A technology of a buffer device and a washing machine, which is applied in the field of washing machines, can solve the problems that the reliability of the buffer device cannot be effectively improved, and achieve the effects of simple structure, avoiding downward force, and preventing collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

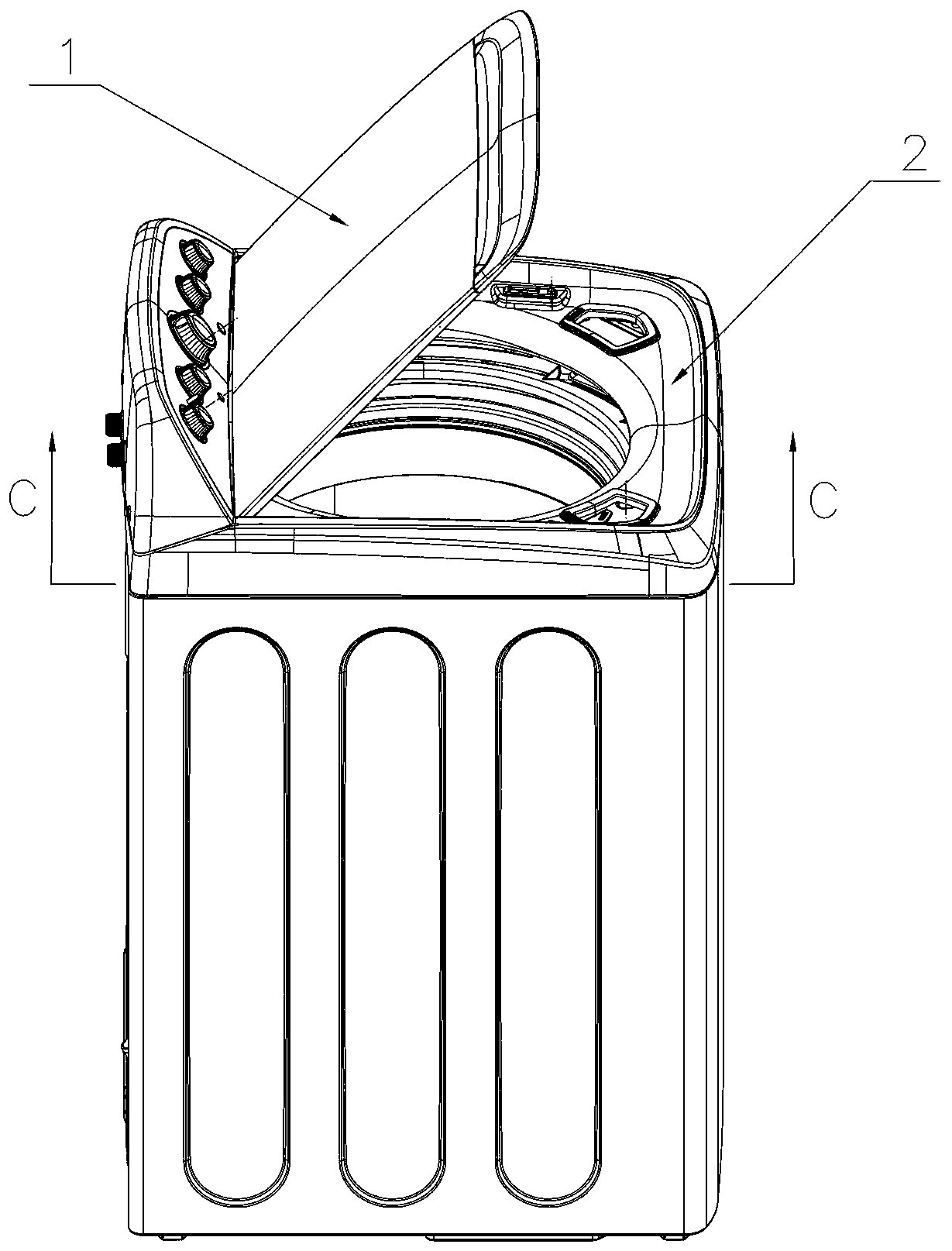

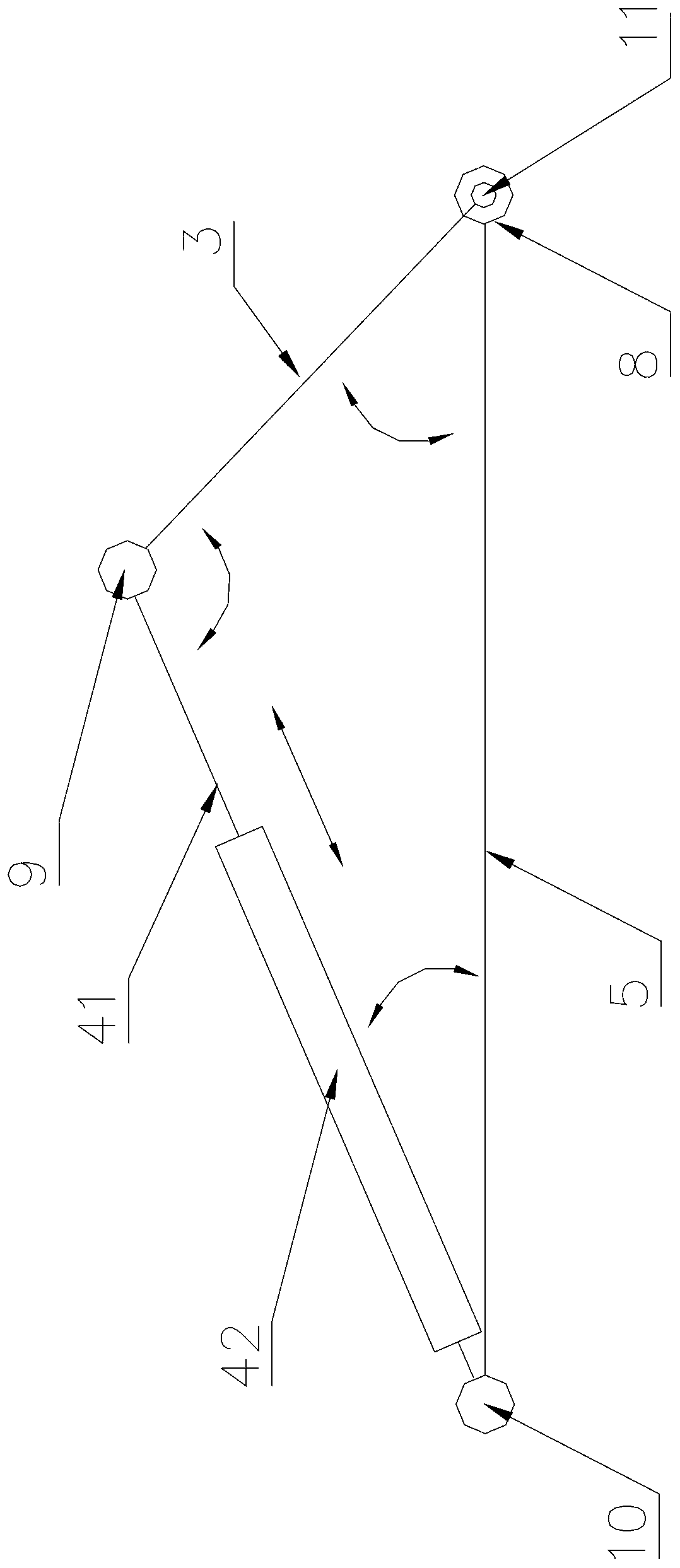

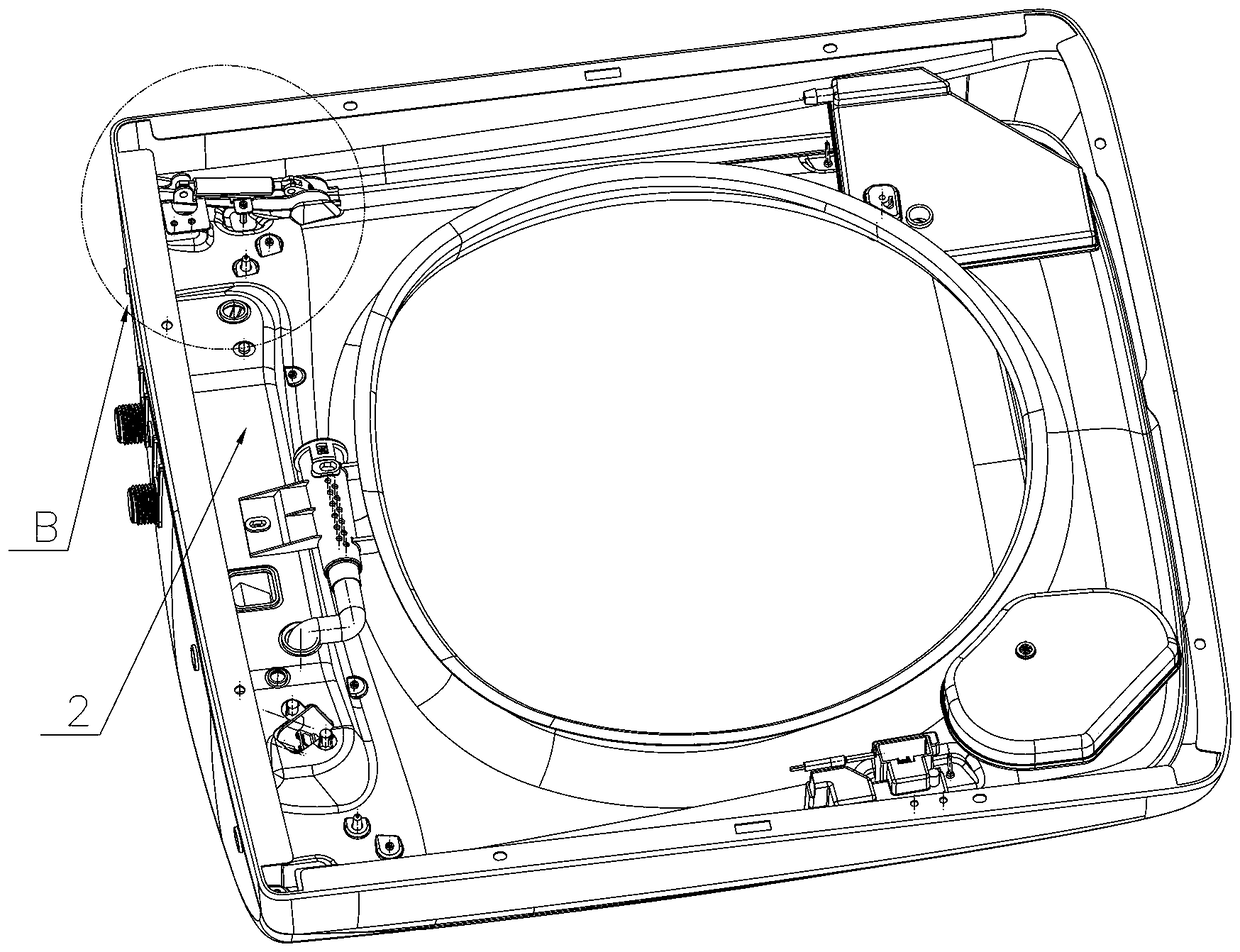

[0033] Such as Figure 1 to Figure 6 As shown, a washing machine equipped with an upper cover closing buffer device includes: a control panel base 2 and an upper cover 1 connected to the control panel base 2 . An upper cover closing buffer device is arranged between the upper cover 1 and the control panel base 2 , and the upper cover closing buffer device is mainly composed of a crank linkage mechanism composed of an air / hydraulic buffer cylinder 4 and a crank 3 . The air / hydraulic buffer cylinder 4 includes a pressure cylinder 42 and a piston rod 41 movably arranged in the pressure cylinder 42. The fixed end 43 of the pressure cylinder 42 is movably connected with the washing machine control panel base 2. The piston The movable end 44 of the rod 41 is rotatably connected with the crank 3 which is fixedly connected with the rotating shaft 11 .

[0034]In this embodiment, the air / hydraulic buffer cylinder 4 can be configured as a buffer cylinder, or as a hydraulic buffer cylin...

Embodiment 2

[0047] Such as Figure 1 to Figure 5 Shown, a kind of washing machine that the loam cake closing buffer device as described in embodiment 1 is housed. One end of the rotating shaft 11 of the upper cover 1 is provided with the above-mentioned upper cover closing buffer device mainly composed of the air / hydraulic buffer cylinder 4 and the crank 3 . The air / hydraulic buffer cylinder 4 and the crank 3 are installed on the control panel base 2 through the fixed frame 5 .

[0048] In this embodiment, the air / hydraulic buffer cylinder 4 can also be arranged at one or more places along the axis of the rotating shaft 11 . Preferably, air / hydraulic buffer cylinders 4 are respectively provided at both ends of the rotating shaft 11 . Therefore, the upper cover can be closed more smoothly, preventing lateral movement and instability.

[0049] In this embodiment, the upper cover 1 can be set to be pivotally connected to the control panel base 2 only through the rotating shaft 11; it can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com