An anti-freezing device using an air-water nozzle

An air-water nozzle and anti-freezing technology, applied in water conservancy projects, water conservancy engineering equipment, buildings, etc., can solve problems such as maintenance difficulties, loosening of protective blocks, and reduction of durability of buildings (structures) to achieve equipment maintenance. Convenience, avoid destructive effect, clear ice-breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

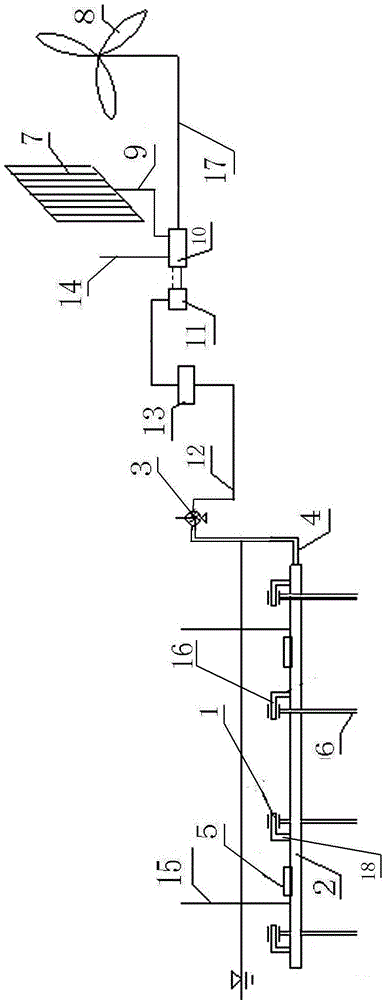

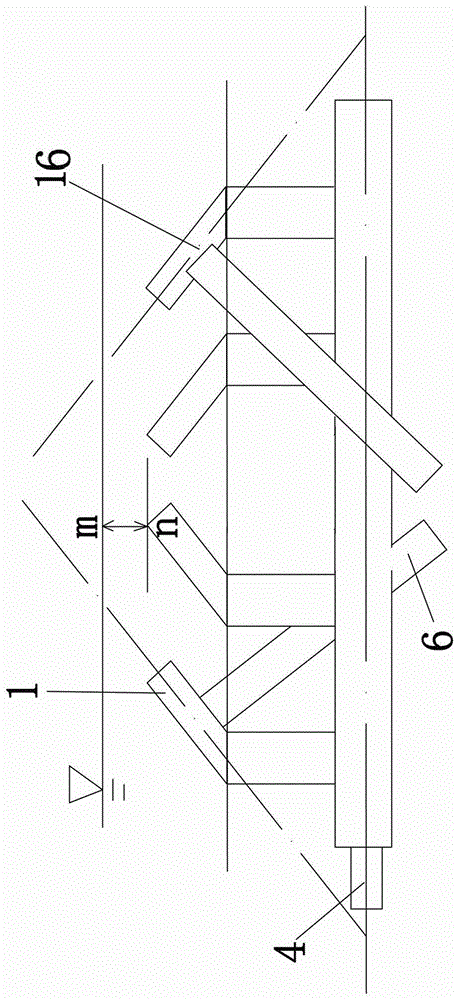

[0029] An anti-freezing device using air-water sprinklers, comprising fifty first air-water sprinklers, fifty second air-water sprinklers, a dry pipe 2 and a blower fan 3. The first air-water shower head 1 and the second air-water shower head 17 have the same structure.

[0030] The first air-water spray head includes a first spray head 1 and a first water suction pipe 6 . The water outlet port of the first water suction pipe 6 communicates with the fluid channel in the first spray head 1 .

[0031] The second air-water spray head includes a second spray head 16 and a second water suction pipe. The water outlet port of the second water suction pipe communicates with the fluid channel in the second spray head 16 .

[0032] Fifty first spray heads 1 and fifty second spray heads 16 are installed on the dry pipe 2, and the axes of the fifty first spray heads 1 and fifty second spray heads 16 are parallel to the axis of the dry pipe 2 . Each first spray head 1 communicates with...

Embodiment 2

[0058] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0059] The acute angles formed by the axes of the fifty first nozzles 1 and the axis of the main pipe 2 are all 45°.

[0060] The acute angles formed by the axes of the fifty first nozzles 1 and the water surface are all 45°.

[0061] The axes of the fifty first nozzles 1 form an acute angle of 45° with the horizontal plane at the inlet of each corresponding first nozzle at the same time, and are located above the horizontal plane at the inlet of the first nozzle.

[0062] The acute angles formed by the axes of the fifty second nozzles 16 and the axis of the main pipe 2 are all 45°.

[0063] The acute angle formed by the axes of the fifty second nozzles 16 and the water surface is 45°.

[0064] The axes of the fifty second nozzles 16 form an acute angle of 45° with the horizontal plane at the inlet of the corresponding second nozzle, and are located above the horizontal plane at the inlet of ...

Embodiment 3

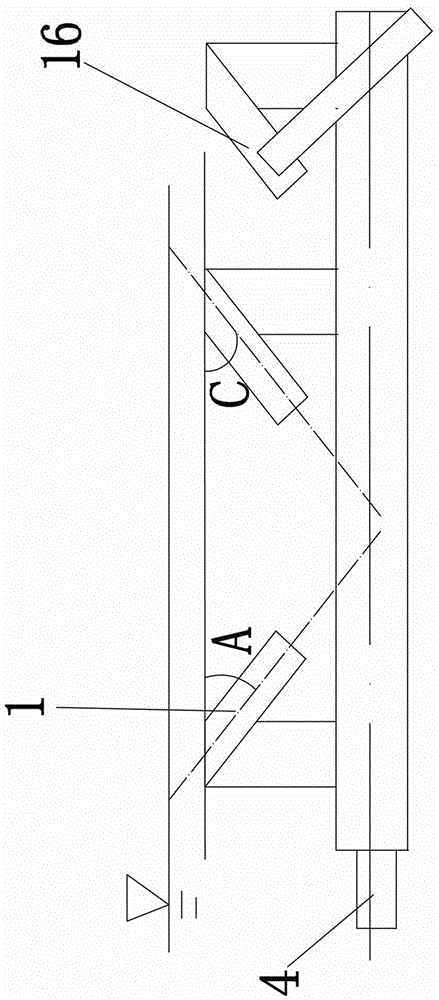

[0070] Embodiment 3 is basically the same as Embodiment 2, except that: the axis of the first spray head 1 is arranged symmetrically with the horizontal plane at the entrance of the first spray head described in Embodiment 2.

[0071] The angle A between the axis of the first spray head 1 and the horizontal plane at the entrance of the first spray head is -45°, which is located below the horizontal plane at the entrance of the first spray head.

[0072] The axis of the second spray head 16 is arranged symmetrically with the horizontal plane at the inlet of the second spray head described in Embodiment 2.

[0073] The angle C between the axis of the second spray head 16 and the horizontal plane at the entrance of the second spray head is -45°. Such as image 3 , below the water level at the inlet of the second nozzle.

[0074] The axes of the fifty first spray heads 1 , the axes of the fifty second spray heads 16 and the axis of the main pipe 2 are all located in a vertical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com