An anti-freezing device using a mechanical stirrer

A mechanical stirring and anti-freezing technology, which is used in the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve problems such as maintenance difficulties, reduce the durability of buildings (structures), and structural damage, and achieve convenient equipment maintenance and ice breaking. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

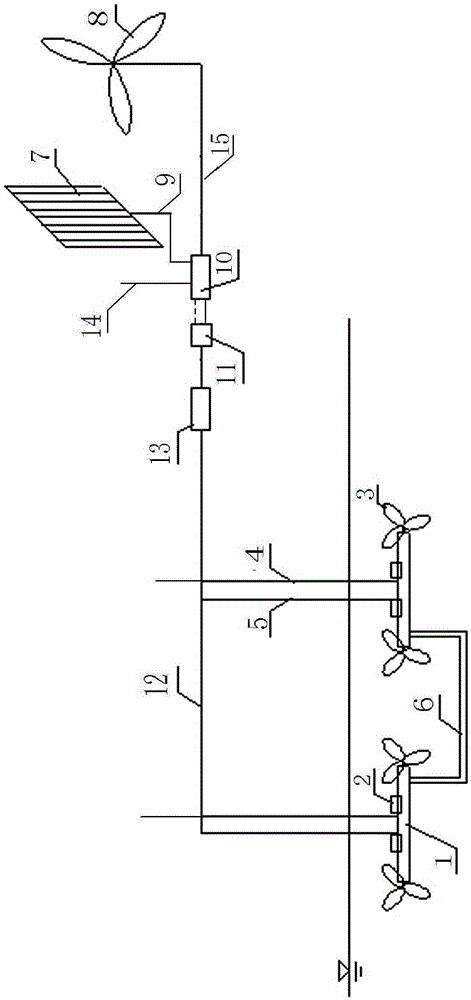

[0019] An anti-freezing device using a mechanical stirrer includes one hundred mechanical stirrers 1 .

[0020] Multiple buoys 2 are fixed on each mechanical stirrer 1 , and adjacent mechanical stirrers 1 are connected by connectors 6 . The mechanical stirrer 1 is a known technology, so it will not be described again.

[0021] A power cable 12 is connected to the output end of the combined clean energy and mains power supply device, and one hundred motor cables 5 are connected in parallel on the power cable 12, and the number of motor cables 5 is equal to the number of mechanical stirrers 1 . Each motor cable 5 is connected to a corresponding mechanical stirrer 1 .

[0022] The combined power supply device of clean energy and mains power is a combined power supply device of wind power, solar energy and mains power.

[0023] The combined wind power, solar power and mains power supply device includes a photovoltaic panel 7 , a wind generator 8 , a charge controller 10 and a ti...

Embodiment 2

[0036] Embodiment 2 is basically the same as Embodiment 1, the difference being that: the axis of rotation of one hundred mechanical stirrers 1 is located below the water surface, 10 cm away from the water surface.

Embodiment 3

[0038] Embodiment 3 is basically the same as Embodiment 1, except that: the axis of rotation of one hundred mechanical stirrers 1 is located below the water surface, 20 cm away from the water surface. The connector 6 is a connecting frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com