A sawtooth weir groove anti-freezing device

An anti-freezing, weir and groove technology, applied in water conservancy projects, open-air water surface cleaning, construction, etc., can solve the problems of loose protective block stones, concrete freeze-thaw erosion, maintenance difficulties, etc., to meet self-sufficient operation, avoid direct Destructive effect, the effect of small operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

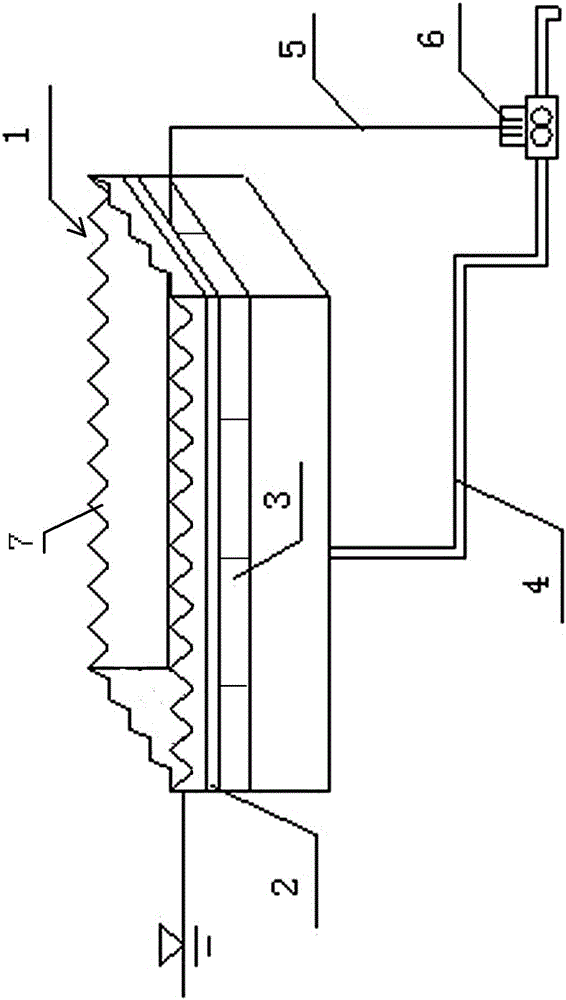

[0018] A saw-tooth weir-groove anti-freezing device comprises a saw-tooth weir-groove 1, a plurality of buoys 3 and a hydroelectric generator 6.

[0019] The sawtooth weir flume 1 includes a weir flume body and a plurality of saw teeth 7, and the plurality of saw teeth 7 are arranged on the edge of the opening of the weir flume body, and form an integral structure with the weir flume body.

[0020] A plurality of buoys 3 are fixed around the surface of the outer wall of the weir tank by bolts. The bottom of the weir tank body is connected with the hydroelectric generator 6 through the drain pipe 4 .

[0021] An electric heating device 2 is fixed around the surface of the outer wall of the weir tank at the same time. The electric heating device 2 is connected with a hydroelectric generator 6 through a cable 5 .

[0022] The electric heating device 2 and the hydroelectric generator 6 are known technologies, so the description will not be repeated.

[0023] The electric heatin...

Embodiment 2

[0029] Embodiment 2 is basically the same as Embodiment 1, except that the electric heating device 2 is an electric heating wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com