Electrical cabinet for numerically-controlled machine tool

A technology of CNC machine tools and electrical cabinets, applied to electrical components, substation/switch layout details, substation/distribution device shells, etc., can solve problems such as troublesome operation and inability to achieve adjustment, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

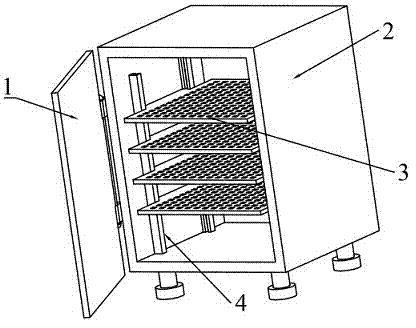

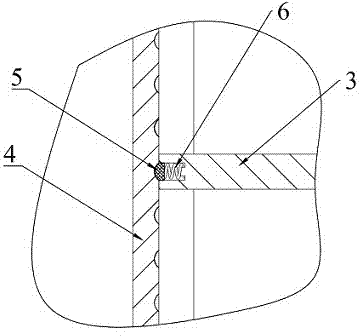

[0016] like figure 1 , figure 2 As shown, the electrical cabinet for CNC machine tools has a structure including: cabinet door 1, cabinet body 2, partition plate 3, guide groove 4, positioning block 5, and spring 6; two guide grooves 4 are vertically arranged on the inner side of the cabinet body 2, The inner side of the guide groove 4 is evenly provided with hemispherical positioning holes along the length direction. There are extending parts in the middle of the left and right sides of the partition plate 3. The extending parts are stuck between the two guiding grooves 4. There are blind holes on both sides of the extending part. There is a protrusion at the center of the inner end surface of the blind hole, the diameter of the protrusion is smaller than the inner diameter of the spring 6, one end of the spring 6 is placed on the protrusion, and the other end of the spring 6 is in contact with the end surface of the positioning block 5, and the positioning block 5 is as a w...

Embodiment 2

[0021] The electrical cabinet for numerically controlled machine tools described in this embodiment, when in use, inserts the spring 6 into the blind holes at both ends of the protruding part on both sides of the partition 3, presses the positioning block 5 on the end face of the spring 6, and at this time the partition 3 The protruding parts on both sides are stuck between the guide grooves 4 on the inner side of the cabinet body 2, adjust the vertical position of the partition 3 up and down, and use the cooperation between the positioning block 5 and the positioning hole to fix the partition 3 and then use it .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com