Rotary electric machine and driving apparatus using the same

A technology for rotating motors and rotating shafts, applied in the field of driving devices, which can solve the problems of difficulty in forming the bottom part and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

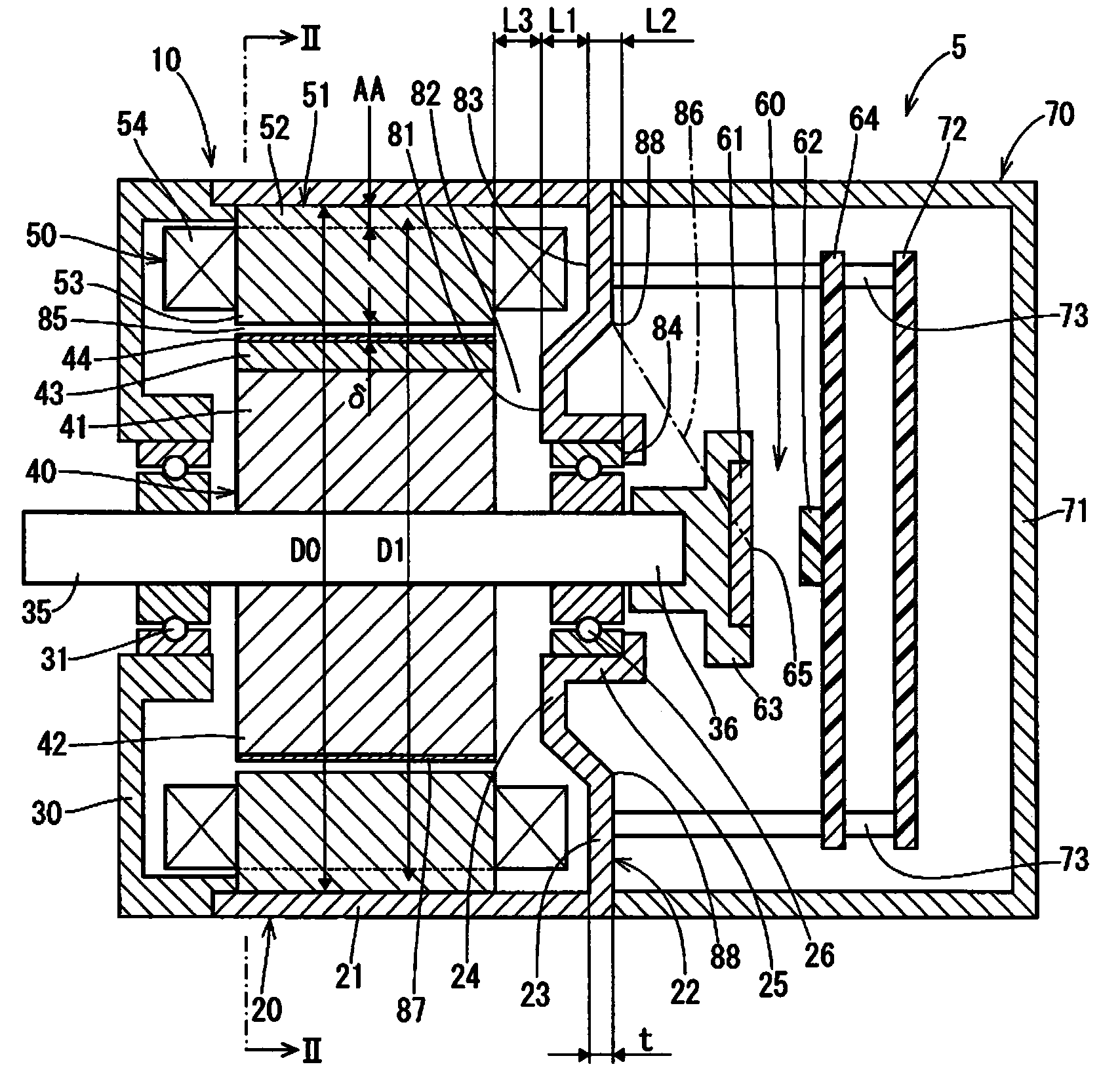

[0019] figure 1 A drive device 5 applied to a motor 10 corresponding to a rotary electric machine according to an embodiment of the present disclosure is shown. The drive device 5 is used as a power source of a power steering system of a vehicle.

[0020] First, refer to figure 1 and figure 2 , the configuration of the driving device 5 will be described. The drive device 5 is a mechanically and electrically integrated type drive device integrally equipped with a motor 10 and a control device 70 for controlling the motor 10 .

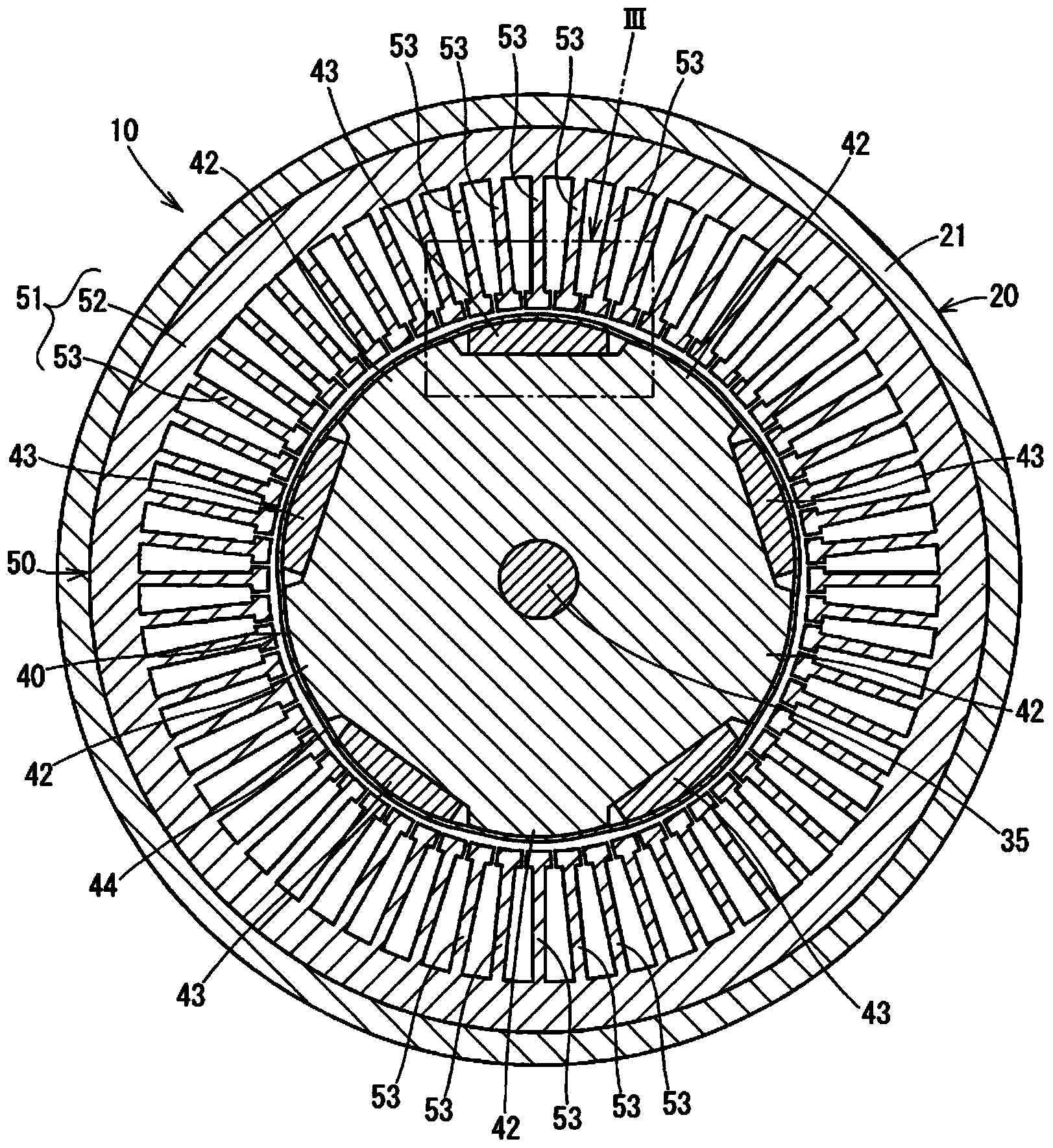

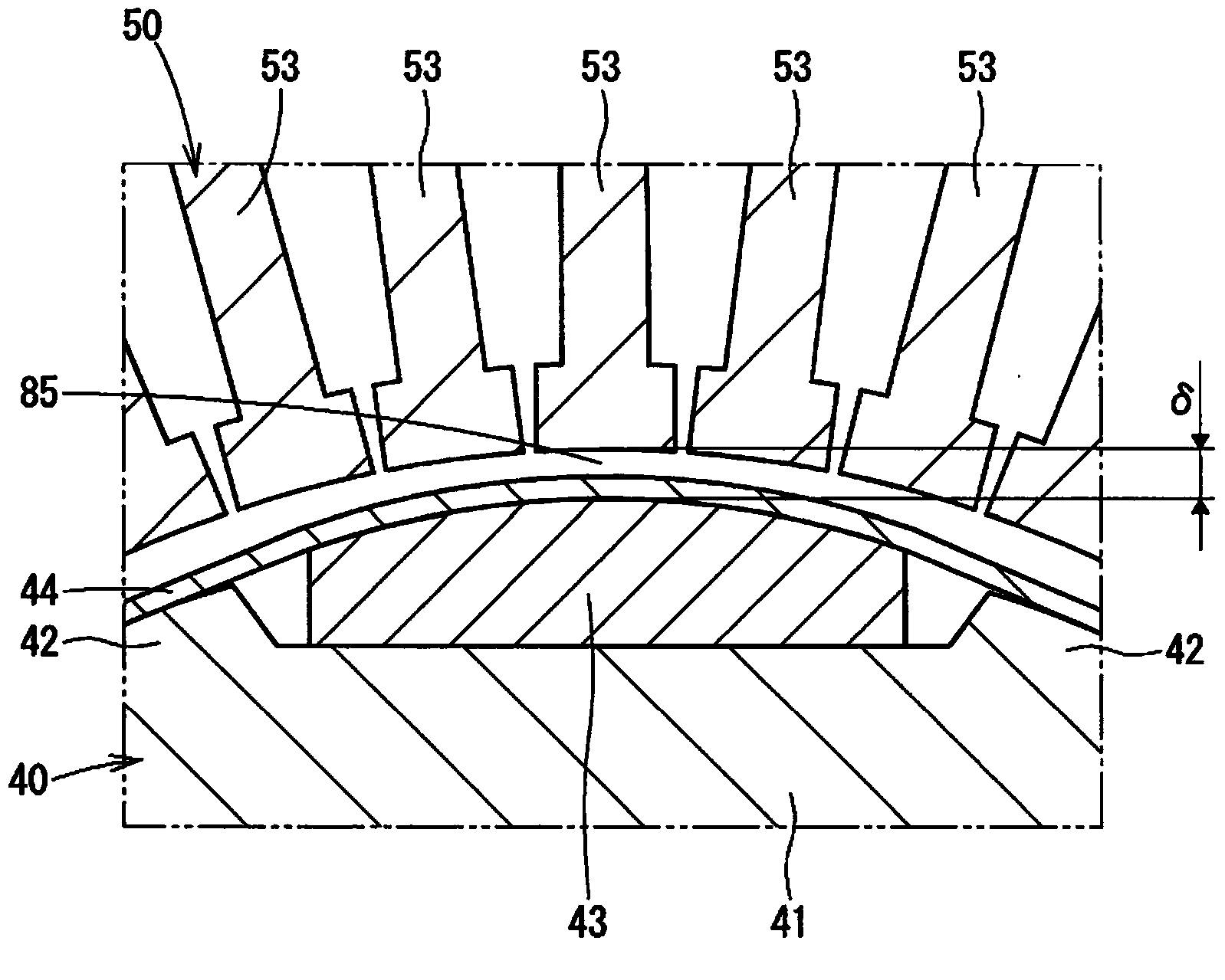

[0021] The motor 10 is a brushless motor having three phases, and includes a case 20 , a first cover 30 , a first bearing 26 , a second bearing 31 , a rotating shaft 35 , a rotor 40 , a stator 50 and a position detection portion 60 .

[0022] The case 20 is a stamped product of a plate member made of soft magnetic material, and includes a cylindrical portion 21 and a bottom portion 22 blocking a first end of the cylindrical portion 21 . The cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com