Stabilizing pin for formed metal plate

A metal sheet and post-stabilization technology, applied in the field of sheet metal stamping manufacturing, can solve problems such as difficult debugging and poor adaptability, and achieve the effects of improving efficiency, strong adaptability, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

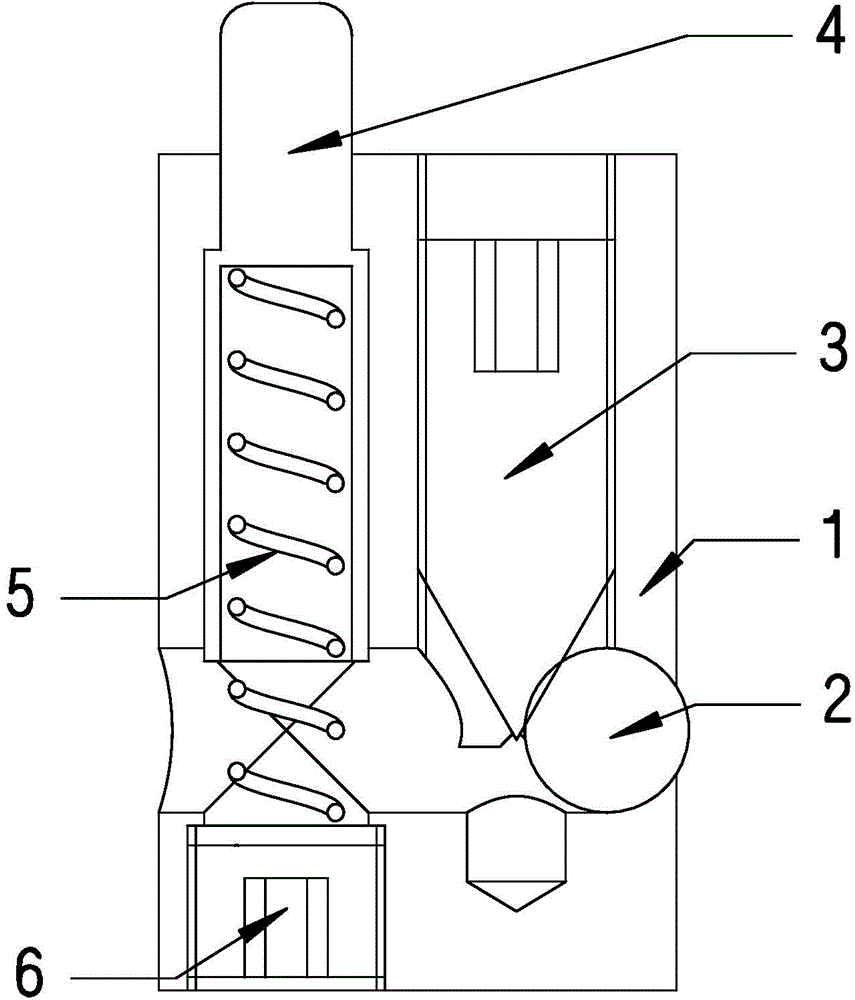

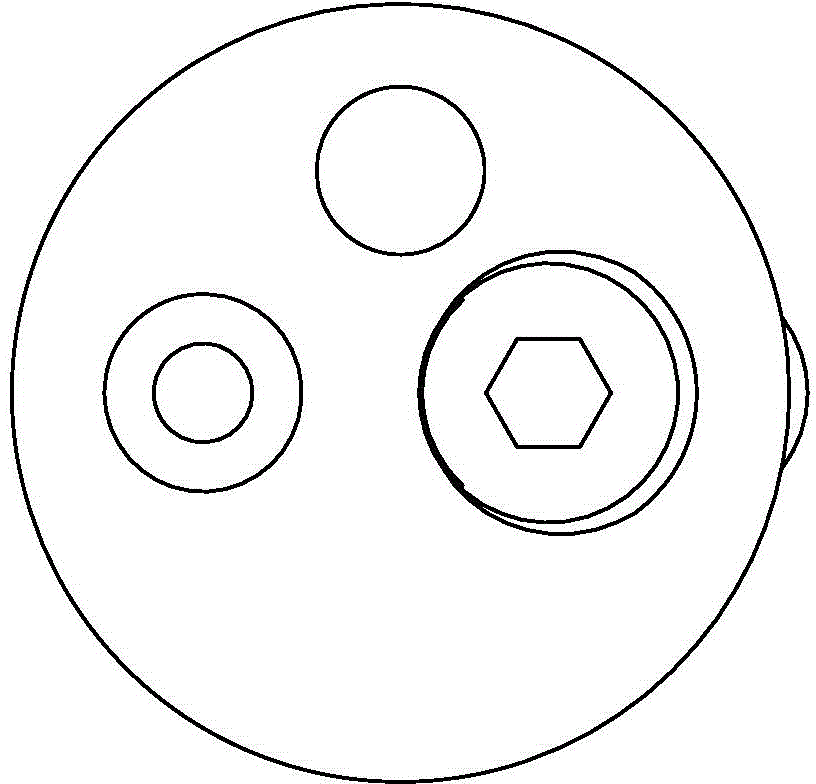

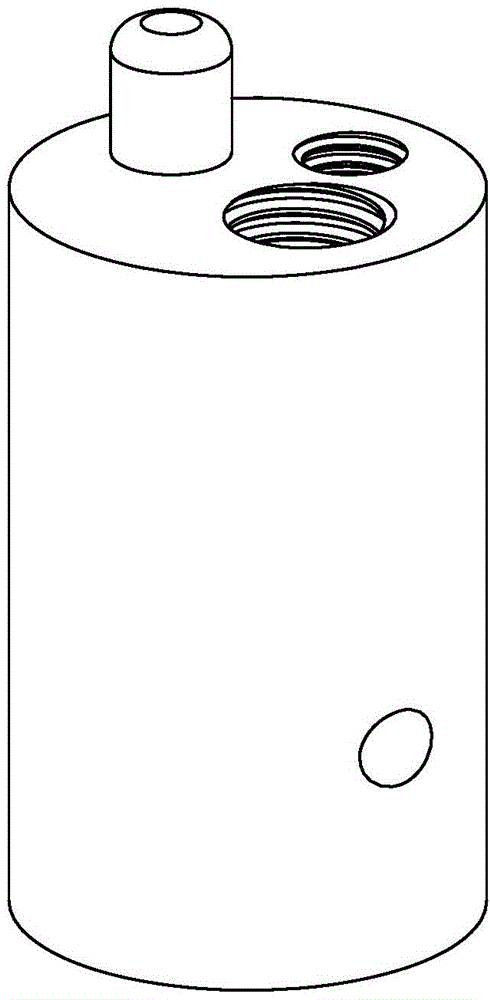

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as Figure 1 to Figure 4 As shown, a stabilizer pin after sheet metal forming includes a carrier 1 , a positioning pin 4 , a spring 5 , a screw plug 6 , a steel ball 2 and a tapered threaded rod 3 . The steel ball is loaded into the carrier from the side, the positioning pin is loaded into the carrier from the back, and there are stepped holes to prevent and limit the position, the spring is loaded into the cavity behind the positioning pin, and the screw The plug is screwed into the carrier from the back to compress the spring, and the tapered threaded rod is screwed into the carrier from the front to compress the steel ball. There are hexagonal wrench grooves on the back of the screw plug and the tapered threaded rod, which are convenient for being screwed into the threaded hole. The length of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com