Clamp used for milling special-shaped samples of galvanized sheets

A galvanized sheet and special-shaped technology, which is applied in the direction of manufacturing tools, clamping, supporting, etc., can solve the problems of sample movement and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

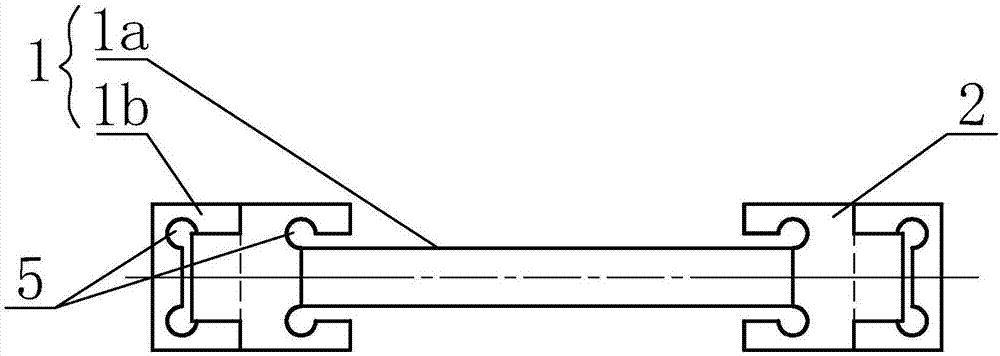

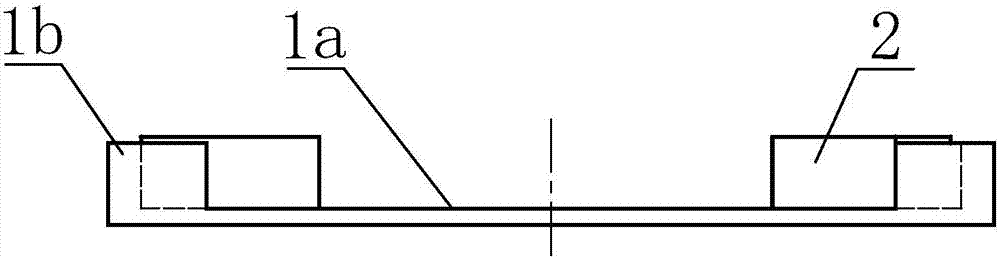

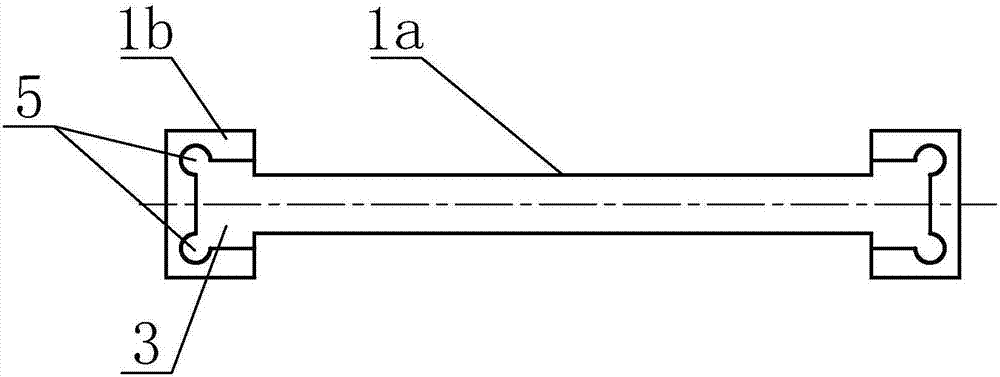

[0022] Such as figure 1 and 2 As shown in and 3 and 4: a fixture for milling special-shaped samples of galvanized sheets, consisting of a limit clamp 1 and a pair of symmetrically arranged combined clamps 2, of course the logarithm of the combined clamps here It can also be 2, 3, 4 or 5 pairs, as long as it is installed on a sufficiently long limit clamp, and can adapt to the placement of different types of special-shaped samples 6, the limit clamp 1 is composed of a limit base plate 1a is composed of limiting ends 1b arranged at both ends of the limiting bottom plate 1a, and the limiting bottom plate 1a is integrally formed with the limiting ends 1b. The inner side of the limiting terminal 1b and the combined clip 2 are both provided with a limiting slot 3, and the outer side of the combined clip 2 is provided with a limiting protrusion 4, and the limiting protrusion 4 is assembled on the limiting end 1b or another pair of combined clips 2 corresponding to the limit card s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com