Special optical cable connection device for oil field

A fiber optic cable connection and oil field technology, applied in the coupling of optical waveguide, fiber mechanical structure, etc., can solve the problems of protective layer damage, limited optical cable manufacturing technology level, inner fiber is easily corroded by hydrogen permeation, etc., to ensure continuity, Achieve strong sealing and protection, avoid loss or even breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

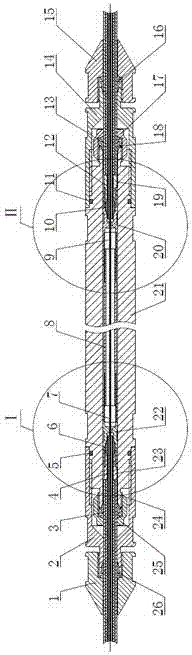

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and the operation sequence of the connector:

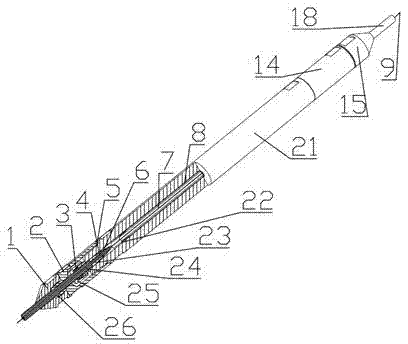

[0017]An oilfield-specific optical cable connection device, the oilfield-specific optical cable connection device consists of a first outer steel pipe fixing and sealing device, a sleeve 21, a second outer steel pipe fixing and sealing device, a first inner steel pipe fixing device, an inner connecting pipe 8 and a second inner Composed of steel pipe fixing devices, the sleeve 21 and the first and second outer steel pipe fixing and sealing devices are sealed through threaded connections and sealing rings; the inner connecting pipe 8 and the first and second inner steel pipe fixing devices are arranged inside the sleeve 21, and the second 1. The fixing device of the second inner steel pipe (4, 12) and the two ends of the inner connecting pipe 8 are respectively connected through the first thread conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com